It’s still the same day as posting the prior two posts. I intended to let this sit a while until I had a practical task, but something about the other results didn’t sit right. The results are negative, but maybe it really is just heat at the initial edge. I walked to the shop to think about it and grind off most of the bevel. More than 1/8th of an inch, though that may not have been necessary, I don’t want to inch up to seeing if this is fixed by getting away from the factory grind.

So, I also noticed that I have a few maple shorts left that I’ll never used – I forgot about them. That gives me a chance to bungle up their edges with the cordless circular saw and then plane them and time the planing.

I figure that I planed about 8 minutes on maple with the prior edge in test #2, and 2 in poplar (go ahead and say it…”popular”). So, that’s what I did except I skipped the poplar.

Grinding: uneventful. it grinds relatively nicely, it’s fine and it doesn’t get that hot and at no point was any part of it – not even the very top, hot enough to boil water or burn my hand.

With a belt grinder and ceramic belts, this whole process, even being careful, takes about 5 minutes including installing the updated edge.

Noticeable Change!

When I went back to the stones, the updated bevel is harder to hone. I’m somewhat surprised by this, but I’m a feel toolmaker. Test and observe outcomes, but get feel at the same time. I was surprised how easy the initial edge was to hone, but it doesn’t have bad wire edge / burr behavior, so I ignored it. Maybe it was easy to hone because of the small carbides – this is actually a thing in heavier honing – small carbides will make things a little easier until fine polishing.

This seemed very positive, except it does seem like I shouldn’t have to find the heart myself. I don’t use machine shops for anything, so I can think of (as someone who has done practical heat treating) two possibilities. An exposed bevel that gets heated a bit too much in temper, or one that is ground and even though doused with liquid or cut intermittently – either will work – done just a bit too fast.

The resistance on the diamond stone, india stone and then through the 1 micron diamonds on cast seemed greater, but again, the wire edge came off nicely without any fanfare (this is a good thing).

I proceeded to plane 8 minutes timed, stopping the timer each time I ran out of edge and had to cut some width off with the cordless saw, and then resuming again planing with the timer on.

Far better results

I didn’t bother trying to make this take longer and test several irons against the Magnacut iron – I just wanted to see if the same task could be a little better. By feel, too, the shorts that I had were a little more agreeable than all of the bed slat boards, but they’re still hard maple, and I didn’t baby them.

The edge damage this time is far more minor, and this is an iron that has a better feel of being something I could live with. It’s now slower to hone, but that’s a trade we expect to make with plane irons. I should wear almost as long as V11 in an idealized situation.

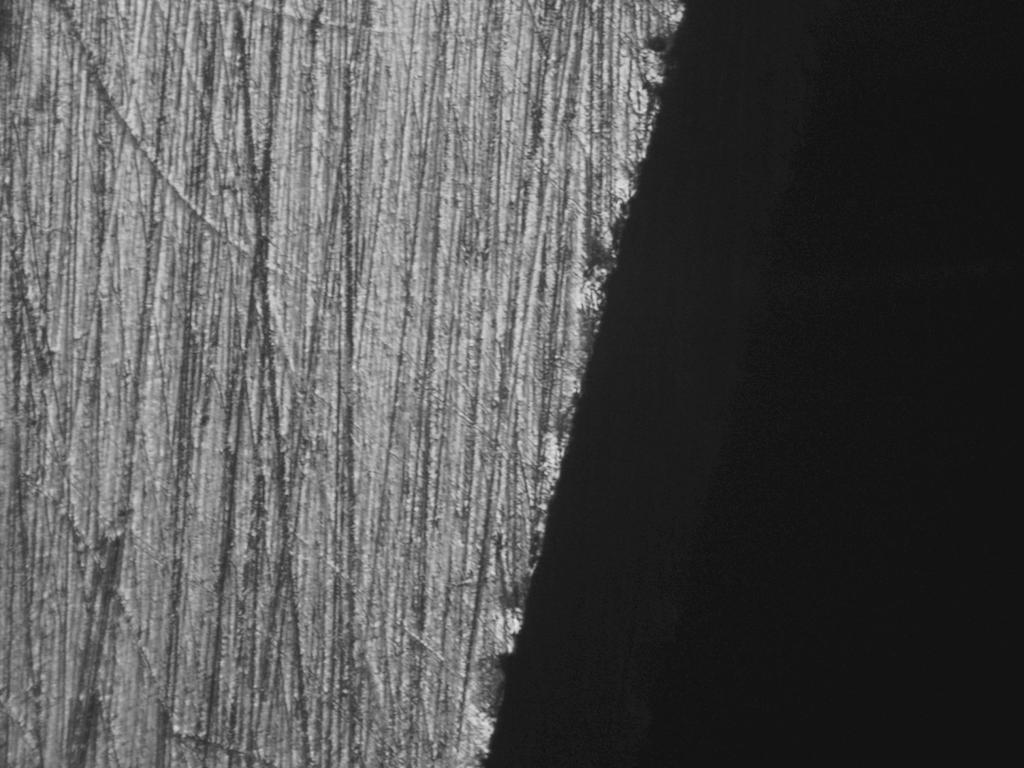

Magnacut 150x – after grinding of significant length – typical minor damage. This is inconsequential and most of the length of the edge used looks like this or better. Regular honing will remove all of it, which is important. We always want to have an edge that has damage no deeper than regular honing because the talk of “stopping to grind out nicks” is something that sounds good in a Pop Wood article, but you will tire of it about like you would a girlfriend who is never there on time but OK otherwise. It makes you wait for something you don’t need to wait for.

Magnacut 150x – typical minor deflection – but even at that, not occurring on much edge length and not worrisome.

Only one more signficant deflection occurred. Fortunately, you don’t have to ask if this is a carry-over from the prior test as I removed a lot of edge length grinding the bevel back.

Magnacut 150x – worst damage encountered in the third test. Wide, but note how shallow it is. Not as bad to hone out. Note that the wear doesn’t look as significant. The wood could be a little more favorable – wear appears to show up as darkness in these pictures.

This is a resounding difference vs the factory edge, both in feel and in the depth of defects. None of these will leave large topographical lines and most probably won’t leave anything you can discern, and a full wear cycle may remove a good bit of them.

Too, with that, just minor buffing (and not edge life reducing large amounts in nature) could also eliminate the defects. And this is on interrupted hard maple.

I am glad I didn’t sit on this, though I no longer have the fervor for testing, I do have it for fairness.

I didn’t expect that the initial edge would be a little underhard (my perception, not proven), but I also didn’t expect because of that, that we’d see a big improvement. As little different as these may look vs. the earlier, the difference is drastic – from intolerable, to usable and practical, at least from these tests.

How much would you have to grind off? I don’t know. I don’t have any qualms about grinding length off of irons and cutting an entire new bevel, but this is a steel that doesn’t tolerate excess heat, so if you are the type who can’t grind without burning carbon steel, you may just want to wait it out if this is a characteristic of all irons.

I mentioned in the prior post that we like to see almost all of the edge totally undamaged, and in this case, almost all of it is.

Now, I can go set the cap close and wear a “cup” of steel out of the back of the iron by letting shavings ride it and we’ll see if we can find a more copious reef of carbides to look at. The point? Only curiosity.

I think this would make a wonderful kitchen knife, but it is out of my league for shop heat treating for the most part.

Though it’s of no consequence here, the other save on this is that I can safely unload this iron – safely as in all in good conscience, and if it had not improved, I’d be more or less forced to keep it and maybe segment it into two very expensive stainless marking knives. I really didn’t want to do that.