Well, to start out with, I ended up getting banned from a knifemaking forum because I wanted to talk about heat treating in a forge. But I really went there in the first place to try to find 1095 with upper end of the spec chromium and a little bit of added vanadium. That would make forge heat treatment really easy. It turns out, you can solve (if you’re me) the issues with 1084 and 1095 pretty easily just by manipulating temperatures by eye with some samples, snap them, and then make actual tools with them and confirm they’re better. But I didn’t bother to do that until I got berated about “poor results” from one of the most undesirable individuals I’ve ever met on a forum – Devin Thomas – the father of the metallurgist who did my test results for 26c3 and O1. I later sent more samples, as I’ve mentioned on here, with 1095 and 1084 without looking much at them just to see how they’d turn out.

The 1095 was mediocre and the 1084 was undertough by a lot. What resulted was finding out that though I’ve never talked to Devin, he was pretty pleased to see the second set of results from steels I don’t generally work with and pretty excited to ignore the fact that my other samples were as good (O-1) as book results and never-to-be-mentioned, I guess, far better than furnace schedule results for 26c3. Those weren’t by chance.

What is the problem? Apparently, Devin, who is by others accounts an accomplished maker and provider of some materials to other knife makers, doesn’t like anyone to talk about heat treating in a forge. I don’t really care what he likes, but he doesn’t know much of anything about woodworking tools and I couldn’t get discussion out of anyone else about questions that had nothing to do with it. He gets my award for the least desirable person I’ve come across on any forum for inability to discuss something unrelated to what he wants to drone on about. So, eventually I got banned for talking about heat treating in a propane forge and posting the results because I refused to stop talking about it. The official reason “poor behavior and being suspected as a returning troll”.

This is BS, of course – I don’t have more than one ID on any forum and have a distaste for people who maintain multiple logins. I can’t think of a single person who does that and adds anything positive to any forum.

I may also be underestimating the whims of advertisers on the forum or other paying service providers. In short, talking objectively about what you’re doing and after much goading, showing factual results that aren’t in line with assertions you weren’t asking about in the first place? It must be some kind of threat.

The very simple fact is that by not following published schedules, I got better results than anyone has ever published with 26c3, and it breaks the rules of not normalizing steel and then giving it an austenitizing soak before quenching. I had no idea those things were supposedly rules in the first place. they can be needed for some steels that do need them – 26c3 doesn’t. If far better results than steel done with those steps isn’t proof, I have no clue what is.

What resulted when I was found out to be a forge heat treater and then my comment that I wasn’t getting a furnace in the near future, from Devin, is something I wouldn’t have expected to see from a grown man, but life is full of surprises. I did later scroll back and find out that i’m not the only person who has been subjected to it, and there’s a whole group of (maybe well meaning?) sycophants who will request the moderators ban anyone who posts methods they don’t like. I suspect posting results that support them is even less well liked.

Where does 52100 come into this? I got the same thing I always get from people who have made knives when I don’t mention 52100 as a preferred steel.

What’s the problem?

52100 is very different than other relatively plain steels. It has an amount of chromium in it that gobbles (binds) a lot of carbon so that the carbon doesn’t remain in the lattice/grain framework. It’s also offered in a lot of inexpensive bar stock in very different starting structures. Some of those structures won’t achieve good hardness, especially if you just heat it to nonmagnetic and then quench it.

I have worked enough with it to know that I can get it reasonably hard in the quench – to the point that it’s difficult to deal with sharpening comparatively – in woodworking tools.

The lack of carbon in solution appears to make it too tough. This is a foreign concept for knifemakers – “too tough”. Tough keeps people from breaking knives – they bend instead. I don’t think people have the cajones to return a knife they bent but that didn’t break and then claim they weren’t abusing it. That’s great for a maker. Let’s be honest, too, few people are doing much with custom knives they buy outside of some really strange competitions that look just ourtright weird to anyone who is a woodworker. The average person is pushing a knife through things or slicing with said knife.

When I first started playing with it, I expected to find low hanging fruit, that 52100 hadn’t been used, and maybe it was a mistake not to use it. Maybe the reason was that it was harder to heat treat, or who knows what. I suspect that the early 1900s tools from the carbide patterns that I see are lightly alloyed water hardening steels with some addition of tungsten, and some may be oil hardening steels when they’re solid. but I don’t think I’ve ever used a tool that behaves like 52100.

Everything used in woodworking has enough toughness, but not an excessive amount. You wouldn’t expect to take a chisel, bend it over in a vise into an L and bend it back and not have it break, but 52100 can do things like that without breaking outright.

First Experiements

I made a couple of blades of all kinds. 52100 was one of them. Disregarding effort made, it planes about as long as O1. I didn’t test it directly against O1 right away and figured it should be good. it also has a persistent wire edge at “normal” plane iron hardnesses. In chisels, I found the toughness intolerable – when an edge would deflect it would just stay there increasing the cross section of the edge and making the chisel harder to get through wood. An unexpected problem.

