I stopped reading reddit – it was interesting for a while, like shopping at a different buyer’s club store for a while, and learning some new words.

Astroturfing – creating artificial impression of public genuine feedback on items and I guess there probably already is a definition of what follows after that. A snowball where marks (as in of mark and con) begin to add to the astroturf with glowing comments. If this kind of effort goes through influencers, in my opinion here- because you’ll never get an influencer to reveal how much they’re getting or in how many other ways – you get people like James Wright pushing Zen Wu tools.

Behind astroturfing and the snow ball, you first have a product that appears to have some positive differentiation. I’ll leave that to other peoples’ opinions, but what I see is tools that are either cheaply made, or they’re made in an expensive way that’s pointless. Cheap in chisels is slab bar stock stuck in a handle (check, that’s there), and pointless is titanium, for example, with expensive milling for a bottom layer of steel. The draw for the mark is not naming the steel and making people think it’s exclusive. It’s never going to be with the rare exception of an alloy exclusive to a very few inclined folks. Magnacut is the development of Larrin Thomas. It’s a genuine effort, and what it does is novel, but there is no hiding what it is – Larrin wants to celebrate what it is and pretty much tells you everything about it from the composition, to micrographs, etc. Larrin is legit. The world of woodworking astroturf isn’t. I don’t really see the point of Magnacut in woodworking tools, but I can guarantee if I emailed Larrin (I think Larrin doesn’t care too much for my way of doing things, but he’s too quality of a guy to just tell me that, and he still will answer any question I ask – I respect him for that, too. I would answer legitimate questions of people I don’t care too much for – buddies and information are kind of separate to a point).

At any rate, here’s the key elements to the mark formula:

- An influencer who has never really done significant work and really doesn’t have a qualified opinion about anything other than influencing. Once in a while, you’ll see a professional go off the rails which looks like they’ve given up on being legitimate, but the world of social media has generally brought us people who started with no skill and haven’t gotten far. Stumpy, Animal Trades, Wright, etc.

- Information that comes through the influencer that seems to be novel. It may actually be new and not related to you being a better maker or really benefiting you at all in any way, or it may be copied (“the last finish you’ll ever need” – with every mark farmer offering to let you know a secret – that you can mix an oil, a thinner and a varnish and rub it on things. “psst…don’t tell anyone!!”)

- The implication that the influencer isn’t really in on a gig. The selling is just ancillary, or hidden in token links and not discussed.

- Offering something and getting an uneducated base to make a comparison. Years ago, for example, someone offered 3V chisels. They were all the rage. 3V at the upper end of its heat treatment range would make a decent chisel. It wouldn’t make a great one, but if you compare it to a chisel that isn’t very good, it will look good. The blueprint for a superb chisel is probably 200 years old and but for affordability of the materials improving, has not been bettered.

- A huge group of individuals who really don’t know much then praising both the item being sewn into the field of fake’s playing surface as well as the influencer.

- A group then reading who just is really itching to buy and has lost sight of the hand on the keyboard and the other on the bench – it’s a dopamine trip at this point, I’ve been there – that group is looking for confirmation that they can get in on the excitement. And maybe buy some competence.

There’s another odd byproduct in the woodworking world. The people who actually make stuff and sell it are viewed as shills. The influencers, who are just grifting a gullible audience are seen as saviors. If you don’t believe that, just go ask about Rob Cosman on Reddit and then James Wright.

You and I don’t really need either of those guys, but the former is a guy who really sells his stuff hard. It should be more respectable than the latter, but the latter is the model for finding marks in greater volume and not being called out. Does that mean I think you should purchase stuff from Cosman? That’s up to you – I think you don’t need anything Cosman sells and just like any other guru, you’ll be on rails if you start believing everything has to be done his way.

The pleasant David Charlesworth got me on rails when I first started. I like David, he certainly isn’t a salesy pusher nor is he a grifter, but if you’re going to work entirely by hand, a little bit from him is enough and move on or you will be stuck. That’s life. None of us needs each other. Nobody needs anything I type about, either, I’m not delusional.

