The first test was a surprise, but the iron is new, the task was identical, but the planes weren’t the same, and honing was freehand.

A day or two later, cutting bed slats to go on son’s loft bed presented the opportunity to use the same Stanley no. 6 with the Magnacut iron and another plain steel iron – one I made out of 80crv2. This time, the comparison will be a little more than fair.

Edges for both irons were refreshed with secondary bevels at 32 degrees on 1000 grit diamond and then finished slightly steeper (about a degree) on 1 micron diamond on cast iron.

I would normally hand saw wood like this, but to make for a little more to do, I used a cordless circular saw to rip lengths. Without a track guiding the saw, this leaves a much sloppier cut than hand ripping, which we need so that the edges aren’t just planed clear of handsaw marks in three or four swipes.

Cap iron set: same as previous, about .02″.

Wood: 1/2 hard maple, 1/2 poplar (whatever I had to waste on bed slats)

Planing: Alternating the iron every several minutes being mindful to plane at least as much maple with 80crv2 both in actual work as well as time planed.

I made the 80crv2 iron when trying various steels for plane irons. It is marked “80CRV2 A-T” (thermal cycles), which means that it received a low nonmagnetic heat and then was stuffed in vermiculite to cool slowly, and then before hardening, I gave it a series of below-quench-heat (barely critical or subcritical) heats and then one quick high heat well past the furnace target but no soak or hold and quenched and tempered. If it was tempered hard, it would also have an “H” on it, but it doesn’t. So, it’s probably around 61 hardness at a temper – somewhere around 375-400F.

In general, you can think of 80crv2 as something the average white-collar buyer wouldn’t distinguish from O-1, but it is a steel that wears similarly long, but has better toughness. It requires a faster quench to get good results, but it’s also less expensive. It’s more highly regarded in the knife world because it will tolerate more abuse than O-1.

You can also think of it as 1084 with just enough alloying added to make it better than 1084. 1084 is very warpy, needs a very fast quench to hit its highest hardness potential, and will experience very fast grain growth giving newbies little error between growing grain and underheating and ending up with tough but too-soft steel.

For this test, I was careful to avoid any contaminants or dirt, and careful not to be careless with the planes while planing. Maple is relatively hard on edges, but I would say it’s also not totally out of the league of cherry. Whatever occurs in maple will just occur less frequently or slower in cherry. Poplar is a patsy and I’m sure it didn’t add anything here, but I needed a few more boards.

First, the Magnacut Pictures

Note, I didn’t take pictures of initial edges. It becomes too much in terms of things to look at. The sharpening process and initial edges look the same as the magnacut in the first test. All pictures are again, the backs of the irons at the edge. There’s a second motivation here – I think i like 80crv2 better all around than O1, but I’m not sure, and in the back of my head is whether or not its additional toughness may be a detriment. I haven’t used any of these mule irons too much other than just to compare. I expected that a steeper honing guide edge would perhaps help Magnacut and different wood and a different task may help eliminate issues that are one-time in nature. E.g., if there was something in the face of the cherry that I wasn’t aware of or who knows what else.

Magnacut – 150x – edge wear on an undamaged section. The sections

“coming unglued” are wear. They don’t wipe off. Undamaged lengths weren’t uncommon, but they weren’t close to uninterrupted, either, unfortunately.

Magnacut – 150x – edge wear and typical minor deflection. This is no big deal and will probably be removed with regular honing. If all of it looked like this, it’s possible that additional planing would round the edge and the damage would stop.

Magnacut – 150x – more typical damaged sections. Damage of this size (at the bottom) leaves visible lines and you’re unlikely to hone the damage out with a normal maintenance honing.

Magnacut – 150x – worst damage. Within 10 minutes of planing, the planed edges were loaded with lines, but one was prominent. I knew I’d find something like this. There was no “big knot” or anything that caused this, so I don’ know if it started somewhere and propagated or occurred all at one time. You will spend a couple of minutes on a coarse stone to remove this and be back to the grinder with much less honing. Too, the surface that’s left isn’t acceptable for anything.

Magnacut – 300x – a relatively undamaged section viewing at high magnification in search of carbides. If you look very closely, you can see a few tiny whitish dots. those are carbides. I may plane an edge of clean wood later with this and 80crv2 with the cap set close to see if we can get a better pattern. The damage at the edge here isn’t fabulous, but it doesn’t really threaten much or leave topographical lines on work. Keep in mind, this picture is a hair under 1 hundredth of an inch of edge length.