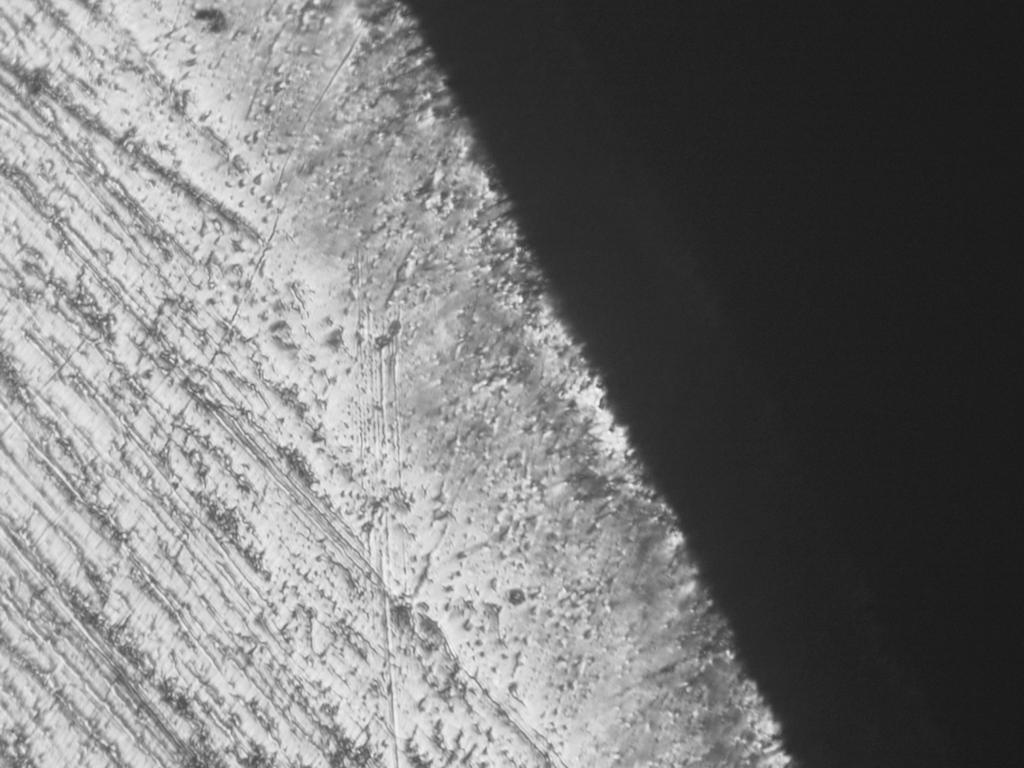

I later compared a couple of the irons that planed about as long as O1 and noticed that as the two steels wear, 52100 takes more effort to keep in the cut and on woods that a plane likes to come in and out of the cut on (figured or runout), the cut was more rough at the same interval. that creates a big difference in physical effort even if both irons plane the same distance, and planes not staying in the cut is part of the reason the average person fails to get a finish ready surface off of a plane. This is what the carbides looked like – they were a little larger than I would’ve expected, but evenly distributed and all in all, not bad.

Compare the edge of that picture to O1

I think there is a fundamental difference in how the edge wears – how round or blunt does it get, and how does that effect planing.

O1 does not keep carbon out of solution the same way 52100 does and the alloy is different, but it’s easier for a fast heat treatment process to get a lot of uniformity. I think moving the cap iron around would show a few more carbides, but it’s not a surprise that they aren’t as vivid. the “stuff” remains in solution and creates a problem that metallurgists call plate martensite. This problem reduces toughness…..except for woodworking, I’m not convinced that it’s a problem.

Knife folks are still fixated on the fact that you can break O1 – what are they cutting? I don’t know. I think they cut the cheese more than they cut things with their knives. We don’t have that luxury in woodworking.

I keep coming back to O1 being a really pleasant steel for woodworking, but I’m not trying to create an argument for it – I’m working from outcomes first, which can be unexpected – it shouldn’t be better according to anyone, but if it shows better in outcomes every time, and it’s also easier to heat treat, and the issue of toughness doesn’t apply to us, maybe it would be smart not to deny the outcome. Even if you never figure out the cause, the better performance is right in front of your face. And if you hand plane 15 or 20 board feet from rough in a day, that difference will be drastic. It can work longer into the dulling cycle without you as the “planer” having to sharpen as often or you as the planer leaning on the plane and really creating a lot of problems that are both unpleasant and unproductive.

I also noticed while looking at grain size that these 52100 samples were outright abusive to my vise. I break samples by hitting them with a hammer. I want to see the grain size under a microscope – but you can also feel a difference in how hard you have to hit the steel to break it. A tempered factory file will break easily. A 3/16″ thick sample of 52100 that’s even moderately tempered may actually be a threat to break a vise.

what does that clue us into? the next reasonable thing is to leave it hardly tempered or untempered and see if the edge holds together. it’s really unpleasant to sharpen when it’s left really hard, but it’s not that slow to grind. the washita won’t touch it. Why is this reasonable. It’ll be much less tough at really high hardnesses, but it may still be tough enough almost untempered to plane wood without chipping.

