Starts at page 135 – “To Face a Piece of Stuff”, and is one of the more interesting sections in how little it provides. Which is a clue to you that planing a surface flat is not always going to be a system of the same steps. It’s more of a feel thing.

Toss out most of the board facing exercises you see on youtube intended for beginners. Planing X’s or whatever, that’s not reality when you dimension by hand. It’s just some attempt to get beginners to feel like they have a do-all method.

Nicholson describes a flat surface as one made of straight lines, which we would think of as a plane, of course. His point is that you can draw a straight line from one point to another and then draw another line and both would be in the same plane. And that winding sticks placed anywhere in pairs would be viewable across the top with no wind.

I’m assuming that you understand wind/twist, and so on. If not, you can look them up.

Instead of a generalized method, Nicholson suggests that you should see what the board is and then address it. This makes sense. Recall some of the prior discussion of the use of planes, that the work is with the grain and not across it. We won’t be taking every board, going across it for no reason and then planing an “X” pattern on the board to guarantee it’s flat, we’ll generally be planing through the wood and removing the impediments to the ideal above about everything being in a plane.

In the example of a board with wind (twisted), there will be two corners higher than the others. To deal with them, we just plane the high parts. Not through the entire board, but rather deal with the corners that are high. I don’t recall if we’ve discussed the cap iron yet, but assume you can plane the board in any direction. You’ll plane whatever is easiest, but you don’t need to worry about being unable to plane in one direction or another.

Here’s my tip at this point – you may be thinking of planing as if it’s going to be like taking a strong jog and you’re just cranking. That may be the case if the board has large sections to work, but it may also be the case that the most important thing is that you do enough and not too much. If thickness needs removing, you’ll have a chance to do that once the board is flatter and you can work in rhythm.

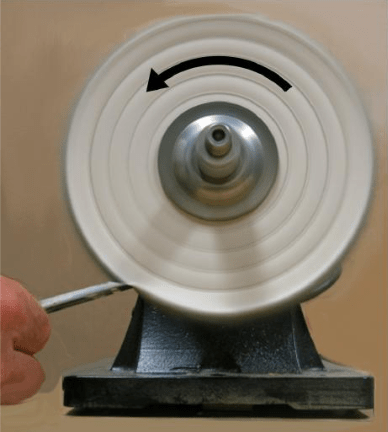

This kind of work is no place for a scrub plane, it’s jack plane work or in worse wood (runout) or better wood (already close to flat), it may be try plane work to start with. The try plane is a strange concept if you’re of the jack/jointer/smoother power tool background type. The try plane works more like half jointer, half fore. It’s not set for a rank cut, but it’s also not going to take tissue paper shavings. The jack plane is set to cut strongly, somewhat rank, but it’s not going to be set so that it’s tearing chunks out of boards or breaking off corners. If you use something like a “scrub” plane and you set a wooden jack a little bit finer and then measure the weight of wood planed, you’ll find the jack plane to equal the scrub pretty easily, but the work left behind will be much closer to flat and it will be ready for the try plane.

In Nicholson’s example of a board with wind, the jack is doing the work and at some point, the wind and any other high spots are generally gone and the board is in plane and can be moved to the try plane.

That’s it, there’s one example. Not one for cup, one for twist, one for boards with knots. It’s assumed that you will be able to plane wood competently. If you’re just starting out, this may not be a given, but it’s something to work toward – that you can choose a section – let’s say a high corner, and plane with it (center of the board off the end) or start with the high corner near you and start the cut and plane into it.

At the end of this short section, once the jack plane has gotten the board finished, Nicholson makes reference removing the jack plane ridges with the try plane, but then checking work to be certain you are keeping a true surface true.

This is minimal in words, but it’s loaded with things of “reality references” to me from learning to plane in a vacuum (self taught), but not wanting to resort to machine planing without the case being a project that’s just undesirable in the first place or with absolute trash wood.

First, it’s clear that you should shoot for flat with the jack plane, which is antithetical to the oft-given advice that the jointer is what makes wood flat. It isn’t, though it can do that, of course, you’re wasting your time if you’re still jacking wood away only to get the jointer in position to start removing wood to get it flat. You should have your stock flat and plane as much of what you need to do as possible with the jack plane. It’s easier to push not necessarily in pushing force, but it’s lighter, and if you have a 17 inch jack plane, it’s long enough with skilled eyes and hands to make a fairly flat surface. You will appreciate that you’ve done this when you get to the try plane and it’s quickly getting into continuous cuts vs skimming across various bits of wood for a long time and then still planing a piece that’s left with twist or an end falling off out of plane.