Blue Forum Post

A blue forum post that came up this morning reminds me of astroturfing, but I think the poster is a Mark. That’s what brings up the Zen Wu topic. Someone asked almost exactly a year ago, the post died quickly but then was probably brought back by someone who probably searched the maker and then found a negative opinion about influencers. As i understand it, even Reddit is far behind the wave of stupidity that is flowing in the woodworking world now, but I won’t patronize any real social media sites to find out otherwise. They are a world just as artificial when there is “knowledge sharing”. They’re advertising sites, and when the advertising at the local level goes beyond the junk guy hauling stuff away from your elderly parents’ house and doing you a favor, it’s nonsense.

At any rate, the poster responded “I don’t think youtube influencers are paid”. Maybe in another 30 years, people won’t be quite so dumb. Another follow up as the plastic grass began to grow, though, described that Wright announced that his “go to” smoothing plane is now better than a boutique plane and it has the Zen Wu iron. Of course, that sentence should end with “and if you buy it, I get paid X% of your order amount if you click on this link”. The grass grew a little bit further then with a discussion of $1,500 5-piece chisel sets that were impressive at a wood show.

If I Unicorned a $50 chisel, and put it on a bench, it would snag the beginners at any show because it would be sharper than anything most of them have used. If I made a paring chisel and demonstrated malleting it into hardwood, that’d be pretty interesting, wouldn’t it? It wouldn’t to me, it’s something the chisels can handle, and so can an older Marples paring chisel and a Ward or Nurse marked chisel or anything else. But we’ve gotten to the point that a lot of stuff is marketed at, well, marks, and some of it says you can only push half length paring chisels, leaving one of the tenets above covered – compare the results to another product that isn’t very good.

