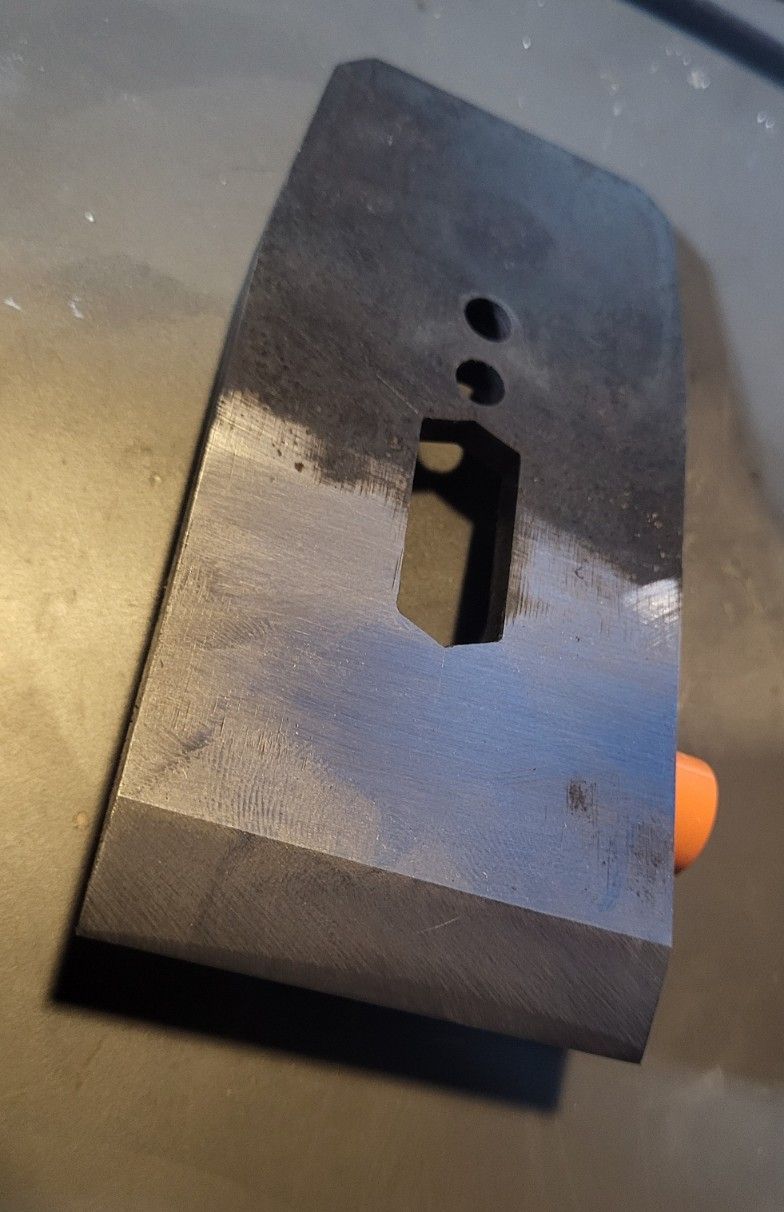

Would be dumb enough to make things like this? The iron on top that is.

I think this kind of stuff is interesting. It probably isn’t interesting enough to other people to do it and for some, maybe mental scorn about how it’s not “real woodworking”. Most of us aren’t doing “real woodworking”, though I’ve never been able to figure out what that is in the first place. Does it have to be real wood or can it be plywood but what you do is real? And who makes tools and calls it’s real woodworking – what is the rebuttal against? I don’t know. More on that at the end of this – but first on what I’ve devised, and it could be something different next time and so on. What I don’t want is to be bound to needing some kind of specific tooling or method to do this to a point of accuracy that’s at least as good as the iron that’s already there.

I’m thinking this is about a two hour project on top of that. A typical iron like a stanley replacement iron without machine tools is less than one.

I started with .187 bar stock. The decision to forge or shape comes up. If I had a flatter hammer and a second person who would hold it, this would’ve been faster to forge. I don’t, and my large anvil isn’t set up with space for someone to stand opposite – so there would be no time savings with that and it’s out. The subject iron here is about 0.16 or .155 and the far end of the taper is .085″. The raised area with teeth is a separate issue – you can’t see on the old iron but it’s got pins that go through to the front of the iron – they’re not flush peined, but I would assume they are affixed by being driven in and they obviously never came out.

Back to the stock. My favorite way to deal with something like this is a round contact wheel and a pair of calipers. And since it’s short, a one-time holder for the iron isn’t a bad idea, but that can come after the iron is cut out of bar stock and the ends have been beveled to set a visual stopping point.

This is what the one-off holder looks like:

What you see is a longer stick of cherry, and I took a picture after the fact, which may not be quite as helpful. the idea here is just a longer piece of throw away wood that’s a little less wide than the iron so that I can check the sides with a caliper. The screws are driven in close to the ends of the iron, but they are driven in far enough that they put lateral tension on the ends of the iron. There is no belt and suspenders thing that does more than that. The screws have to be below the level of the final article or they will get in the way of grinding.

