When the power is out courtesy of a storm, and your neighbor’s generator starts to sputter from running out of fuel, and they’re not home to refill it.

I left work a little early yesterday just so I wouldn’t be walking through town as a somewhat nasty line of storms hit. It came sooner than expected, but I was already in the car. On the way into the neighborhood, before roads were closed and anyone did anything, I stopped at the corner and snapped this picture. If you look closely, you can see that there is a telephone pole down across the road.

The storm was quick, a couple of minutes. You don’t see poles laid over like that every day – and I guess in newer neighborhoods, you don’t see them at all. However, how many could there be. I had idealistic delusions that someone would be resetting the pole in the evening.

But, no – there are 2 more laid over up the road in this same neighborhood – but past this one. I didn’t venture out to get a look at them. And this morning, looking for an update from the power company, one of three here, but the largest…….there are 22,000 individual locations where wires are on the road, a telephone pole is laid over on the road or both. That’s a lot of work, so needless to say here about one day later by the clock’s ticking, the picture looks just like this except for caution tape and no rain.

I would normally make a joke about working by hand and not needing electricity, but I still have work and deadlines like anyone else, so I have been living by a cycling generator, laptop and wireless hotspot and checking food to see if anything has unfrozen in the on and off cycle.

My neighbor is a good guy – genuinely, but he prefers a scorched earth solution with the generator – run it as much as possible. We are downwind from him on postage stamp lots and his generator is at least three times as loud as mine. It sounds like one of those mobile worklights you hear when you drive past jobsites.

It just ran out, and I feel like the off grid standard of living just went up.

