Last year or the year before, I took pictures of the scratch patterns from a lot of sharpening stones. Most of them, I still have, but I have the pictures nonetheless and more can be added.

At the time, I posted on a woodworking forum a “sharpening stone omnibus” or some such thing. It didn’t generate that much discussion, but when I’m exploring, it’s never a matter of seeking adulation, so that’s not a problem. What I’d hoped (And did nothing to facilitate) was some visual record of what sharpening methods do as there’s nearly no correlation between cost of sharpening method and speed or results (fineness). At the time, I showed that with psa 80 grit (as a grinder) and a throw-away fine india stone and a white buffing stick that I bought for $0.99 off of the Sears clearance rack was finer and just as fast as anything. The india stone came in a group, but if you had to price it, you could claim that it was a dollar (what I wanted from the bag of stones was some natural stones and those were already a bargain).

So, more in the spirit of showing what natural stones do, and providing information and maybe preventing expensive unnecessary purchases, I am going to gradually repost and index the results here.

There are a lot of debates about what stones are fast for fineness, or so and and so forth (for example, on a razor forum that I once visited, the strong notion existed that only the naniwa chosera mid stones were worth having unless you were short on money. This is, of course, not true, and the microscope will show a razor edge before and after a shave). I’m generally avoiding the middle honing and the grinding, though – it’s always the search for a magic fine stone where people dump huge amounts of money.

And if that’s what you want to do, that’s fine, but you’ll be able to see what you’re getting.

What I found in general is that when you have a fine even matrix somewhere around 1 micron, then all but tiny scratches at the very edge of a bevel disappear. There is a whole lot out there that’s cheap and strong cutting that’s in that fineness, unlike 75 years ago. And there is no natural stone that will outdo synthetic grits if you want to chase fineness and edge longevity in push cutting (planing). It’s a hard truth, as I’ve spent as much as $700 or a little more on a single sharpening stone (not often) and that amount or a little less may be very typical for rare natural stones or the more highly marked up Japanese stones. Those rare stones are wonderful to use – and the more stones you’ve been exposed to, the more you start to notice the wonderful different feels and smells of various natural stones, and the quality (as in, properties other than outright sharpness) of the edges they give, and the aesthetics of a laminated edge that they can be manipulated to perfect. But for outright blistering sharp, you can get that for less than it costs for a nice lunch.

Unlike most claims of woo, I have the microscope pictures to prove it, and at one point in a group of tests planing tens and tens of thousands of feet of wood and taking edge pictures, I have the longevity data to settle the argument about whether or not some special transformation of edges happens under certain natural stones. Unfortunately, it doesn’t. Any burnishing or adhesion that’s done to an edge is something worn off quickly when planing wood.

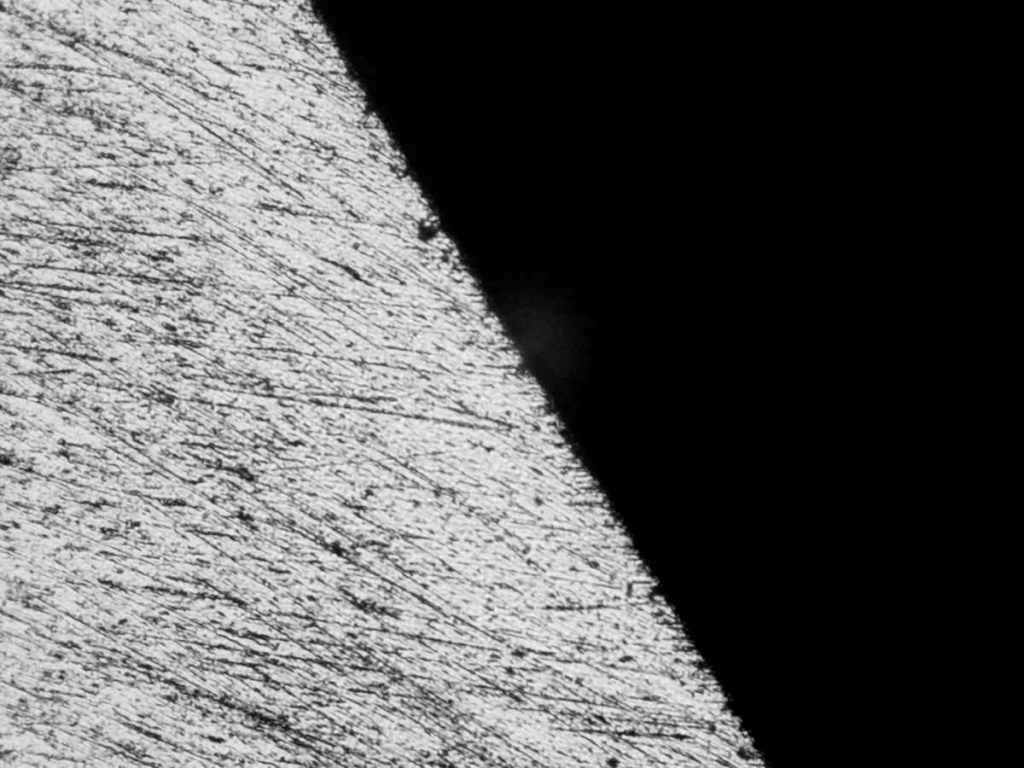

Just as a teaser – below are two pictures – one is an edge on a slurried very very expensive very fine and hard japanese suita. The other is an edge created more quickly with a washita and autosol compound on wood. You can guess which is which (and while the pictures may change slightly with technique or no slurry, etc, and lighter pressure), the overall theme doesn’t change.

What you’re looking at is the backs of two plane irons photographed under a metallurgical scope at 150x magnification. The length of the edge is around 2 hundredths of an inch. The only thing that really matters is the edge and a couple of thousandths behind it – basically how even the line is dividing light from dark.

The little black bits that are irregular are just dirt or fibers from clothes or a rag after cleaning an edge – I didn’t always get everything cleaned off completely, and doing so is actually fairly difficult as the lightest amount of oil will look like bubbles all over the magnified surface.