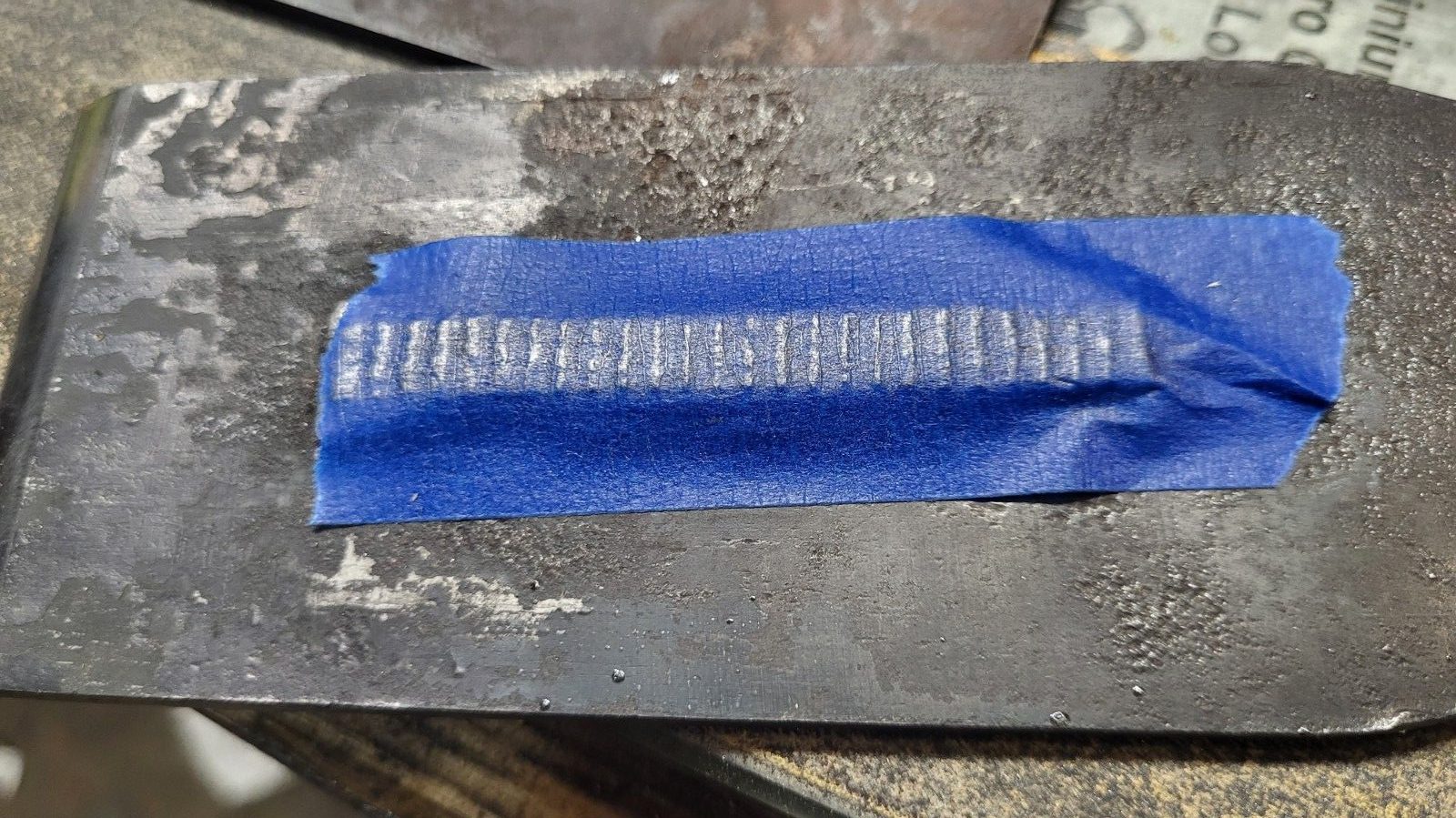

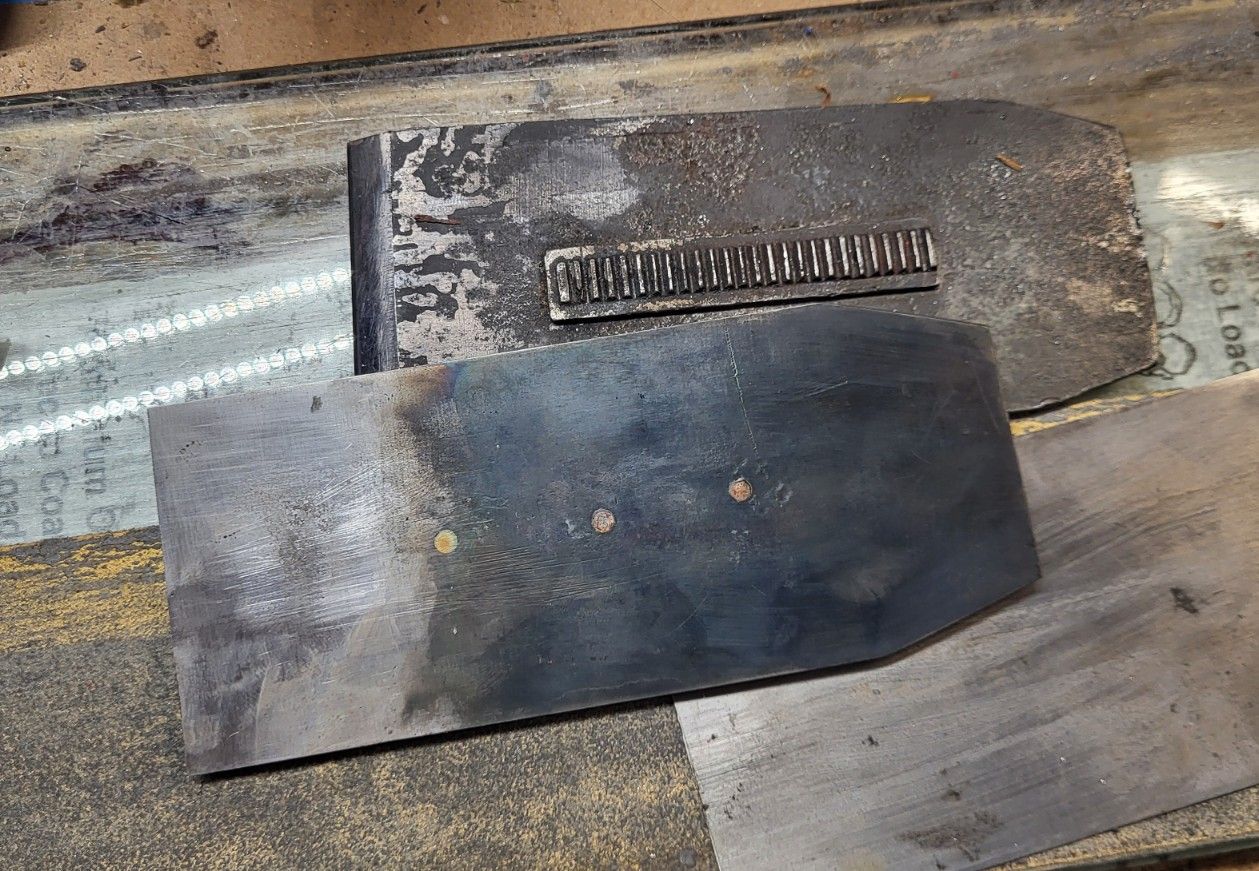

I couldn’t resist seeing what chisels are $300 each, and that resulted in finding a titanium bodied chisel with a dovetailed lower layer. that combination makes no sense. The fake steel name is added to the equation. What is the actual steel? I don’t know, but it wouldn’t outperform 26c3 chiseling wood, and 26c3 is affordable. *you* can thermally cycle 26c3 heat it a step past nonmagnetic for 15 seconds and then quench in brine. You’ll also need to learn to tackle some things like warping, but there isn’t that much there in the way other than desire. A laminated chisel of that type will bend before a solid 26c3 chisel would. Will we see breakage on some of these tools like we have seen with Iles D2 mortise chisels from time to time (those wouldn’t break if they were something else but ingot D2, but luckily the market of users doesn’t really do much using).

All of this stuff – the astroturfing, the self-fertilizing marks and the whole formula makes for a good adventure, I guess. But it has staying power. What is it? I used to think, and probably a lot of folks did, that the whole commission and as in the case with SMC (blue forum) “non-competitive advertising environment” arrangement was good for sort of connecting people to each other and if you’re in the pool so to speak, you kind of deserve what you get.

But participation goes farther than that. My last paragraph implies to you and me and everyone else, “well, no big deal – if you don’t get caught up in that, you won’t ever be exposed to it”. Lee Valley at one point said only about 10% of their customer base perused forums, so when there is conflict, I’m sure they don’t like it, but what they were letting us know is most of their customers aren’t buying from there. I’m sure that’s changing.

As I learned at a sharpening class that I gave (only one I ever did!), one of the attendees floated to the front of the room with a Benchmade pocket knife. It wasn’t hard enough to survive dressing a deer. I can only guess that if you search for a Benchmade knife, you’ll get a lot of hits from social media. The days of getting a catalogue and using that and calling someone to order are pretty much over. Cross contamination here from Stew Mac – the prior post – a good friend of mine remembering Stew Mac the family owned company now long gone was frustrated that there was no phone number to call to ask questions. He ordered something anyway, and was disappointed with the quality compared to what he remembered.

