I’m reposting the Unicorn method here as the article that used to be on Woodcentral is for some reason, no longer active. That could be an accident, or it could be because one of the long-time sponsors (Veritas/Lee Valley) had a chisel that did not show well in testing in the article – you’ll see that here when the test results are on a separate page and you can see how each chisel fared with a variety of edges. Breaking this up into several pages with an index will be a better format, anyway.

What is the Unicorn Method, and Name Background

First, a brief explanation of the method – before you do any of the things here, you can work the back of your tool on a fine stone because everything else follows on the bevel side. Then, do the following:

1) Grind a long shallow primary bevel, probably about 20 degrees – anything close to that is fine.

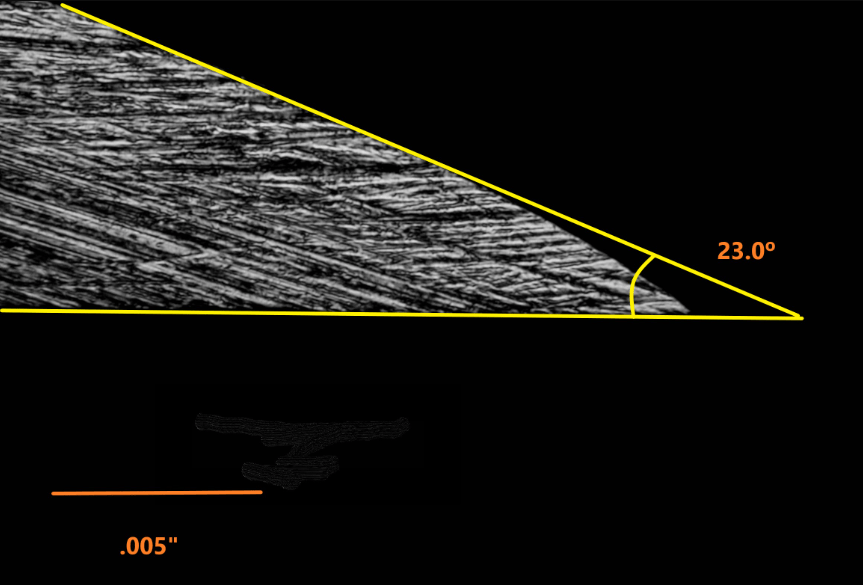

2) Then install a secondary bevel several degrees steeper. I never measured this when experimenting, but demand during discussion later led to taking a picture of a chisel, which showed an estimated 23 degrees or so just setting this bevel by feel. If you know anything about chisels and edges, or knives, you’ll assume that this won’t hold up in wood. It wouldn’t.

This secondary bevel can be installed freehand or with a guide, it doesn’t matter, and with a stone that is a step off of your finest stone. Anything from a settled in fine india to a 4k waterstone or whatever would do fine. There is no need for a fine stone here unless you want to work the back of a chisel or whatever you’re sharpening since it won’t get the last step in most cases.

3) The last step is what finishes the job. Run the chisel or gouge that you’re learning with into a high speed stitched cotton buff with a 2-5 micron honing media. Do this more steeply than the bevel, buffing the bevel side only. Push your chisel into a stitched wheel – see equipment needed to see examples of a good wheel. Push the chisel into the just for a couple of seconds, but firmly so that you’re getting into the backbone of the wheel.

The buffer puts a lot of linear footage on an edge quickly, it does it without much support for the abrasive, so the combination leaves a very fine contoured surface that doesn’t form a burr, and a fine burr left from hand honing will just be removed. No further stropping after it. A chisel can be sharpened in a minute of total time and you will have to be uncommonly good at sharpening to match it.

I will discuss further how you can get in the ballpark if you don’t want to use a buffer. I would use a buffer – I think the speed and the ease and how it leaves the edge is better than other methods (drill mops, or something else similar) and there isn’t much around the wheels on a buffer to interfere. Too, the inexpensive harbor freight type 6″ buffers will do this as well as anything, so don’t go looking for Baldor buffers or something like that looking for “better performance”.

Now, the name. this edge will last longer, penetrate wood more easily and leave a better finish than most anything else you’ll do in combination. It’ll also be faster to create and if you don’t try to cheat somewhere (don’t skimp on keeping the grinding and honing fresh), on chisels and gouges, it’ll create a combination of properties that is difficult to get or seems like it shouldn’t be available – like finding a unicorn.

When we started discussing this, one or two people referred to it using my last name. I don’t care for that as I think it’ll be perceived elsewhere as branding and I’m against that sort of thing. Some variation of this is everywhere – the only thing I did was “discover” something that’s done or was done before and then narrow down what makes it work better than just “buffing tools” without any background.

