This may sound like an odd title, but you already know of a baked varnish. Ashphaltum japanning. Coincidentally, the older texts refer to something like a gilsonite asphaltum japanning as a cheap finish. Japanning was used on a lot of metallic items in layers, with the higher quality work being a base and then clear varnish on top. Things like sewing machines, and so on, and decorative items for high class, probably up from there.

But experimenting while tempering some knives last week, I put the long oil tung/linseed varnish on a knife blade that I had sitting around – one that I made early on and will probably never turn into a knife because it will rust faster than rust. The hardness of the baked long oil japanning was shocking. That on the wood can still be dented by a fingernail and it’s a couple of weeks old and may always have this level of pliability. But the baked varnish was stuck to a knife blade that was just bare metal and not that easy to get off. it didn’t shatter off like paint – you could scrape it off but you had to scrape to the metal. No prime, no cleaning the metal, and so on. the color of the varnish in what was probably a 400F cook, though, was a dark straw. I was tempering knives at 340F, but the test blade was exposed to the radiating heat from the elements while the knives were safely tucked in between two really big thick plates of aluminum to block that.

Black Japanning and What?

Asphaltum is actually a dark brown, but you get enough of it with metal behind it and it looks black. it becomes the resin in a varnish and it crosslinks to the oil. You can do that cold and cook hot enough for it to become a varnish after it’s applied, or you can do like I did and just cook it together and keep it like that so that there’s no stirring in the future and no settled anything. I prefer that.

But it triggers any reasonable or unreasonable person to say “what else melts around 350F and crosslinks with oil. As in, is there a whole palette of colors that might be available by simply finding natural resins. I think the answer is no. I’m sure there are others, but it’s too complicated.

So it may seem like there is something about asphaltum, and there could be in terms of how it chemically bonds with metal. But the long oil varnish is worlds better than any spray paint no matter how good the spray paint says it is, and it will cost little.

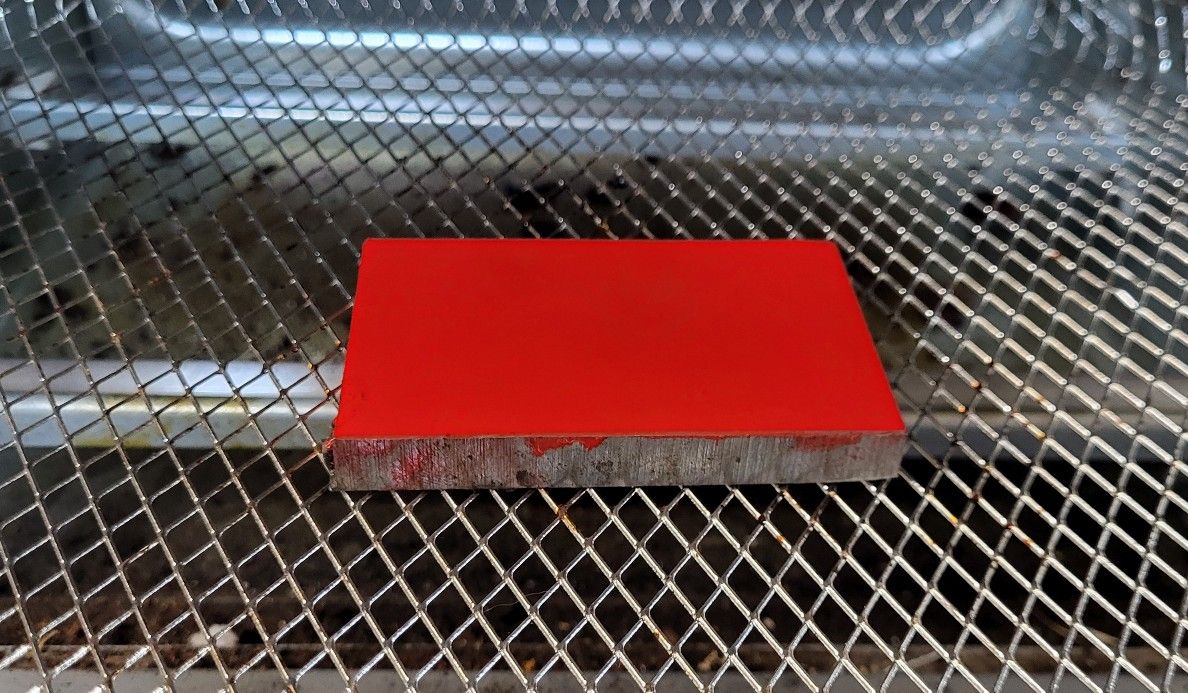

Knowing that it went to dark straw, then the question is – what will look good? I think a mid red and a mid dark, but bold and deep blue would potentially be nice on tools, and comparing a lamp black base long oil varnish to the asphaltum japanning would be interesting. I shot very bright on red pigment to try the red, and here’s what it looks like:

Cadmium red. Not exactly maroon. The long oil varnish is in the bag and you can grind or mull pigment into oils and finishes, but I’m not doing that. We have some freedom here, though – adding oil to this mix with mulled pigment in it would be no big deal due to the reality that in a cook, it would just crosslink with the varnish and still end up with varnish.

This idea of how good the varnish is baked isn’t something unsubstantiated – the old texts talk about the varnish being superior when it’s baked instead of drying by other means. You just can’t bake everything at 400F, though, even though there are some references in terms of how to prep wood to try, anyway.

Laying this 80s-reminding color on a chunk of steel gives this:

Pretty bold. One coat left marker on the steel “80CrV2” still telegraphing through, and a second problem. The picture above is after slathering another coat on if I recall.

That problem is crows footing or whatever you’d like to call it. Which I believe is always or maybe almost always the result of the finish skinning and pulling on itself before the layer below has given up all of its solvent.

The result is this, though:

The color isn’t darkened much, either, but I cooked this at 350 and shielded it some. it needs more heat to become a bit more subtle in terms of what I was expecting.

Less heat to start, or really low heat for a while is an option, but the other that may be more intelligent is just to let the varnish gas off and cure for a day on the piece and then bake it. I’ll see how that goes.

At this point, the second prong of this – cooking at a higher temperature to darken the varnish to a less bold color is in the works.

it’s the durability of the varnish that’s desired here. It would be lovely if the top layer was glossy, but we can actually do what they did for higher quality work, which is to set the color based on the finish applied as the base, and then bake another clear varnish application on top.

Cleanliness when applying the varnish is key – any little piece of dust or anything, even metal sanding dust from cleaning off the steel results in piles of little dots. One of the things that varnish really loves to do is take a tiny fleck of dust and stick to itself (the varnish) above that dust and make it look 100 times as big. it could be that the solution to that is still adding un-cooked oil in with the varnish so that the finish lays out more like a lacquer, but we’ll cross that bridge only if we need to. if you look at the japanning on any older plane you have, it’s good, but it doesn’t look like an automotive finish with no imperfections in it.

I don’t have a real need at this point, but I’m curious. I wouldn’t mind ruining a few older planes with surprise colors, but done so well that it raises the question “why would someone who can do something that nice do something that wrong?”.