Figuring it would chip and then I would walk back the temper until it didn’t, I was wrong. it didn’t chip untempered. It was, however, a right bitch to sharpen when compared to tempered irons. Slower even on diamond hones. there’s nothing in it diamonds won’t cut easily, but at some point, harness can be so high that the diamonds don’t penetrate as much.

But…compare the edge to O1. I don’t know if the picture is meaningful, but the edge rounded look is still there………and the result of planing is that it again felt really keen initially and then continued to plane, but it doesn’t have the sweetness of O-1. the combination of attributes doesn’t offer anything. Again, a surprise.

I Put it Aside and Got it Out Later

After being goaded on the blade forums (and then banned for talking about forge heat treatment, or because of the outrage that the topic causes), I decided I’d see if I could get some of the carbides in solution without a furance. I don’t think this would be that hard. Here’s the thought process:

Larrin posted an excellent article about how much differently 52100 turns out in a furance depending on the initial microstructure. Some of this is canceled out by the fact that I use a temperature overshot when heating and no real duration, but probably not all of it.

When I first used 52100, i heated it a couple of times and quenched it, and tried a few things. Since then, I’ve learned to shrink grain with extreme reliability. I also think I can manipulate carbides a little bit without having too much carbon escape the steel. Again, a very high heat overshot, and then something I haven’t done before much – heat to critical with another iron (for mass) and stuff it in vermiculite. the hope is that I will get carbon back into solution (less toughness, higher hardness yet), and the thermal cycles will shrink grain without moving much of the excess carbon in the lattice back into carbides.

I would then follow this up with a temperature overshot quench (heat to a brighter orange as fast as possible then quench as fast as possible back to the lowest temperature possible). I have all of these mule irons on hand already, they’re just waiting to be turned into knives or something instead, but if I can actually change how they look under the scope, I will know I’ve changed the outcome without any question as to the difference in the bar stock used.

So, I did this – I know conceptually this is difficult to follow. But here are the same irons with microscope at same magnification. Apologies if the light reflection is slightly different.

First iron, 350 F temper, which would be untertempered for O1:

I would estimate this first iron’s hardness at 62 based on the stones. the washita doesn’t do much with it, but it’s not intolerable. it cuts OK on an india stone. As with prior versions, the burr is persistent, but I’ll let the buffer deal with it.

This is after planing. Look at the edge again – it still looks like it doesn’t have the uniform sweetness.. And it doesn’t. It just doesn’t perform as well with thin shavings.

The hardness is a little better that before. Did I do what I think I’m doing? I have no idea.

so I did one more iron with the same thing, one of the ones previously made, and tempered it at 300F instead. It should be around 64 hardness. It feels like i is. the washita has no interest in it. For reference, the abrasive particles in washita are about the same hardness as rockwell C64. If you slurry an oilstone, it can abrade steels harder than the particles, but the mechanism isn’t by rasping grooves in the steel.

this harder iron is unpleasant to sharpen if you’re used to something like 62 hardness O1. It’s not more abrasion resistant, it’s just harder.

The edge is maybe slightly finer and if I didn’t take too thin of a shaving, the plane wasn’t unpleasant to use. However, it wasn’t better to use than 62 hardness O1. it still exhibits more of a decline in ease of use through the dulling cycle.

I’m not sure exactly what I’m seeing, but I think for this steel and for 1084 at higher hardness, the edge wearing actually forms a bit of a burr, too, or something that reflects light in an unexpected way.

Whatever it is, the outcome remains the same. It’s just not as nice to use on wood.

And, I think that fact – that you can feel the difference and anyone actually making tools when people were acutally using them could feel the same has a lot to do with why we don’t see ultra high toughness steels in woodworking. No matter how much some knifemaker tells you “it doesn’t make any sense”.

The sharpenability of lower alloy steels like this at really high hardness is there, too. It doesn’t make sense to someone not sharpening in volume why it would be an issue, but you don’t get double the edge life for double the sharpening effort, and that’s ultimately going to be annoying to experienced woodworkers.

Hi David,

Thank your for busting the myth about 52100 steel as a better steel for ww tools.

I remember about 4 or 5 years ago, in a Chinese woodworking forum(the biggest Chinese woodworking community), one guy posts that plain high carbon steel is plenty good enough, maybe even better, for chisels and plane irons, the post grew over 80 pages, It’s like this guy is fighting a war against the whole world. I guess that is just internet being the internet, anyone can post anything without knowing anything or with any proof. A lot of ppl consider that GcR15, the Chinese equivalent of 52100, is a far better steel. Of course, the “high end” steels are being mentioned in every other reply to the post too.

Since then, I have developed an interest in this steel, but was unable to find any that is readily available. Now I can put the idea to a rest, thanks!

LikeLiked by 1 person