Not much of this blog has to do with buying tools. Why? Because you eventually start buying stuff to make things rather than tools to imagine doing it. I did the latter for plenty long, but I’m out of room for practical purposes and I never wake up on a Saturday at this point wanting to go somewhere and buy tools or getting on ebay and just checking the new listings of stones or hand tools.

And the whole flea market thing was always intermittent. The buildings or booth markets get picked over by flippers, and the local flea market here that happens on a regular basis is first hit or miss at best, and a time soak, and second, usually looted by a dealer who takes advantage of the ability to set up a booth and go buy everything that’s really any good before the market opens up to the public. I think that whole “dealers can buy anything that’s actually a bargain first” is the shits, but I guess it attracts the dealers, and the dealers pay for a space at this particular local flea while the patrons don’t.

Flea Markets

It was sort of a sport online to go to flea markets in the mid 2000s when I started. You can get all kinds of stuff at fleas, but usually it’s another of something you have or something you don’t need because it’s a good deal. I bought a lot of that – another smoother, another three socket chisels, and so on. Every time I had an immediate need, it was never at a flea market with the exception of one single time – metal vise.

But I would buy other stuff and some of it I’ve used. The strike rate isn’t great, though. Most of my better tools came from online shopping, and I guess that’s an expensive way to go.

My mother is making a slow trip, it’s the end of one that starts with memory loss, and it puts burden on my dad, though she’s now in a facility. I visit home, four hours away, far more than I ever did in the past. Every three or four weeks, I drive past a building of flea market stuff thinking “i’m going to stop just to look in there”, but the feeling having crossed over to making is what will I buy and should I just save my money instead – there’s kids going to college in a few years, a cranky mrs. and hopefully funding for an early retirement. We’ll see.

I finally stopped last week. And somehow, I don’t have the urge to do it again because the results were better this time than they were when I had the bug to buy rather than the bug to look:

There’s one more thing missing from this that I forgot about – an old hand made pin gauge with a wooden screw. it works wonderfully. the only thing in this picture that I didn’t pick up is the cherry box bottom the stone shown is in.

I love a panel gauge, but have only one – the stanley pin panel gauge with a brass liner but all rosewood stem and head other than that. it’s a nice gauge, but I’d love to have one that could be fitted with a pencil. And I have to apologize for the picture here, because the opposite side of the beam is a treat here. It’s hand marked, very precisely, and the numbers written in for measurements at the measurement marks are done with charisma completely by hand. The pin sits in a round socket on the other end and needs to be replaced, but I think I can manage that. I can make a filler that goes in the round bits on the other end and use this gauge to mark with a pencil. Why not make it? This gauge was $7.

The little Arkansas finger size stone at the top , or pocket stone, is something I use to surface finish stuff that’s been ground so it doesn’t look like cheesy ceramic belt look, and the little green stone is one of the finest hand hones I’ve ever seen. I think it’s probably English slate, but it was about $3.

When I got to the counter, everything shown and the missing pin gauge was $30. The slip on the right is washita, and there’s a second one under it. I have india slips and a trans slip, and they work fine, but being a buffer of things, washita following the india would make more sense. It never was urgent enough to want to pay anything significant online, but at $5 for a pair of slips, I’m in.

My eyes were bothering me that morning, so the white ark stone, I thought maybe it was a washita. I have no idea – but it’s novaculite. it’s a little aggressive and an odd size, who knows. the green stone and the ark stone, I did think “why am I getting these?” and still kind of feel like that. they don’t address anything and it’s true that I have more stuff like them that I probably should sell rather than add to. But the two together were somewhere between $5 and $7.

When I was looking for something, I never found anything that was a deal outside of one type 1 millers falls smoother. that I didn’t need – it just stands out as one of the few things that weren’t full market or close.

The Other Option

Ebay and online sellers often have stuff far more like what I’m looking for, but at the moment, nothing that I need. I do have a turkish oilstone, but it’s light brown and i’d guess the light brown stones weren’t as highly regarded as the black stones that looked like they’re covered with fractures.

Last couple of weeks, someone on ebay posted broken parts from bigger older turkish oilstones, and most days, I’d wait a little bit with some internal argument and someone else would buy them.

But This time, I struck. this stone has enough obvious characteristics to show that it’s a legitimate turkish oilstone and not a currently-available cretan stone that you can get for $60.

it’s also the first time I’ve seen something of size that isn’t eye bleedling expensive. it was about $120 or something, which is a lot of money for a stone you don’t need, but it’s a stone I won’t probably find again with as little as I’m looking.

