I heat treat in a propane forge. That generally means I can’t do what’s important for stainless steels, which is a high temperature soak. I can do the other part of the need for chromium stainless steels, which is get a small area of steel really hot. But along with breaking the rules, this is usually highly controlled for temperature and duration, and temperatures that you really can’t get away with in the open atmosphere.

Instead of doing that, I preheat steel quickly to above critical, let it cool just back to where critical would be and then ramp up temperature by eye to as hot as I can as quickly as I can and quench. I’m aiming for almost yellow and not much exposure time to open air and then quench and get to cold as fast as possible. Stainless and high chromium steels often will cool with plates just fine, but I’m just tinfoil hatting that I will come up a little short and I want the quench to be fast.

Is this a long term plan? No. If a stainless shows potential, then at some point, I will either get a furnace or I will send a batch off and give half of them away at cost. But I’m not there yet.

V11 is Somewhat Stainless

A few years ago, two posters on woodworking forums talked about an XRF of V11 showing that it is CTS-XHP. I don’t know if it is exactly, but the composition matched CTS-XHP spec. XHP is a relatively high carbon steel with enough chromium to be referred to as stainless – very high if you’re used to numbers like 0.8 or 1%. I don’t know enough about steel chemistry except to speculate that a lot of the chromium gets tied up with carbon when the carbon content is high and stainlessness won’t just be discernible by percent of chromium because chromium has to remain in the lattice and it even has to remain in the right place in the grains in the lattice. Put differently, a very very low carbon steel may be very stainless with 13% chromium, but XHP is only borderline stainless if you’re really going to neglect a knife.

Why did I bring up V11? I learned that the high temperature soak for stainless steels that frees elements to go back into the steel’s lattice/solution before quenching isn’t just important for dissolving chromium carbides. If you reason that you don’t need to do that and you can just heat it and quench it at a lower temperature, it will lack hardness. As in, you can’t just reason that you’ll work with what’s already in solution quickly and get hardness – it comes up short.

That comes to play here. I’d suspect that if you’re willing to make XHP really hot really quickly and quench it and then run it to the freezer very quickly after finishing the tail end of the quench in water, you can get 60+ hardness after temper. That is, you can get close to the furnace schedule. In doing this, you’re relying on the bars from Carpenter Steel being good quality to start. It seems to be fine.

Here’s another why – XHP has a lot of carbides in it, and it’s a little lacking in toughness in chisels. There’s a little something else going on that I don’t know – it could be volume of carbides (cracks start in carbides) or it could be lack of the same directional property that some other steels have. the following link shows a micrograph of XHP, the white “balls” are carbides, you can read the entire page which is half history lesson at knife steel nerds.

AEB-L, however, is a completely different animal.

What is it?

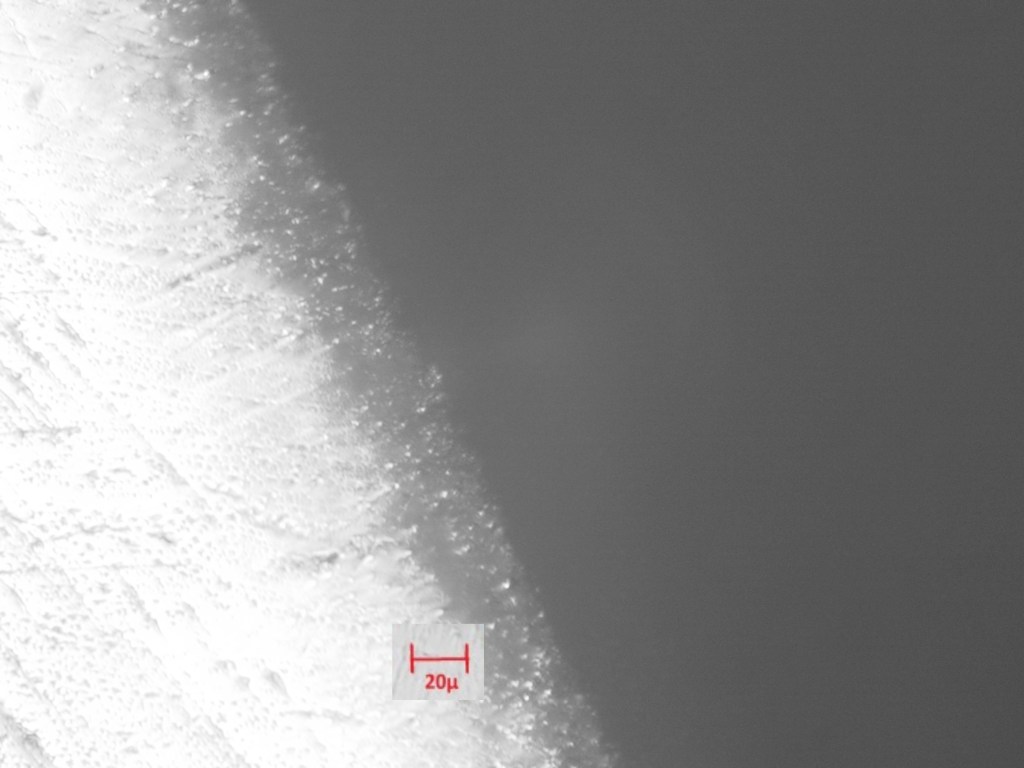

First start with the micrograph (you can click this)

Notice how fine it is? It’s much lower in carbon. XHP is about 1.6% carbon and AEB-L is about 0.67% carbon. A drastic difference. I’ve quick heated it in the past without knowing just how important the high temperature is and it makes a kind of soft iron that needs to have the edge buffed to not fold. Then it planes a long time, but that’s no good.