Here’s the point – the efforts to spend in social media and create enough marks to taint the punch everywhere flows back out into searches for information about products. And we see now that forums that die or that haven’t yet get bought by conglomerates like Group Builder – those forums have been indexed by search engines and the users can be solicited for donations and the unregistered folks who are referred to from google will see – last I counted – 8 advertisements including a full screen or mostly full screen ad. Everyone wins all the way around except the folks looking for legitimate information.

The unicorn will save the guy I mentioned by preventing the knife he has from rolling while he dresses a deer. But it would do the same thing for a Chinese-made Buck knife (or a USA made one!) that’s $12.

So, this makes me angry and motivated, right?

Not really, you just watch and observe and shake your head once in a while. I think for anyone who will get serious in the hobby, as soon as you start making things, you quickly find out what it takes and if you never start going backwards in time to more permanent knowledge, you wouldn’t have, anyway.

I think it’s unethical – the whole influencer system, but that’s for other people to really determine for themselves. I’m sure the FTC’s intent is blown up a little bit in terms of disclosure of sponsorship by weasel wording, but again, since the beginning of time, creativity has allowed pushing the limits on the legal or regulatory side of things. There’s no reason to get too excited by that.

I will admit that if I’m talking to someone in a DM or email and they are extracting information out of me and then spring up with “James and Rex do this and this, though”, I’d like to know if you’re going to do what James and Rex advise, when all is said and done so I can reply “I think they’ll be good sources of information from you and you don’t need anything from me”.