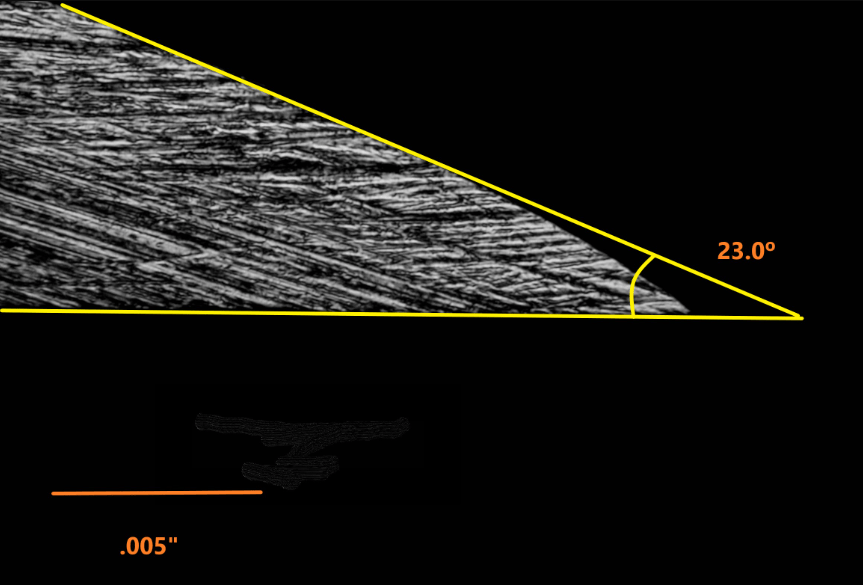

Second, it’s not said explicitly, but there is an assumption that you can plane a flat surface and keep it flat. There’s a whole host of things that goes into this, but it’s definitely the case that you should or you will get to the point that you can plane a board or panel end to end with a try plane, not have the plane in and out of the cut due to tearout and keep a panel relatively flat as you’re working the surface into the level of fineness that it needs to be to put the stock aside to be sized or smoothed. This state of removing layers does not exist without the cap iron or a very steep angle single iron plane. If you try to do this whole exercise with a steep angle single iron plane, you won’t do it for long.

My tip to you is to expect to get to this type of planing sooner rather than later so that your strokes with the plane are in the direction of the wood and will mimic what your final through planing will be. Work will progress and be completed much later without wasting time trying to get cross-planed wood or diagonally planed wood to cut continuously with through shavings. The try plane will communicate whether or not the “piece of stuff” is flat, and you can turn the plane askew a little bit each way to make sure that the work is not falling off to one side unevenly. Check things by eye and refine your eye and leave checking with winding sticks and a straight edge to when you either need a break or you’re doing a final look.

And appreciate that you have this discretion to plane off the high stuff with shavings in the length of the board in most cases, rather than just employing one same method over and over. You’ll find that this type of flattening can be very sparing of a board that would not meet thickness needs if run across a power jointer until flat.

So, does this mean that you’re never going to traverse a panel? No, there will be cases where you have panels that are short and relatively fat and traversing them or planing them diagonally is a relief to your back. With time under you’re belt, you’ll figure out what’s easiest. In my estimation from experience, though, planing directly across something over and over is uncommon unless the quality of wood is terrible and you’re *thicknessing* after one side is already flat.

Develop that feel, though – the feel when the plane is communicating that it stays in a long flat cut, and let it tell you what’s high and what’s low in the process of work so that you are working and adjusting continuously, and not stopping and checking with sticks and making pencil marks or whatever else.

Are there other things unsaid here? Sure, like if a board seems to be a bunch of high and low bits on both sides, which side do you start with? It may be necessary to plane the opposite side of a board to knock off some high spots just to be able to face the side you want to. If you have a board that’s got a lot of cupping, it’s helpful to plane the convex side first. If you have a board that has so much twist that it doesn’t want to stay flat, constrain it somewhere that’s not in your way, and that won’t bend the board – but so that you can plane the high spot without the board seesawing up and down. You’ll figure those things out pretty quickly. And that’s probably why this section is brief in the book.