Some years ago, I heard about Garrett Hack charging oilstones with fine diamonds. But, I didn’t hear it from Garrett. I heard it from someone who disapproved of it and was sure that it would result in less fine edges.

When doing the “sharpening omnibus” the first time, I found that lightly abrading a broken in translucent arkansas stone didn’t result in the decline in edge quality that I expected. As in “making a slurry”. So, I’d forgotten about diamonds in fine natural stones (not friable ones, but hard ones -why bother putting diamonds on a stone that self slurries – they’ll be gone quickly) until then. Previous tests (for me) of diamond grit found that there’s no real benefit to using diamonds to finish something unless they’re really fine. As in, I tried 5 micron and 3 micron diamonds to see if there would be a fast but fine medium where someone (including me) could grind and use one honing grit and that’s it. It didn’t work out well – a 3 or 5 micron diamond edge is coarse unless the diamond is on a soft substrate. I never tried it on pine, but maybe it would work. The reason that I didn’t try it is simple – 1 micron diamond doesn’t cost any more and it works finely on anything.

How finely? it outlasts any natural stone that I have (and I’ve had hundreds) in planing edge life. Not enormous amounts, but measurable, and the initial sharpness is greater. You can be as good as you want to be with natural stones, but you cannot practically make them match smaller oxides and diamonds if you’re just chasing the limit.

After doing the slurry test mentioned above, I lost my vial of 1 micron diamonds and until this week, never got another one.

Now that I have 1 micron loose diamond (which costs all of $8 shipped on ebay), I figured I’d give them a whirl on arkansas stones – knowing that I have zero interest in using coarser diamonds.

The test subject in this case is a Buck Brothers socket chisel – but an old one and one that’s harder than Buck Bros Cast steel tools typically were. Subjectively, it’s about like better old English tools, and comparable to the best O1 tools you’ll find (like iles bench chisels).

First picture – Dan’s Black and 20 seconds of work and then hone the bevel. No stropping is done in this case, and no buffing (the buffer would run enough off of the edge of this that the disturbance at the edge would disappear in favor of a perfect line – it’s good for that, but it makes comparing the stones themselves a little harder). No diamonds are used for this edge.

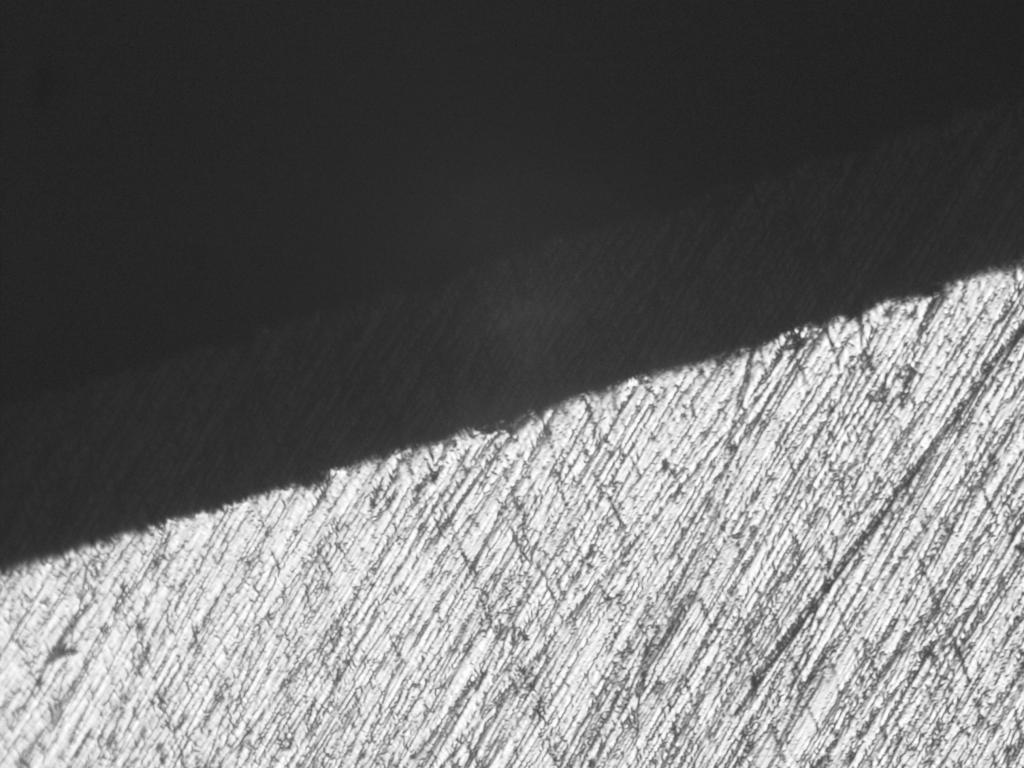

Dan black Only – 150X – nice uniform bevel

It’s possible to use an oilstone and finish an edge better than this, but the reality is it will take successive sharpening and a lot of care. Since this is a hard chisel, the stria are close together and small, and despite not stropping, there’s little disturbance at the edge. When this is done in the next blog post, I’ll work back around to refinishing this edge with the black stone again just in case the little spots are minor pits (very minor). A black arkansas is a slow stone, so the practical part is you can use a lighter and lighter touch quickly, but to use it to get a much brighter polish would take minutes just on the back of a tool at each sharpening session. Practical is to apply directed pressure and then lighten that pressure.

