A chemist sent me an email pondering whether tung oil cloudiness is in the oil, or if it’s a matter of texture, or surface geography. I was curious, too, as I have had one anomalous test piece on wood cure with glossiness using raw tung oil and japan drier, but I’ve never seen the same thing since.

To get pictures, I bought two glass plates at the dollar store and put a coat of tung on them, and linseed on another, and a 50/50 mix of washed Swedish linseed oil on a third spot. The linseed oil dried clear and was unspectacular, and the 50/50 mix was close, so i have no pictures of them. The light passes right through and there’s not much to see.

It turns out the frosting is typographical. If you build tung on a surface, you can wet sand it to a gloss, and/or top coat it with something that levels and it will be functionally clear.

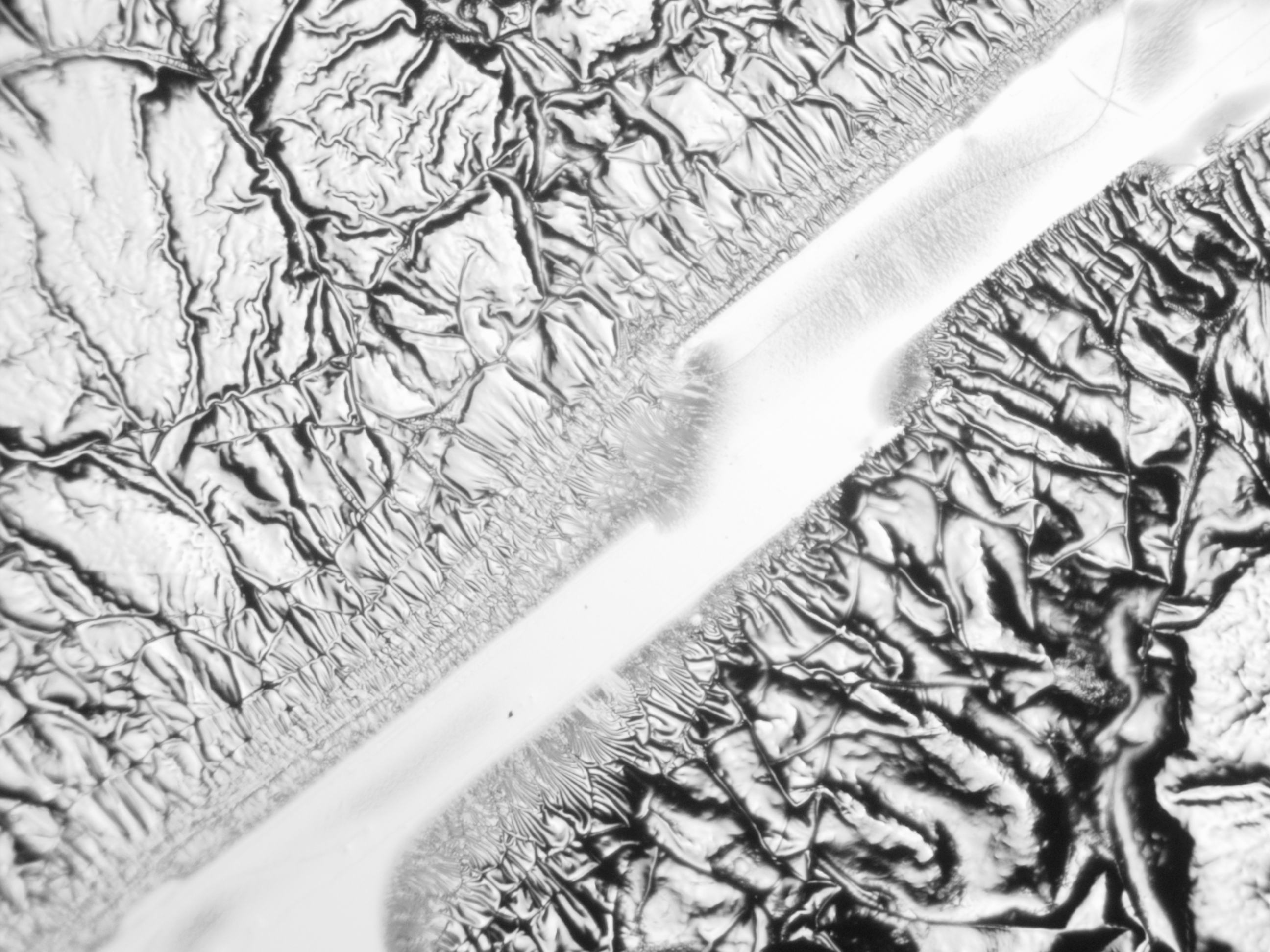

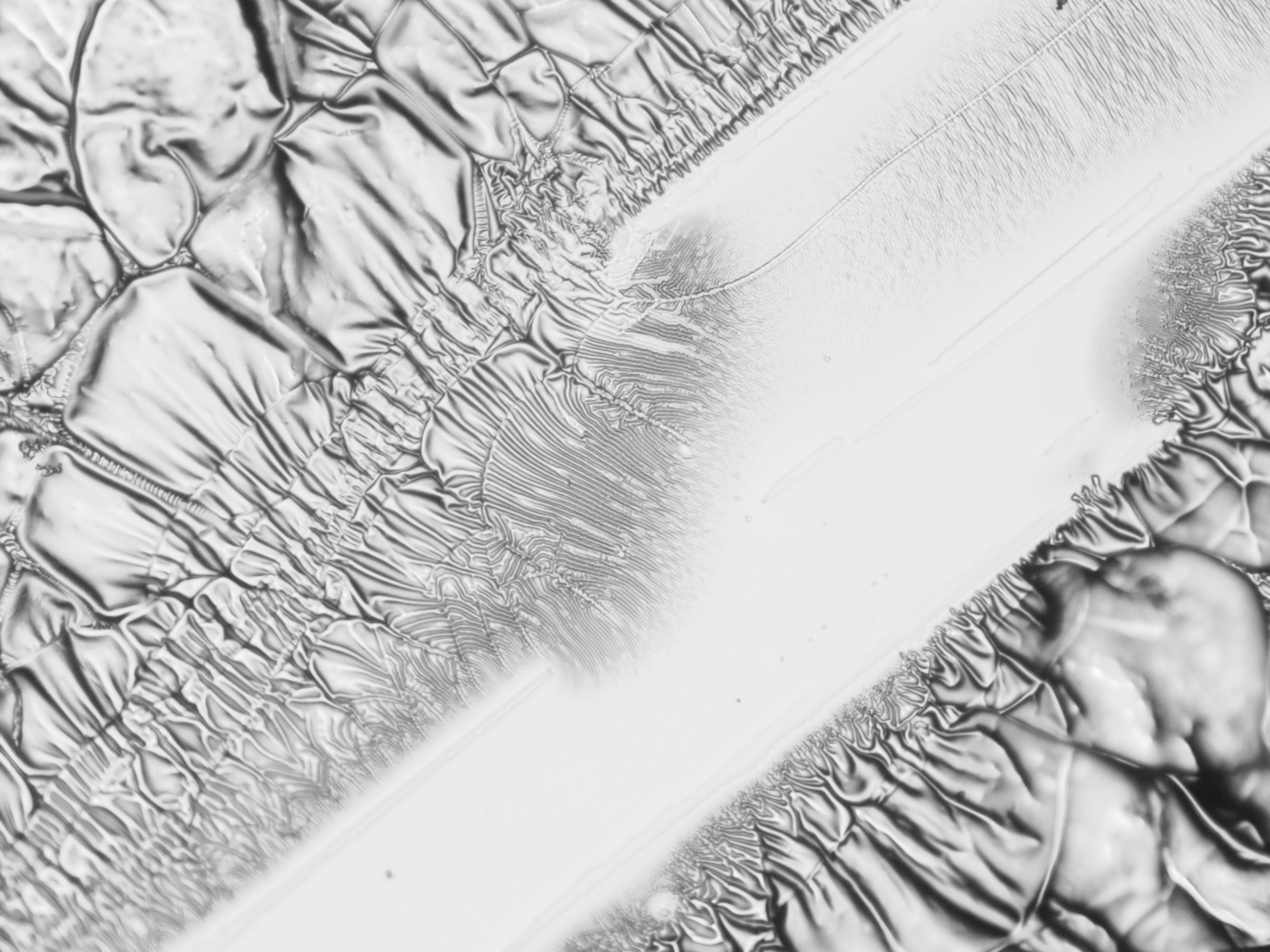

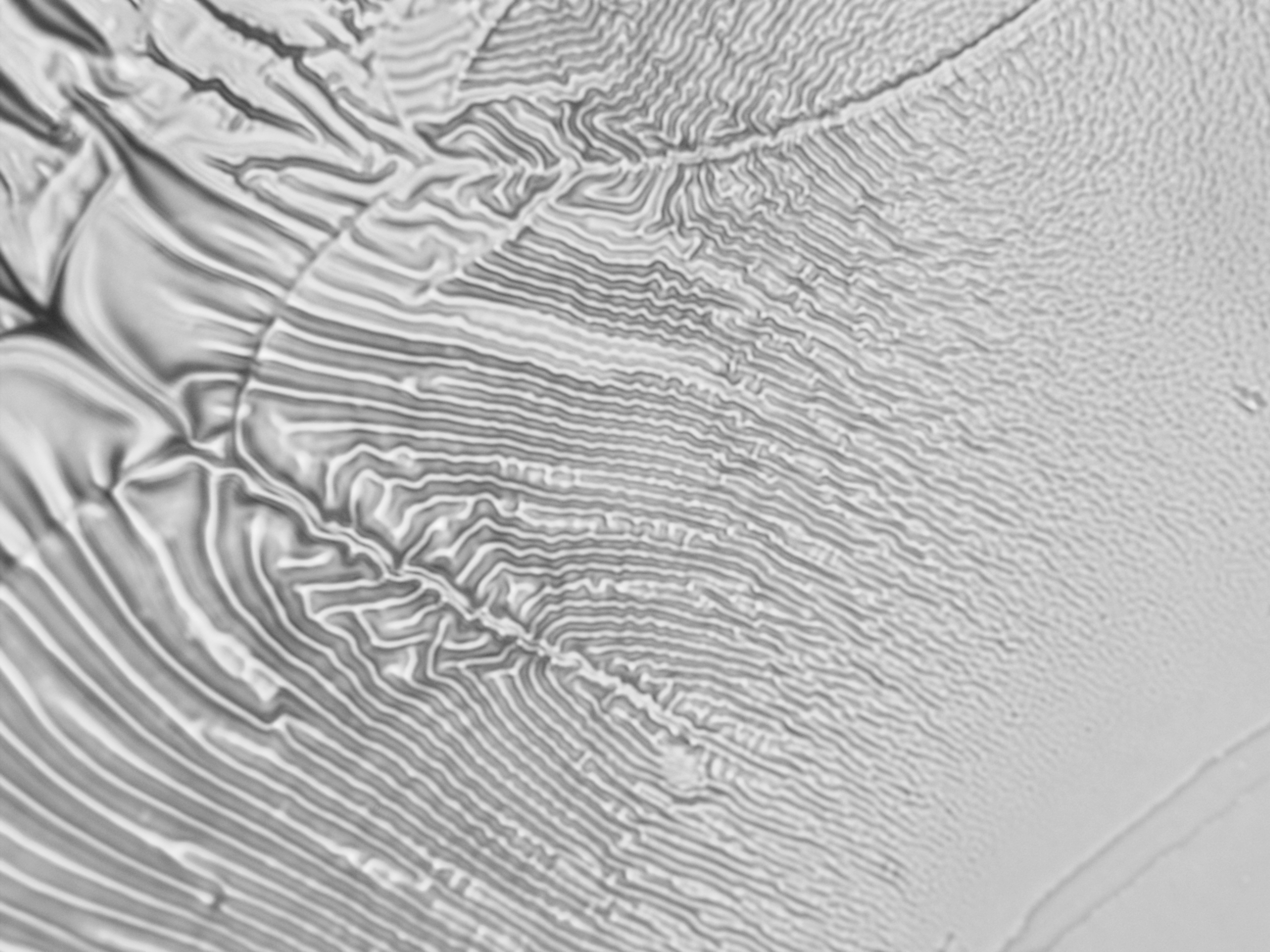