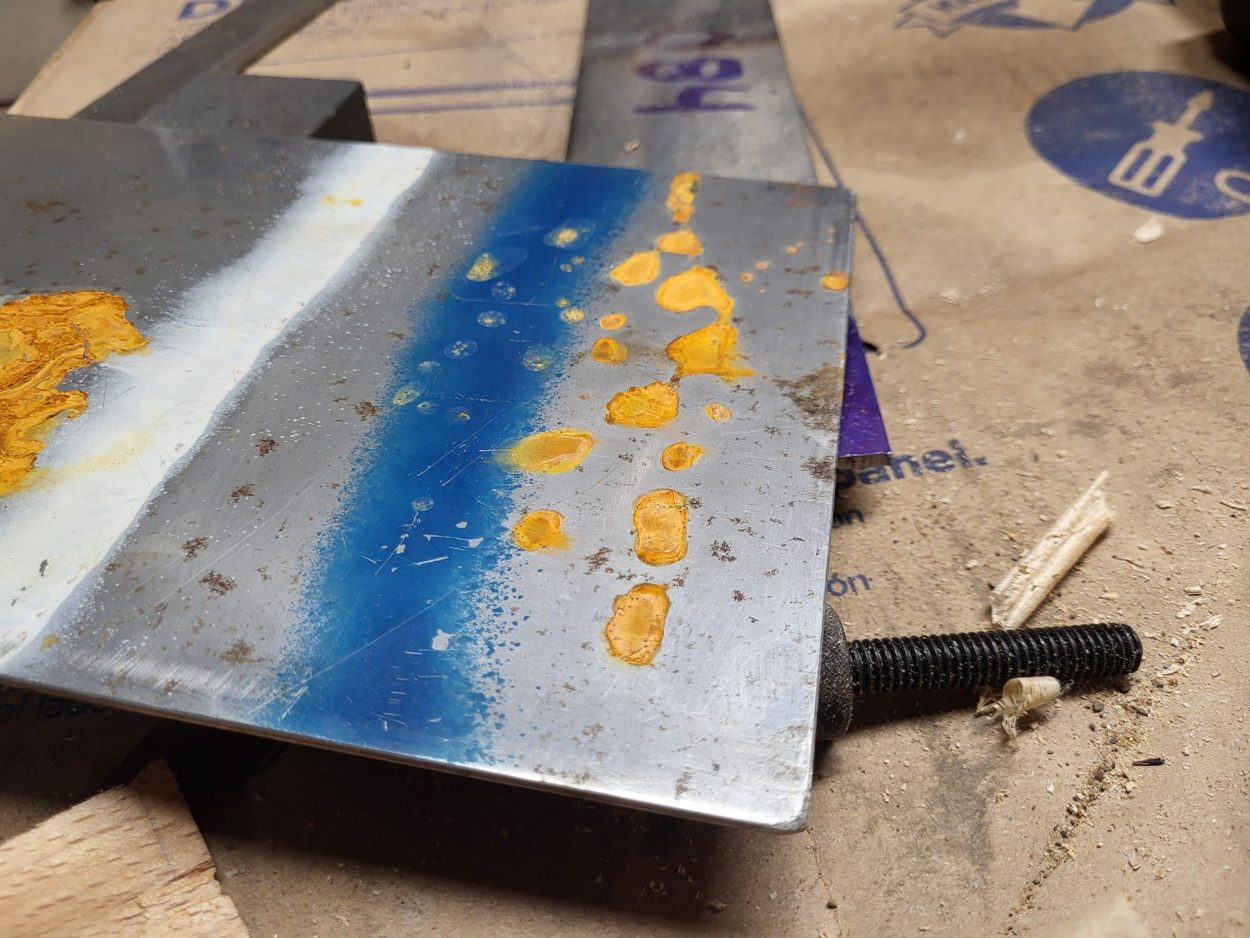

But, anyway….that leaves me with one thing I can do, which is to figure out whether or not my tarted up plane will be tarted up like high class lady of the night, or not as high. In a more serious discussion, it leads to making decisions on finishes on tools.

So far, this is all varnish except for tung oil and wax on the underside. If i’m being honest, doing this is a waste of time, and in the past, I’d have done this with shellac and then wax, or oil, shellac and wax, or oil and wax. The key thing here is what am I going to do to touch up the finish? It’ll be shellac or wax or both. This is more out of curiosity of how this will work. But rather than leave this in varnish, it could get a transition coat of shellac and then wax. Why? The varnish has japan drier in it, but it will cure over time. Can I wait that long? Probably not- when it is reasonably firm, I’ll go over it with shellac and mineral oil, and then carnauba wax. The carnauba wax is in turpentine – you really can’t rush turpentine to varnish that’s solved in…..turpentine, or you’ll soften it and then the wax will really look bad.

But you can put a transition of shellac on the plane and the wax solvent seems to cause no issue. and realistically as this starts to take wear or dirt, I want to deal with it using wax, so there’s no great reason to wait. It has a zero chance of remaining undamaged.

I like the tone of the varnish, and the photo probably looks like it’s staged outside, but again, it’s distraction from storm clean up, a break at lunch and then realizing, it’ll be tomorrow morning that I can handle the plane if I don’t put it outside in warmer air with at least indirect UV. Natural light is much more kind to the tone than the garish super bright white LED lighting in my shop. Those lights really do kind of bother me – they are so cold tempered with their color that you can’t get a good sense of what color things will actually be. I’ll bet they have lights like those in morgues and cosmetic research facilities where they test on animals.

All of my earlier planes out of impatience (again!!) were finished with linseed oil and wax. by earlier, I mean like of the era when I made the youtube videos about planes – 2013 to 2015 or so. Long time ago now. Things I didn’t have the patience for back then – really dialing in the bedding of the irons in the planes or adjusting the more human irons than the current surface ground generation of things so that they were really dead nuts, I have patience for now.

But I don’t yet have patience to do the planes in varnish end to end without giving the finish its more permanent look of carnauba. It’ll dull things some, but it’ll make it much easier to touch up filth or scratches or whatever.

Between this plane and the next one, I can think about things that will make the plane more visually interesting the same way a 1968 les paul custom is more interesting than a CNC made flat topped hamer guitar….and not necessarily the way a puffy shirt is different from a flat tshirt.

My neighbor just restarted his generator. He’s a great guy, but I wish he had a smaller gas can or less reliable generator.