Second picture – same stone, same edge, but after sprinkling 1 micron diamonds on the stone and adding a drop of WD40. This created a slurry, but the more dry stone (less oil and not a puddle is nice with fine arkansas stones) acted as a brake with the diamonds and literally kept from being able to move it.

I noticed two things after 20 seconds of work – there was no grip on the stone with WD40, so something between nothing and what I had may be nicer. But second to that, no wire edge formed when honing the bevel on the opposite side. A black arkansas stone will form the finest of burrs, but you can still feel it if you don’t work it off of the tool or strop it off. It’s not there with the diamonds.

Same as picture 1, but 20 seconds of work on the back of the tool with 1 micron diamonds on the oilstone. A small improvement

How much of a difference does this make? Visually not enough to conclude anything. Less lubricant would’ve made it a little easier to get the diamonds to bite.

Third picture : so, I went back for another 20 seconds hoping to see if I could hone off any disturbance at the edge.

20 more seconds of back work and more refresh of the bevel – 40 seconds total of polishing on a fine black stone with 1 micron diamonds loose on the surface.

Some actual testing of the edge in something comparable is probably needed to really be able to tell if it’s an improvement beyond just different visually.

Again, no wire edge.

My head is full of thoughts or questions about what’s happening with 3 micron natural particles fixed in place and 1 micron sharp particles moving around. I can’t see any evidence that edges are degraded (no surprise). But before using no diamonds: Fourth Picture – one more shot with the slurry dried off a bit so that it’s stronger cutting.

This suggests that the tip of the tool above just wasn’t yet honed off (either from the back, or more realistically, by shortening of the chisel with successive honing).

The lack of any real burr is kind of a treat. That suggests that if you’re using a two stone regimen, you can eliminate teasing the edge off or stropping. Will that last forever without a fresh slurry of diamonds? I don’t know. That’s maybe beyond my scope here. Next item for me is to see if the diamonds that come from china in 100 carat lots for the same price as 25 from the US ($8 or so) are equal in quality.

While these pictures all look different, I can’t say definitively any of the above differ much – none looks like a laser cut edge, but all are very good quality edges suitable for anything, and super uniformity can be had with very light buffing if needed, or removing any remaining burr with autosol on wood. I will make a note for myself to do this same treatment to a plane iron – ark only, ark and diamond and then ark and autosol – and see if anything creates a drastically finer smoother shaving.

It’s worth going back now and honing this chisel on the arkansas stone only now that any initial anomalies should be honed out (be they lagging minor corrosion or whatever else, so here’s Picture 5 – honing again on a section of the stone that has no diamond (luckily, this is a 3×10 stone so there’s fresh space remaining).

…….

later add: I was interrupted just as I was about to post this blog entry, and the interruption made me think. Maybe I should compare diamonds as I do have a high quality cast plate (recall prior posts that if you just try to turn a plane bottom over and use it, especially if you have to abrade it, you’re not going to get ideal results).

So, Picture 6 – diamonds on cast. In this case, there’s a load of diamonds on the surface and if allowed to embed in the cast, the cutting speed would slow some over time before refreshing is needed, but this cut will also get finer (as in, this should get closer and closer to uniform polish). This plate has been sitting for over two years, so there could be all kinds of things on it that I don’t know about that are leaving deeper scratches (Dirt, little rust particles, etc) – who knows.

I’m not sure we learned anything I hoped we would, but the pictures do make it clear that if you’re sharpening to this level of fineness, you can’t damage edges and expected the fine abrasives to recover them.

Hi David, as always, interesting stuff you are covering. I had to think twice about the larger surface equating to less overall pressure (per square inch or mm) but it makes sense in the end.

Can you comment on the use of 1 micron diamonds on a Washita stone vs a Black (or white for that matter) Hard Arkansas stone? I’ve used the former often with diamonds but never the latter.

LikeLike

Hi, John – I don’t know that the 1 micron diamonds cut fast enough to do anything on a washita unless there’s a big enough slurry of them to prevent a wire edge formation.

Do you know what folks were using when diamonds first became available? I recall maybe 15 years ago, a small syringe of norton paste was more than 100 carats if diamonds are now and probably had about 5 in the syringe. I’m sure there was lapdiary supply back then but the market from china organizing directly to the US probably has something to do with there being $8 vials of very fine diamonds, and then four times as much in a baggie for the same price from china.

Long story – what I’m leading toward, is I wonder if folks were looking for finer or faster? The finer idea here is interesting, but it sidesteps that the diamonds are a little more crisp working on surfaces other than an oilstone (reminds me that an agate test is in order as the agate is really not worth much on its own). If looking for faster, 2 or 5 microns on a mid stone would be interesting as long as the stone has the gumption to stay in place under the tool. I have #2.5 micron and will give them a whirl on a washita. I’ve got a lot of thoughts (one of my favorite things to do with a washita is temper a tool to be an even battle and then the washita can hone as finely or very close to it on a flat edge as can a black stone with pressure. Diamonds would lose that, but also make the stones capable of finishing things the stones themselves can’t finish.).

2.5 and 5 microns on cast were no go. The brash edge left behind was harder through wood than anyone would expect leaving a dull surface despite confirmation of the edge under a scope and enough stropping to get rid of the burr and remnants.

At any point, any information on what folks were doing? Were they looking to speed up natural stones instead of supplement them to a finer result?

LikeLike