I’ve been pondering what to write about the conclusion of the very difficult to sit through and interpret info in the videos, along with the accompanying text. So, this post is sort of an intermission but also stating of a conclusion that I think is worth noting, and I’ll explain why below.

When I’m testing something, I hope to see something definitive or dominant. Dominant is a game theory strategy to me, because it’s one of the few classes I remember from college. A dominant strategy in a game is one where you will prevail regardless of how well your opponent plays, at least as long as you play to the strategy. Tic Tac Toe, for example, does not have a dominant strategy between two capable players. That was literally the first assignment in game theory – on paper (1997, for anyone young) – draw out all tic tac toe variations to find a winning strategy. I drew all of them – it was insane. I found no winning strategy and was really pissed figuring I’d missed it, because I struggle with basic executive function things and at some point in my life, it will burn me. I am pretty good at solving problems and contributing when someone else does the routine stuff, and then at least when I’m being paid, communicating what I solved and what’s important. Free writing like this, not so much.

Chisels aren’t tic-tac-toe, but I know the things that make for a chisel I don’t like. I also know what to do with any decent chisel such that I cannot sit here and tell you, for example, that I think the Richter has slightly enlarged grain, so you shouldn’t buy one. First of all, I’d have to buy a bunch of them to see if they all look the same. I’m not going to do that. Second, I know how to address minor issues with chisels at least several different ways. When I took the 52100 chisel of my own make and then the Richter, which fared poorly in the first test – noticeably worse than anything else, and honed a bevel of about 33 degrees on the chisel, it held up fine in what’s heavier work than most people would do (30 ounce mallet, red oak, 1/8″ bits malleted off). What’s to conclude? I could buff the chisel a little more without ever testing any of this and probably be pretty happy with it in use.

Nothing in this test showed up out right defective or out of spec to any significant degree, so the test is a failure of sorts, except to provide that information, which in a sense is a success. If you see the next Wright doing a test with some kind of string device and a fixed set of parameters, think about what I mentioned about the Ricther. Pushed to the point where all chisels damage, it takes a lot more damage. If that’s the only piece of data you get, you’ll think it’s brittle. It took exactly one attempt with a microbevel to get it to hold up fine. Both chisels held up so well that other than getting through wood a little more slowly, the lesson in the setup is 10 times more valuable than the test.

And something I know from experience, but didn’t have to deal with there by choice – a chisel that grinds slowly or hones slowly is a nuisance. A chisel that is too soft to hold a thin enough edge to not really be a lot of physical work in hardwoods is a real nuisance. We didn’t have either of those, so all of these chisels are fine.

The Zen Wu chisel is heat treated properly, it’s right around its hardness spec and the curiosity from the start here was to find out if someone would make an affordable file steel chisel. In relative terms, it’s that. The surprise is then that someone would make a chisel that’s probably better for $10 per, just with an abysmal handle, and I can’t help but say it, the Wu chisel appears to be a copy of something made in the west by LV and I just don’t like that. It doesn’t matter if it’s Woodpeckers or LV, I don’t like copying things even if it’s half hearted, unless they’re kind of public domain. copy a Ward chisel or an 1880 marples? As long as they’re not marked fraudulently, no problem. But to lift the design from LV for the most part? It stinks of either being tone deaf, or intentionally trying to shave some from LV’s coin via trade dress fouling.

I’ll still write a separate post with some aspects about each chisel, except I’ll leave mine out. They were there just as much for my own curiosity.