AEB-L is also cheap – it’s a steel used to make razor blades. Knife steel nerds also has a nice write up on where it’s used. Just follow the link above and search for AEB-L.

An interesting side fact here is the idea that PM steels are the finest grain-wise ignores reality. PM allows steel compositions that would be too coarse if it cooled from a large ingot, but it doesn’t negate the fact that there are other compositions that are very fine without needing a powder process. This results in AEB-L being finer than any powder metal stainless that I’ve seen.

What’s the Draw of Fine Grain?

Somewhere this seemed to imply “it’ll be like carbon steel but stainless”. That’s kind of true, maybe? If you read about AEB-L, it can be done in furnace and finished with a cryo dip after the quench to get very high hardness and still have good toughness. 64, in fact. it should hold up at high hardness better than XHP/V11, be finer grained, and I surmised maybe a little easier to sharpen.

So, yesterday I gave heat treatment another try concentrating heat just on the last inch of the plane iron, quick quench, finish in the freezer. I don’t know what the hardness is, but it must be close to 60 as it shows no ills. It also appears from pictures following that there’s no evidence of suffering anything from not being soaked – for woodworking purposes at least. it would be interesting to see what it’s like at high hardness, but I don’t have the means to get the steel any harder.

Suddenly vs. prior samples, this sample has strong hardness and it’s not quick to hone. Prior versions of this had planing test edge life of 1.6 or 1.65 times more than O1 steel. I’d need to use this iron planing for about 2500 feet in edges just to test that once, and I don’t really have the desire right now.

The reality is that wear resistance makes it slower to sharpen and it is. It also makes it grind kind of hot, which isn’t what we want. It’s not a high temperature tolerant steel and the temper is 350F in the sample here. Grinding it to an accidental brown edge will have undesired effect.

This is part of the conundrum with steels like XHP and now confirmed with AEB-L, too. When you grind these steels, which you’ll be doing a fair amount if you use tools much, the steel wears more slowly and it grinds less cool. XHP takes about twice as long to grind even without considering that and AEB-L speculatively took me twice as long to establish a bevel on a belt grinder. Just estimating based on wear life in wood, AEB-L would grind only about 60% as fast, but that’s compounded further by having to stop more to dip.

Overall, finally getting a hard sample and that’s a little bit of a road block to day to day use (it’s annoying). But it’s worth having a look at how it wears.

This image is the wear after 540 feet. It wears slowly and the wear area looks so odd because of the lack of any visible carbides even at 300x optical . I usually get wear pictures on carbon steels to see carbides at only about 200 feet of planing on cherry. If this iron felt like carbon steel in wood – like in a free lunch way – longer wearing, feels the same – I’d consider planing a volume of wood.

But, it doesn’t. I don’t know why for sure, but I’m starting to get the sense that some carbide volume right at the edge makes for an edge that wears more thinly somehow.

So, this iron would last a long time, but it doesn’t have the feel that carbon steel does, and strangely, XHP/V11 with its high carbide volume has a really keen and sharp feel. Its achilles is that in less than perfect wood, it takes nicks like anything else, or maybe even a little easier, and grinding and honing them out is twice the work.

So, I think I’m back to using plain steels. Too bad. if I ever get a furnace and a dewar of liquid nitrogen, I’ll consider trying to make a very high hardness sample and see if the edge is different.

So…..razor blades? I don’t think AEB-L is ever used in a plain razor blade. I think it’s used as the steel stamping, then it’s honed, and then the edge is coated with something hard. You can see ads claiming razors are platinum coated or whatever – I have no idea what they are actually coated with, but I have honed the coating off of them before when they are dead to see if they can be resharpened, and what’s left is just steel that’s too soft to work at an acute edge.

Steels that d0 well in straight razors rather do have a relatively large volume of carbides compared to AEB-L, but they’re iron carbides and not chromium carbides.

Free lunch yet again not found.

But I have confirmed previously that this steel, which is slower to sharpen but not difficult like steels with a lot of vanadium, will wear much longer than A2 steel and it’s creeping up on XHP – and it’s cheap. About $10 per plane iron in steel costs.

I have no idea if the qualities of picking up shavings more easily during a wear cycle are important to the average user. They should be for anyone who may be sometimes planing several hundred board feet from rough each year as how easily the shaving is picked up is far more important in terms of effort than how many feet are planed carefully in a test. This same factor is why I don’t care for 52100 – it will technically wear longer, but it requires more effort from the person using the plane to keep it in the cut as it dulls and that just isn’t very practical.

For Reference

Here’s how much wear I encountered in the O1 test on the same board after 540 feet. You can see that a great deal of wear has occurred rounding a larger section of the edge and forcing me to increase the light level significantly.