When I started making planes – which I don’t do much of now – I bought a lot of wooden planes. I don’t remember the number as some were junk, and most were sold off, or cut up and thrown away, whatever was appropriate -but it was perhaps 20 planes. One thing that stood out to me was Ohio Tools planes could sometimes have good wood, but I’ve never had a single Ohio Tool iron I liked. Including one of their metal planes with a tapered iron. They’ve all been chippy, though it seems to vary from one to the next.

Fast forward to today, and I’ve made two rosewood planes in the last month – a jack and a coffin smoother – and I’m in the middle of making a coffin smoother out of gombeira, or “brazilian ebony” or Swartzia Panacoco. Whatever. Typical density at 12% MC is 1.2 for the wood and it’s unique in how it works. It does have a little bit of directional preference like oak does, and that has no effect on handles, but it may not be appropriate for a plane. We’ll see if it splits the abutments. The dry sample that I have has a specific gravity of 1.32%.

What better way to size it than to use the just-made smoother. That smoother in this case has a 125cr1 iron that came out of a 390F double temper at 66. It actually performed fine, and was still at 66 here, but I bumped the temper up 25 degrees and it’s at 65 where it will remain. Nothing you ever make won’t chip or roll on something, but it’s still annoying if you’re a maker and using your own tools if they chip at all. is the chip because it’s not good, or because you did something that will chip anything. You never really know.

So, the shape of this coffin smoother isn’t that interesting – it’s one that I copied from an Ohio Tool coffin smoother that I have that I like and even the iron looked decent. Like well enough made that it should have been difficult to heat treat it improperly given the rest of the effort. Heat treatment isn’t difficult to do on plain steels. I haven’t, however, had any experience with Ohio irons that has been in a class with any decent English iron, and it’s a head scratcher. I don’t mean just mediocre, I mean it always falls short of even that.

I didn’t buy the plane in question to use it, though. I bought it because it’s a decent layout that still leaves some tubby plane rear in your hand and I like that – it’s less hand stress to use it even though it’s not very pretty.

So I tested the iron (which I haven’t pictured here).

66 hardness. WTF. Maybe I’ve always been wrong – maybe it’s just undertempered, but before I waste time doing that, I knocked some of the edge off with a punch. It looks like these two pictures:

!!!!!!!!!!!!!!!

Given my recent iron at 66 and this one coming through at the same, I had to bust out the calibration block that came with the hardness tester to make sure the diamond hasn’t cracked off at the tip. Nope, it’s fine.

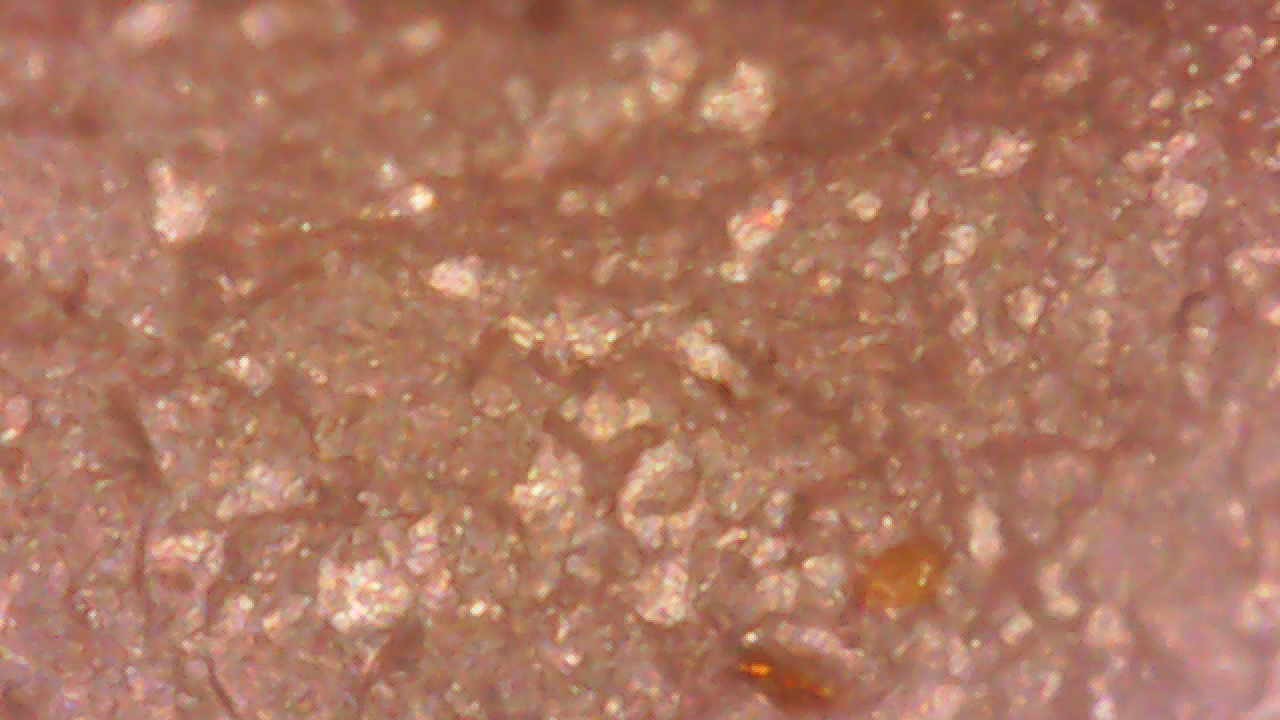

I doubt all Ohio Tool irons look this bad, but I have never seen anything like this before. it’s at 75x magnification, but those big flat facets probably are grain boundary defined. We shouldn’t be able to see much of anything.

Too, I used a tiny cross pein hammer (6 ounces?) and a punch to knock the edge off. That shouldn’t really be possible – the punch should just bounce off, but each strike of the hammer knocked a chunk out no problem. This iron has no chance. I have no idea what would’ve been going on when this was made – this is not difficult to avoid if it is just a heat issue. No clue what else it could be.

For a refresher, this is what my 125cr1 steel looks like punched.

Sometimes, it’s not quite as tight as this, but it’s always close. And always better than the grain in the Narex Richter was. That was also unacceptable but not remotely close to the scale of the Ohio Tool irons.

I would not buy anything made by Ohio Tools, especially trying to save a few pennies buying an iron to make a wooden plane. Spend the money on something from England. Mathieson, Ward, Early Marples, I. Sorby, or even consider eventually making your own.