Second, the 80crv2 Pictures

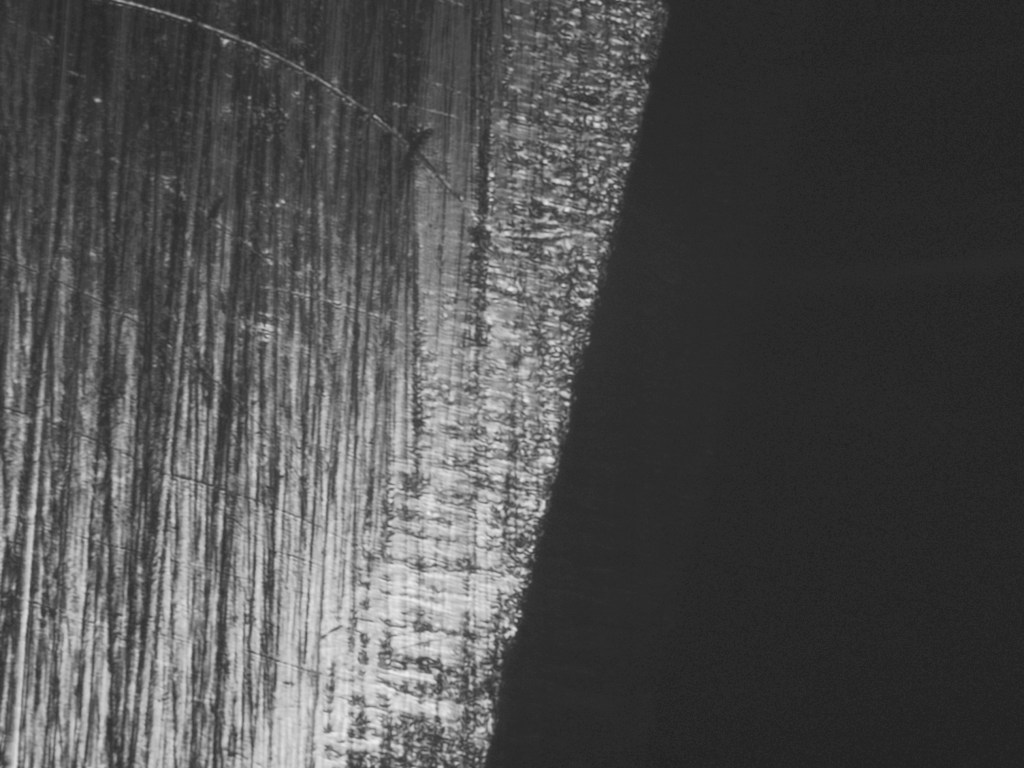

80crv2 – 150x – typical edge length. There is only one spot of damage on the entire length, so there’s no need to show several sections of undamaged length. See the next picture for the only damage that occurred.

80crv2 – 150x – the only observed damage at the edge. This should be removed or close to it in a typical honing section, but this iron has more edge life left and some of it would be worn off of the iron’s length if no more occurs.

80crv2 – 300x – close look for the carbides. Hard to find here but you can find small light colored dots here and there. the diagonal lines may be careless sharpening on my part, or they could just be oil that didn’t get fully wiped off. Simple steels are somewhat tolerant to

The take-away from this is that at the very least, I will grind off the bevel of the Magnacut iron and reestablish an edge that comes from steel further into the iron. That may help.

If it doesn’t, then the solution to get the edge to last is to start adding buffing or additional total angle. Where that would start to help is something I’m not sure of. At 33 degrees or so in this case, it’s about as steep as I’d want to go for a target for daily use and increasing the initial edge angle shortens potential edge life, regardless of the side of the bevel it’s on. It may improve actual edge life, but I’m not going to set up a bunch of “not actual work” tests to try to figure all of this out. I have the need for some cases made of cherry in the next couple of months and if I don’t get to them sooner than that, I will get an idea of the reground edge in that work then.

It should be uncommon to find high-cost tools with overheated initial bevels, but one never knows.

On the second little sub-topic of whether or not 80crv2 is better or as good as O-1 for my own personal use, in knives, it definitely is (takes twice as much energy to break at 62 hardness). I’m not sure in planes, but would also say that what little damage shows up here is inconsequential.