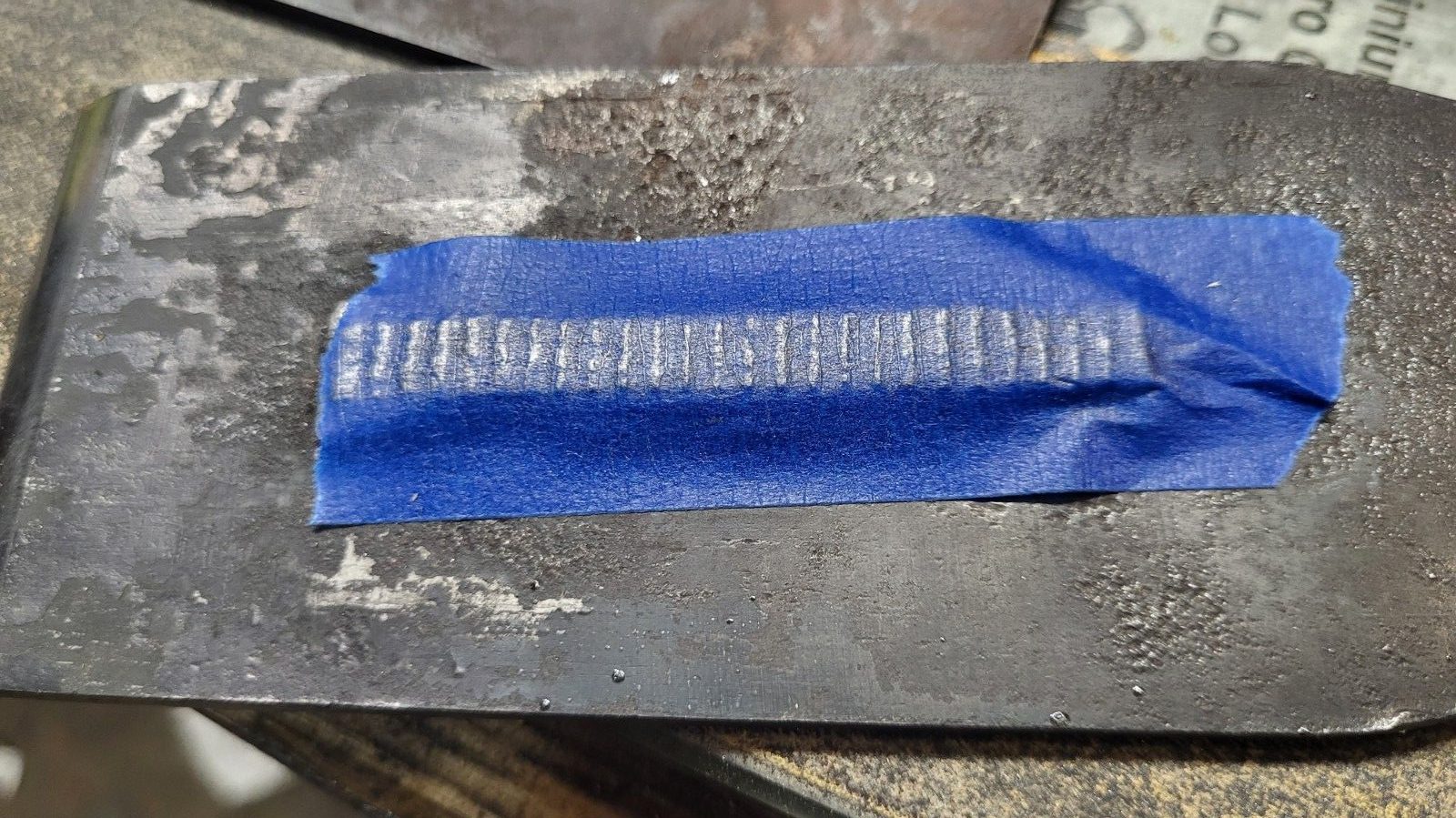

Lastly, before my conclusion – I thought it would be interesting to see if there is visible damage. There is. It’s harder to photo than it is to see it or feel it, but this is the scale of the damage we’re talking about from the pretty harsh looking damage in the videos.