I do think the Public Deserves Information

If you’re buying chisels, you may be indifferent about what the steel is, or you may be curious. XRF analysis will out what any of these “secret proprietary” steels are, and there is nothing that prevents you from getting that information. There is no legitimate consideration for “courtesy” here and it’s not illegal or even unethical to spend $35 for XRF analysis and publish what you find.

If I ever make something professionally in the future and don’t disclose the alloy (it’ll never happen), there is only one reason I would do it – for lack of want to use the same alloy every time. For a company like Pfeil, who probably uses 80crv2, not disclosing the alloy may have some to do with marketing, but it also will insulate them from getting bound up in discussions from armchair experts reading knife forums who want to lobby them to use something else. Same for ECE. ECE doesn’t specify the alloy – their metalwork isn’t good enough at this point for it to matter, anyway, but there’s nothing for them to gain.

I would encourage anyone to have anything I make XRFed and hardness tested even if it’s a matter of seeing if I’m honest.

When Lee Valley picked a steel that would be V11, much of the public believed they developed it and it was proprietary. The woodworking boards were abloom with discussion about how it would be illegal to have the steel tested and disclose what the alloy components are because that’s IP. It isn’t, and if LV did something other than choose CTS-XHP (as in, adjust the alloy at all outside of its spec), it would be very ill advised unless they lucked out and had Larrin give them a tip. Several people XRFed the steel, including a sawmill creek member, and described it as CTS-XHP. I think disclosing that would’ve been a boast – it’s expensive, but to the average person who is getting into the hobby with white-collar pockets and no collar knowledge, maybe thinking it’s exclusive is more valuable. To have something that’s not easy to get. Well, CTS-XHP itself isn’t easy to get – Carpenter just never really found a market for it that wasn’t better served by something else.

I guess we all pay our entry fee into this. I did. I bought enormous amounts of stupid stuff, and other than once in a while feeling a little guilty about spending money that was of no consequence to me to spend at the time.

You shouldn’t feel guilty if you mention to other people that the world of influencers really doesn’t have anything to do with making, but you’re not obligated either. I don’t think any of the influencers deserve deference – the persona of providing information doesn’t hold water and you’re not being rude by asking influencers to disclose what they’re paid for and how much. Ask them what the affiliate commission is for everything they sell. It might create a little bit of real grass growing in the world of astroturf if enough people start asking and the volume of requests gets to be too large to just moderate out every comment.

You’re never going to do anything that will change the course of real makers, so you can ignore anyone who thinks you’re “damaging the community”.

Of course in all of this, i could be all wet about all of it. Could I be all wrong? Sure, I could be wrong about Wright, I could be wrong about Animal Trades – we’re left to suppose things because there’s no disclosure. Sometimes. There can be misleading disclosure. In my opinion this would be something like Stumpy Numbs talking about a product, claiming the video isn’t sponsored by it, collecting affiliate token revenue for the item and then having a different sponsor at the end. Sometimes this switcheroo is done so that the affiliate commission is generated by someone that the influencer might like as a sponsor or that has sponsored something else, just not that video. What would clear it up? Disclosure by influencers – but that does require diligence from all of us. If you ask Wright about something used as filler to fit around the affiliate stuff, make sure the answer is for everything, not for the filler.

Wright is interchangeable with a gaggle of anyone here, just used as the example because people quoted his opinion on chisels and blades doing something material for a maker. My experience? They don’t, but peddling that narrative wouldn’t provide much financial incentive, and leads back into something the marks in the farm will tell you “if they didn’t get paid, we wouldn’t have the videos”. If they didn’t get paid, there would probably be fewer, they wouldn’t be high production quality, and you might learn something much better from them. When I quit youtube, it was for an array of reasons – but one of them was that the volume of content goes up and up, and the chance of learning something useful from it vs. learning at the bench went down. And Youtube got too aggressive believing you should either watch enormous ad numbers or pay for content that is generally just a carrier for advertising, or is veiled advertising itself.

I have personally left a lot of comments in videos about what the total take is or disclosure of revenue sources. You can guess what the response to them is. I’ve never received any answer to intent but for coming from one person. Rob Cosman, who politely answered the questions I asked. That’s far from making me consider patronizing his business or carrying water, just as rare as that kind of matter of fact response, and nicer than it really needed to be is unheard of.