In yesterday’s blog post, I used 1 micron diamond on a stone and then on cast. The results remind me of something I’d forgotten to some extent thanks to the buffer and thanks to not doing only finish work with planes – the abrasives at really small size cut slowly (they won’t fix any mistakes you’ve left behind) and getting photo perfect finishes off of the scopes is difficult.

But, beyond that, comparing older photos of plane irons honed on 1 micron diamonds, it just looked like the finish was really coarse. I’ve had to change cameras on the microscope – could that be the cause? It’s possible that has something to do with it – the new camera is more crisp and will interpret detail that I think the software in the prior camera would smooth over.

I was puzzled – maybe it’s just dirty surfaces on sharpening supplies that I haven’t used for a long time, but it’s inconvenient when you’re posting blog pictures of 1 micron diamonds on cast and one looks like a sheet of paper with no marks, and a more recent attempt looks stringy and striated. To see what I mean, I’ll show two pictures.

First – the 1 micron diamond finish pictures that I captured doing a plane iron test in 2019:

Older picture of plane iron honed on diamond – either hardwood or cast plate, I can’t recall (at the time, both produced very clear pictures with few defects at or near the edge). At the time, the cast plate was fresh and hadn’t collected any ambient dust or dirt, either)

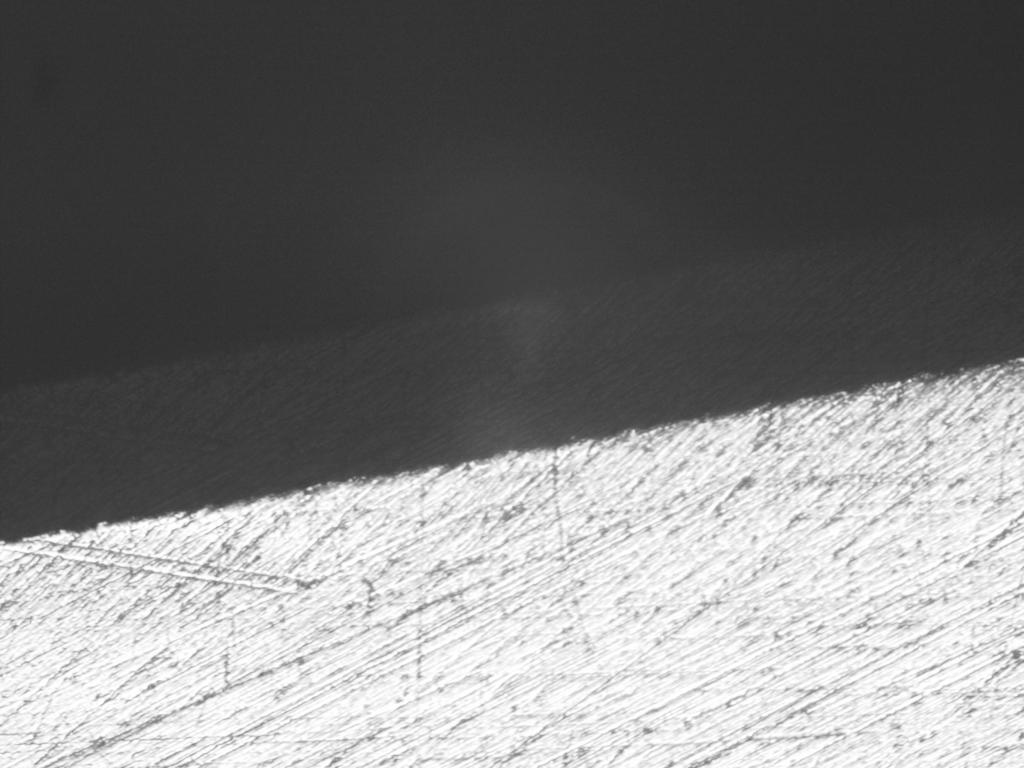

And second, yesterday’s picture on cast (albeit, sitting mostly in disuse since the picture taken above).

Chisel honed – 1 micron diamonds on a finely blanchard ground cast plate.

The top picture is a plane iron, the second a chisel just under an inch. Both of these are blindingly tools with a thin starting edge. Both pictures are the same size top to bottom, and the diamonds used at the bottom are from the same supplier with the same size mark (I lost the original vial). 1 micron.

Later in the day yesterday, I decided that I’d still like to test a plane iron on the black stone with diamonds – recall from the prior blog post or assume based on my comment here, the second picture above is *finer* appearing with a straighter edge than the chisel was on the black stone, so you may expect a picture of the back of a plane iron to appear less fine.

Maybe it would just be better to repost that picture here – the chisel honed on a black arkansas stone with 1 micron diamonds. I realize that these start to all look the same after a while, but notice the crispness of the actual edge. It’s possible to get the edge itself thinner on cast as far as I can tell, and you can feel that in initial sharpness on a plane. The edge off of the black stone is a little less perfect (there’s a slurry of diamonds on it, and probably some stone particles) :

Chisel honed – 1 micron diamonds sprinkled on a black arkansas stone.

And finally, the plane iron honed last night (just a newer surprisingly decent and appropriately hard stanley plane iron that came on a mex-made stanley 4). This honed on the black arkansas stone both bevel and back side (all of these are bevel and back side).

The very first picture had an edge that was lightly stropped on bare leather. Lightly is important because the finer your edge is, the lighter your touch should be stropping – you can deflect the edge with brisk stropping.

The remaining edges are unstropped – they would be slightly straighter looking and the last two, especially, a bit closer to a straight perfect line at the edge.

But notice how fine the surface is on the plane iron vs. the chisel thanks to the benefit of distributing sharpening pressure over a much wider area. I took a picture of this plane iron edge not for the purpose of making this article, but because I was thinking it’d be a good idea to show the difference in sharpness on the black stone with and without diamonds. In my wisdom at the time, I didn’t pay attention and spread the diamond powder all over the stone (the iron is definitely sharper than it would ever be off of only a black stone, an I know that’s hard for some people to handle, but that’s just the way it is).

This also takes away some of the annoyance I had seeing the old pictures and the newer ones done here with a narrower tool. It’s just another illustration of not changing anything if you want to make comparisons, with a sprinkle of “you can vary pressure even with the same tool” and do your last 10 seconds of edge finishing with lighter pressure (presuming the prior work was complete) and get a finer edge.

I think with some further use of the cast plate to remove any filth or light scratching that may have occurred jostling in the drawer, the last plane iron can get a little closer to the first picture, too. If I were reading the blog and comparing 1 micron diamond honed pictures, I would certainly wonder how reliable visuals are if the visuals of the same abrasive don’t make a similar picture.