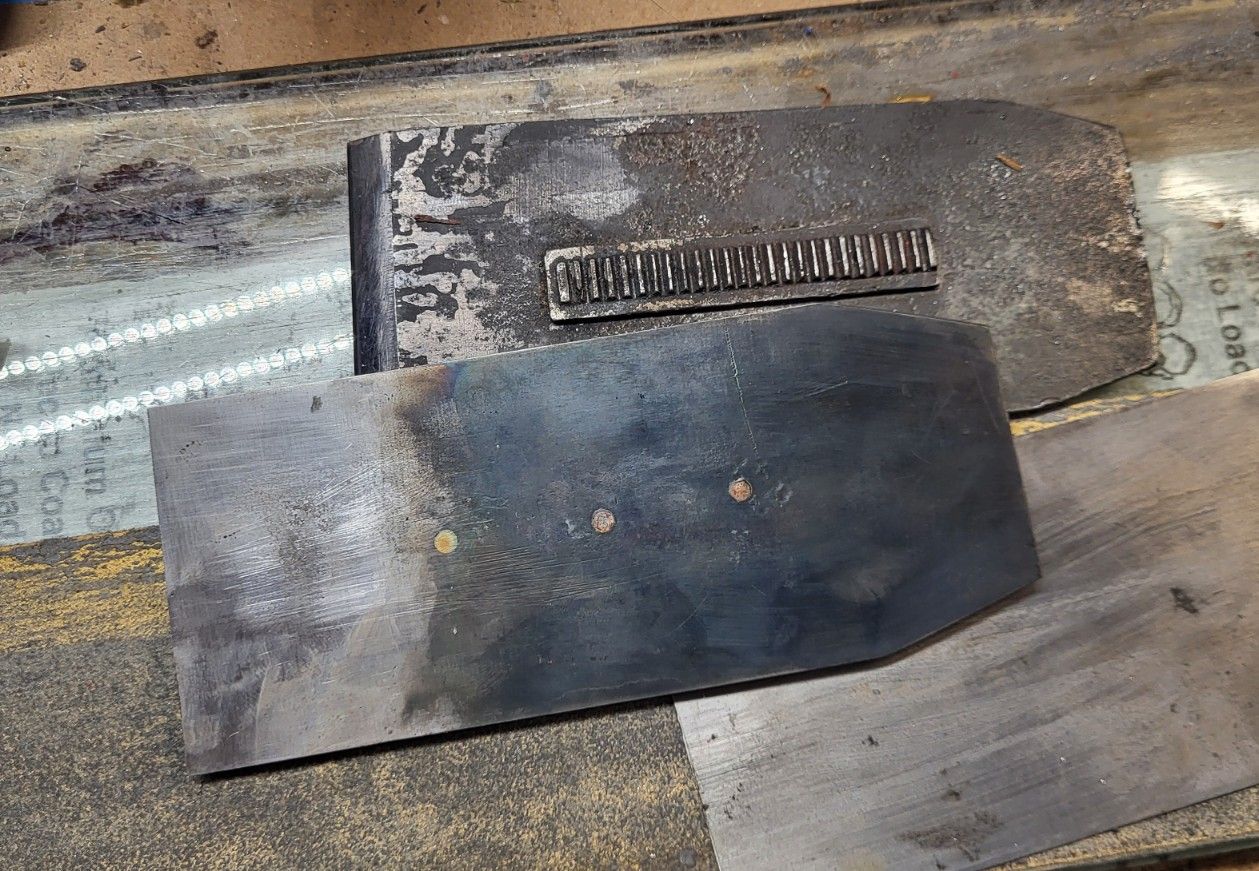

Top to bottom 1) 26c3, 2) Zenwoo, 3) Ward , 4) House 52100. The 26c3 has less damage in the video, again I think the chisel itself has a lot to do with that, from the thin harder to hit handle, to spring, and even to the fact that with the same passes across the buffer, it will allow more steel to be buffed off even than 52100 probably by 25%. It holds up well, but it was 10 or 20% slower in strikes to get through the wood. The others here were about the same.

52100 is weird looking – while the other chisels show a white line of deflection, the 52100 almost takes a polish at the edge. It always does this, and I have no idea why – the damage is there, but the edge turns dark like that. it’s not an indication that it did better, it just looks different.

The other interesting bit here is the third chisel from the top – the Ward – is somewhat soft on the top corner and if you look really closely, you can see that the edge is knocked back a bit. That is where the big foil showed up in the scrolling video. But it’s only a small part of the edge, and while it would be a completely obnoxious situation if the whole edge was like that, it had surprisingly little effect if more than just that corner was in the cut. What it did do was prevent me from placing the chisel by handle and getting it to “stick” at a spot just before malleting. Stick just means you place the chisel and it doesn’t move. That littel deflection was enough to cause that issue and is a good reminder to me to be patient when grinding the bevels of my own chisel. I think I sent someone a chisel like that (Steve) and maybe it was just at the very edge, but it’s not hard to avoid and every issue I’ve had with temper or poor heat treatment has been something done in haste.

Since the Ricther came the next day, I didn’t get it in the above picture, but did take another one later. The 100cr-v chinese chisels came after this and I have no such picture, but there wouldn’t be much to see. This is the original test picture of 52100 compared to the Ricther. There is finally enough to see here that you can see some areas of deformation get away from the edge line enough that you’d have to do a good bit of extra work to resharpen. So, you would just set the chisel up so this doesn’t happen – that was easily proved.

The Ricther, is, of course, the one on the bottom. And it looks like the angle I had to take the picture somewhat disproves my statement above about the black edge on 52100. the little holes are dents from the hardness tester. the fact that the 52100 chisel seems to have a zillion on it is both from testing the results with it and then from doing another hardness test a few times because I did nothing to record the earlier results. it’s a mule, so it doesn’t matter. When I make chisels for other people, I try to get the hardness tester denting on the top side of the bevel before finish grinding, and it’s generally gone then.

So, Here’s my Thoughts

You’ll never read a chisel test that will tell you much other than some subjective things, unless you see chisels that are 60 hardness or below. If you work in hardwoods, you’ll prefer something 62+ as long as it’s a steel with enough toughness.

The rest of the charts and string tests, etc, aren’t useful. They’ll distract perhaps from the things you really need to know, which is what form do you like? If you pinch blades, you won’t like German chisels and probably not English tang chisels. If you hold handles, you’ll probably like English chisels a lot, and the more plain handles styles at that. They may look common, but they just irritate less than other handles.

There’s no reward that I’m aware of in any case, no matter what the test is, to seek abrasion resistant chisels for cold work. So any test that tells you that you need something that’s abrasion resistant or high speed steel for bench work is operating on some premise that the setup of the test shows a difference you’ll never see in educated work with a chisel. But you’ll notice that those chisels are a pain, and if someone is sharpening in four minutes with a honing guide, their opinion on sharpening time or method is not yet mature. And you can ignore it.

The lack of success in this test just goes back to why I don’t test chisels much – I think there isn’t much good information in chisel tests other than hardness and alloying information. It doesn’t take much to provide that info.