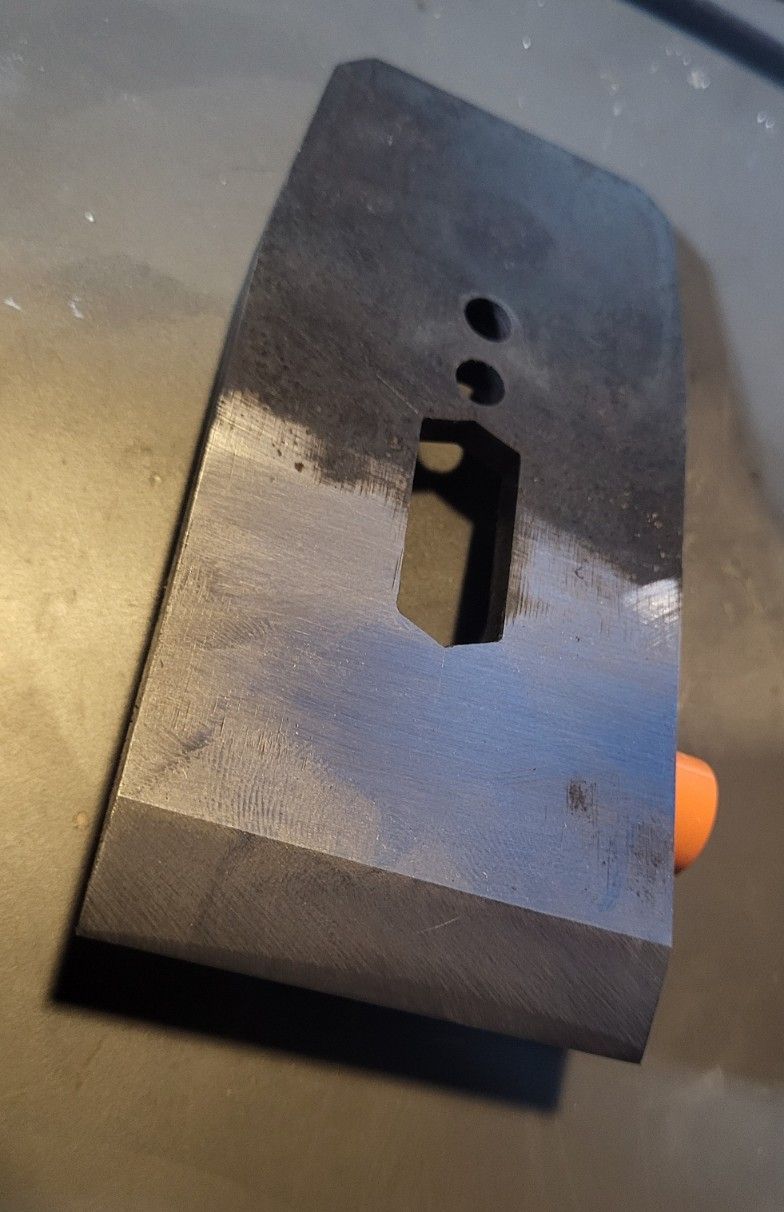

The deal with a lot of these is even if they haven’t broken off, the undersides are irregular and you have to fit them into a box. if you dropped this stone, it would break into a million pieces, and at the bottom, you can see the box fit is pretty bad. it wasn’t at first, but I took a hammer and tapped the thin tail off of this stone while fitting it It didn’t serve a purpose. Since the picture, I’ve lined the fitted box with plaster as the front and the back of the stone taper and need support. tung oiling and then topping this box with varnish will keep it from getting black right away.

I’m looking forward to seeing what the stone is like. the turkish stone I already have is slightly friable, but still immune from gouging with tool tips and this one was sold as soft and fast for a Turkish stone. It doesn’t feel like it’s very coarse, still – figure something like a 6-8k waterstone type action, but with a far better feel not such a fragile face. The surface is continuous and none of the lines in the stone are actually open. In a couple of days, everything will be dry, and if it’s interesting enough, I’ll see what the edge and speed are like compared to other stones, and maybe leave a post about it.

Side comment that goes with this – thank goodness for coming across the buffer – that one discovery had really curtailed much of this stone buying. I’m sure if not for anyone reading this, that it’s saved a few other folks plenty, too – from falling into the trap of buying gimmick multi-hundred dollar synthetic stones, and “systems”, too. It couldn’t quite save me from blowing money on another Turkish oilstone, though.

.

.