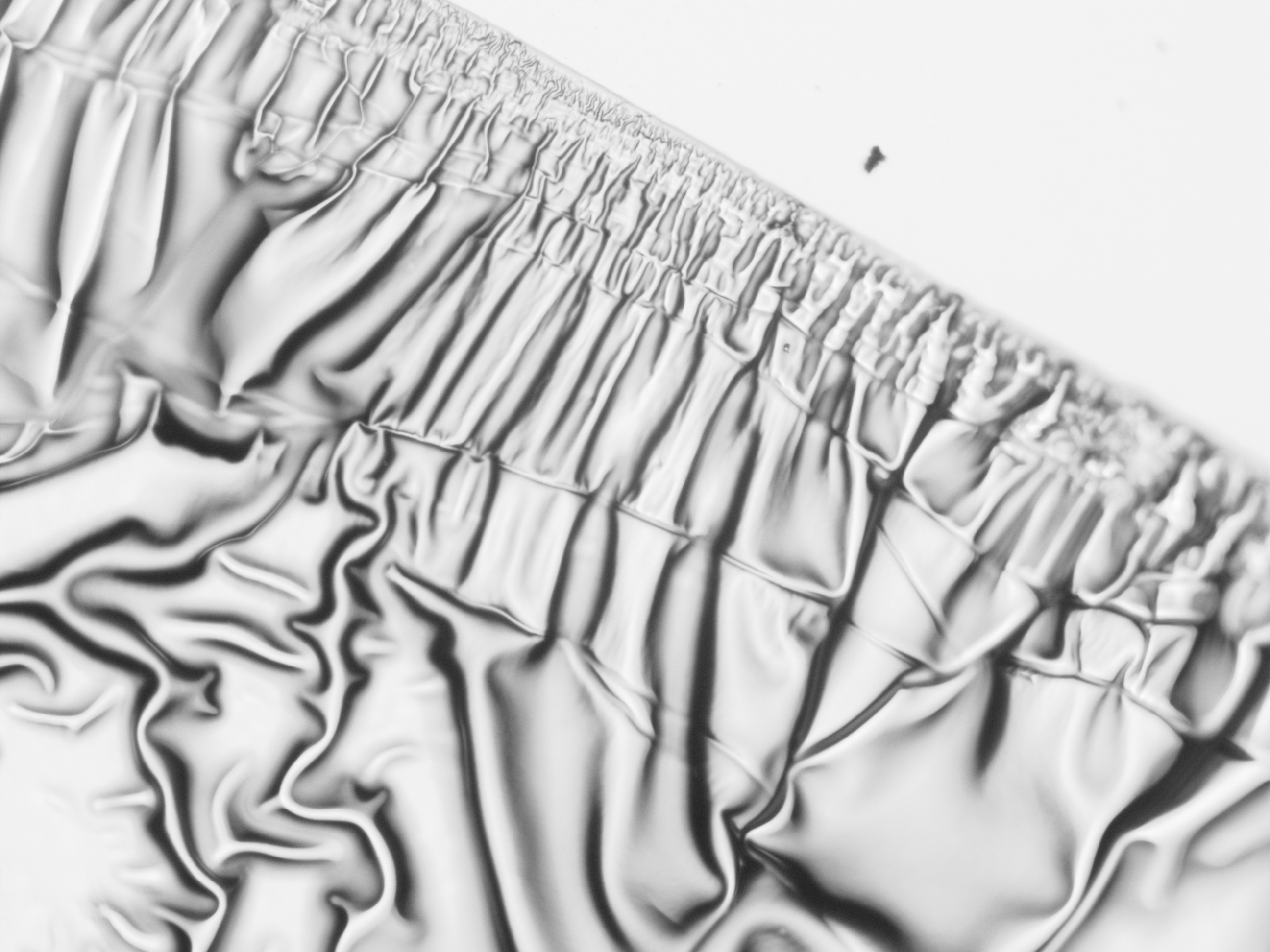

You might find the tung oil pictures interesting in the same way a close up picture of an insect eye is interesting.

Below is a group of three pictures at different magnification, but the same spot.

With each is a URL to click to get a much larger picture if you’d like to look at details.