Two Pictures Before Moving On

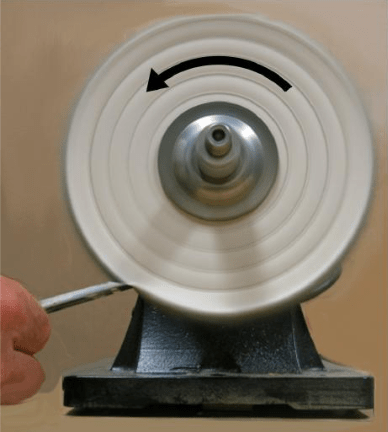

First, what it looks like introducing a chisel to the buffing wheel. Bill Tindall took this picture, but he’s fine with it being reposted here and I see no need to make another one.

Notice how the chisel is into the stitched wheel a little bit. Wheel stiffness increases quickly as you move in toward the last stitch. Notice also that the chisel is “under” the wheel where it won’t catch and even if it did, not much would happen.

Now, the second picture, the edge. Keep in mind, this wasn’t theorized. I intentionally never looked at an edge before taking this picture – it shouldn’t be necessary, and it wasn’t necessary. I’ll bore you separately with how I ran into doing this – it’s a story of functional laziness dealing with a hard to sharpen tool that I use making guitars. At any rate, the line: you grind and hone shallower and shallower until the edge doesn’t hold up – you’ll find that point, where damage goes through the modified tip and into the next bevel. If you get there, it’s too shallow. But talking about this created the typical “how long, how many thousandths, what angle” questions that I was hoping to avoid. Those are small, too small to observe so we get to them by feel rather than by taking pictures and comparing things on the half thousandth level. And thus, I honed the side of a chisel and took this picture.

I can’t resist adding a third picture, we’ll call it picture 2a. This is what the edge will look like to the naked eye. The little “white stripe” at the very tip is the rounded edge reflecting light back toward you – i’ll be able to see it.

Back to the black background picture: note that the entire flat line is secondary bevel area, not primary. The buffer does something with a couple of thousandths, progressively more as the tip is what gets into the spine of the buffing wheel. Notice how there is no burr hanging off of the tip – it’s honed off and crisp.

Note also that in theory, the “honed” edge would’ve gone to the apex of the lines, but in reality, when you’re honing by hand, you won’t ever actually do that. We are essentially modifying the very tip of the tool edge where damage starts so we don’t rob ourselves of abrasive edge life by getting damage that creates bigger problems. If you think this “rounded” edge is thick and will be hard to push through wood, imagine what it would look like with nicks and steel sticking up several thousandths above and below, and you’ll be trying to push or mallet that through wood. No good.

And when you start to separate the very tip of an edge where you want to stop damage from the rest, you see this all over the place. On a straight razor, we use a linen and strop. The pair modifies the edge just enough to prevent damage and you can shave for a year every day with little edge degrading and hone on your finest stone for five minutes at the end of the year and avoid all of the nonsense that’s propagated on razor forums with honing away a good razor and ending up with something that performs less well in the process.

I will spare you pictures of razor blades, but this deflection that occurs on a virgin atom thin apex or anything close to it is why you dispose of disposable razor blades, not wear. Linen and cordovan leather on a straight razor halts that and you can shave your lifetime with a single straight razor without consuming much of it.

No feedback on this article so far. Have there been any updates?

Raf

P. S. The article in Woodcentral is up, one just needs to search for it.

LikeLike

No updates to the article. The whole process is a lot more nuanced than just getting an edge to stand up – in terms of flexibility, but it’s a little bit TMI and the reality is, there is no big market for the level of discussion. If I were a shyster, I’d think about turning it into a $10 course, and then maybe people would be more interested.

I saw that peter got everything up and organized. The whole kind of irritation with the situation there – and inaccurate memory of some folks about what was going on with the site (it was declining to the point of near no hand tool traffic – though still knocking out 100 posts or 150 posts week in the main side)…all kind of blown over. If anything, the site is a candidate to become an ad trap like the UK workshop site where it’s optimized to get hits on google and then whack people with a big full page video ad on the way in to make a few bucks. The entire online community is pretty much dead. Strange to say it but I think even a forum is too close to social interaction where people know who you are and the rest of the online community that thrives now is kind of a perverted antisocial setup. One person sells, the other person watches in anonymity and thinks they’re viewing someone who would make a good friend. Nobody learns anything new except beginners. It’s weird!

LikeLike