This is then ground against the contact wheel for a variety of reasons, but among them are the fact that a belt grinder at high speed with a contact wheel is efficient, I can direct the dust and metal shavings toward a bowl with a vacuum hole at the bottom, and I can remove metal in just about any way from a point on the edge of the wheel to a line across, and rotate the iron with that line to lay it crossing prior passes. As long as you don’t grind the ends of the iron off in specific ways, you can literally use this method to make an exact replacement for an old wooden plane if you need to. In this case, it’s within a few thousandths of the original, which isn’t that accurate. The lower corners on the fat end (left) are not totally in plane, but they’re not far out and probably won’t need to be addressed, anyway.

the next step is to locate and install the toothed strip on the back of the iron for the plane’s adjuster to engage. I have the plane in another room that’s clean and dry and can test the result to make sure it will work. but you can envision a lot of difficult ways to make this strip and file it. The smartest for simplicity’s sake is not to machine the whole thing including the legs that go through the iron in one piece, but rather just take flat stock about the same thickness as the bottom to the top of the teeth – in this case .105″. That’s nearly identical to hot rolled unmachined 3/32nd stock.

What’s First?

This iron will need to be hardened and it has to be relatively flat, and then the adjuster fixture will be installed after. It would be possible to do all of this first and then just harden an inch of the iron or so. This plane belongs to Raffo – it would be a challenge to get Raffo to use an inch of the iron – that would take a long time, and there’s no guarantee the plane will be nice to use. This was Lie Nielsen’s philosophy with W1 irons long ago – challenging to harden to the slot in an industrial setting so only half of the iron’s usable length was hardened.

But I would really rather have the length up to the adjuster hardened and not just a little, and I’d like it flat. So it will get a typical routine here for irons – heat/thermally cycle, ramp up heat, quench at the top end and then plate the iron on the anvil under an aluminum plate for about 10 seconds. It’s uncommon for an iron to get away from that routine and not be pretty flat. Before adding the plating with thin irons, I would bow a few trying to both use no fixtures and also precut a little of the bevel to game the bowing of the back. if you have a bevel, the flat side will be hollow 19 times out of 20, but too much and it’s a wasted effort and getting too much hollow isn’t hard. So I shoot for flat now and cut the bevel in its entirely when the iron is hard.

I’ll make a small tool out of a board and a file to cut the rabbet on the stock next to the teeth and then pin the fixture to the iron with bronze brazing rods 1/8th in diameter and file the teeth in last. That will be done after the iron is hardened, so the hardening can go up to the point where the first pin will go in. Pictures never show taper well, but here’s an attempt, anyway:

I think it’ll turn out fine, and the sort of visual here so far aren’t the end – it’s a rough iron at this point and can be touched up after hardening both in grinding and lapping if desired, but also just for visuals. Lateral lines from sandpaper will be gone – they’re not exactly appealing.

if you’re wondering what’s wrong with the original iron – it’s not very hard. I don’t think it ever was and I attempted to reharden this iron in fast oil and it didn’t get appreciably hard. Rather than chance ruining it by quenching it in brine, it can be put aside – that can be done any time in the future if it’s desirable, but the bevel would need to be ground off and that length lost. Doesn’t seem optimal. I don’t commonly find defective irons among mainline tools, but finding auburn or ohio or below that the lower volume one offs that just don’t have very good irons is common. I tested a very pretty Ohio iron yesterday that was later make and is laminated and it’s a whopping 31 hardness (!!!). Hard to believe, and a second strike with the hardness tester showed the exact same result. Luckily, it was unused.

I’ll return with a finished post sometime in the next couple of weeks – busy season at work and this is still a hobby.

“A Real ____ Would Be___”

Since starting, a few members on forums would always say ” a real maker would be making furniture ” or what furniture or how. Knots was full of Taig Frid acolytes, but I doubt any of them were legitimate fine makers of anything. They’re acolytes – at least self-appointed – of the people who were writing articles in magazines when they started out. Knots was pretty toxic, but it was closer to the average adult just getting on the internet and feeling like they could say or do whatever they wanted, failing to admit to other people that they were…..well, a failure.

One with a numeric name would tie you up in anything. I don’t know what his point was, but I think it was the careful craft of implying that he knew something and just enjoying the endless text referring all of the things he knew about against the things you were doing. I ran into him after making an infill plane. He instantly showed up and told me no real woodworker he knew would use an infill plane. Well, I don’t really use one much either – I made the plane. that was the point. I’m grouchier and older now – I’d instantly ask him for a portfolio of his work, the name of his woodworking business and thoughts on how much of the household share it takes on.

One of the other animals there turns out to be a tax preparer, I could never find a portfolio, and business attempts by court documents end in bankruptcy. I guess the bankruptcy filings are their portfolio. That’s what they make other than a hassle for you on the forums. Why would you look for a portfolio? Well, first, if someone loves Danish modern or CNC use, finding their portfolio would kind of tell me at least that I’m not looking to do things the way they do. You may be.

What you’ll usually find, though, is no portfolio at all and digging deeper just finds things that will make you wonder why you’d take any advice at all. Especially about what you should do with your time when you really are interested in something other than going bankrupt. Or making furniture, or whatever else.

You can probably get pretty good at deciding exactly what you want to do if you’ll allow yourself the freedom. Even if that’s doing something that involves impressing others (more power to you) by doing just what everyone else is doing. I’m not a real anything in my leisure – it’s really enjoyable.

.

.