As the finish gets thinner, the topography is lower. The density of tung when cured changes more from raw oil than does linseed. It’s a curious question as to whether it expands some first before curing, as the top layer increases in surface area without the finish pulling away from edges, so it’s not similar to the effect of wrinkling paper. Changing circumstances of drying temp and thickness layers affects how coarse the frost topography is.

Various other pictures follow. But before them, one side piece of knowledge here. I wanted to water test all three oils or mixes. Turns out, even the linseed oil will allow standing water on it to dry over an extended period, and any mineral scale can be wiped off without affecting the oil film at all. I’m not going to test cheap hardware store oils to see if they degloss, but it was a surprise to see how well linseed oil with 1% Japan drier does against water, contrary to the myth that it performs poorly against moisture.

Rosin and linseed varnish, on the other hand, is ruined quickly by any water that is allowed to lay on it, and is thus a good reason to use tung for rosin resined varnish instead of linseed.

Anyway, the pictures:

Interesting! I have been toying with the idea of combining raw tung oil (also curious about washing tung) with linseed oil for outdoor use. Problem is that Selders refined linseed oil is really good and convienient for outdoor use. Also curious about the long tung oil and if it is similar to Le Tonkinois varnish, which I think is linseed oil + tung oil + resin.

I know that some window restoration guys were really in to tung oil in the 90’s over here. Apparently it preserved wood from rot better in a test compared to linseed oil where treated wooden stakes had been put in to a compost for a couple of years. Which in all honesty isn’t really a truthful test for woodwork anywhere on a building, where no wooden parts should ever be in the moisture levels or microbial activity of a compost…

Selders also claim some very good resultat in similar tests with their refined oil, which in my experience is very good for wood preservation and dries very quickly despite not containing any driers.

I would like to compare tung to linseed oil myself though. I have been washing and refining linseed oil and I am planning to see how my stuff compares for outside use to a bunch of different commercial products. I am also a bit curious to see if impregnating a piece of wood with raw linseed oil and letting it cure and polymerize for a couple of months before putting it outside changes anything.

Anyways good to see you posting again. For me at least, with family and work it is hard to find time to chase interests, and it is nice to see that you also take time to post your findings.

LikeLiked by 1 person

I was wondering if you could “remediate” that wrinkling with addition of zinc, like zinc resinate (rosinate) in the early 20th century literature on driers zinc is considered as a through drier and often advised to be used with cobalt to prevent wrinkling. What thaose books say is wrinkling occur when the top layer polymerize while the layer below remains fluid.

LikeLiked by 1 person

Yes on the remediation. Zinc resinate addition does make the tung oil a varnish, though. And that’s definitely one way to get it to dry clear. I have not made a varnish longer than 1 to 3.5 or so yet, though. As in, the resin is 1 part to 3.5 of oil. That results in a finish that’s clear. The higher the resin component, the more clear it is, but we are in orders of magnitude talking about “how clear is the clear glass” here vs. the tung being frosted.

I’m using a drying agent with tung that has zinc, cobalt and manganese in it, which is sort of a trio intended to catalyze faster, but to allow oxygen pass-through on the surface so that it doesn’t wrinkle like this. For tung, this just seems to be an occurrence, and probably due to more than just surface drying as we’d see in other finishes that crows foot.

For whatever reason, adding resin with drier, or resinate where the drier is in the resin, works. The trick to find in this case is would the zinc work on its own without adding rosin? From what I see, the answer is no. I haven’t found anything yet that describes how to get tung to dry clear, but from a functional standpoint, if a long oil varnish with some resin is waterproof when tung is the oil, and you can put drier in it, is there a practical need to have tung only with no resin. I think the answer is no – long oil varnishes wipe on with more of an oil feel, so as much fun as it would be to try to get the tung oil alone to dry clear to create “a first” without just resorting to building it up and wet sanding off the top layer to get rid of the wrinkles, it makes far more sense to just make a varnish that’s long oil, as you’re describing. It’s really easy to make a tung/rosin varnish. The oil does not have to be run or broken first, just warmed a little and tossed in with hot rosin and you have a varnish.

LikeLike

It always goes back to varnish! BTW your varnish looks amazing! I was wondering where you get the oil these days? The standard BLO from the store is horrible in varnish, after-tack a week from applying!

LikeLike