After the debacle in the first three posts about Magnacut where it looks like my sample benefitted from having the initial bevel ground off to get to harder steel, I figured it would be interesting to pattern carbides. I’ve only had one steel that wants to defy this – AEB-L. AEB-L wears in a kind of weird shape, and very smoothly and it just looks like grease or clay on the worn surface. This would seem to be a good quality as it suggests “ultra fine” visually, but AEB-L wears longer than 80CrV2 and O-1 – without cutting as keenly as it dulls. It’s noticeable, especially if you use both in the same board and there is figuring or anything other than easy planing.

My typical trick to expose carbides is to set the cap close so the chip rubs against the back of the iron and then plane cherry, which has a “dry” feeling when planing. I have the same maple from the third test in the vise, though, so I’m using that. I noticed three years ago that the wear on irons looks different from maple than it does from cherry or beech. I don’t know why this is, but it leaves a smoother looking surface. Maple is less nice to plane than beech because it doesn’t accept an edge into the wood as easily, but it doesn’t seem to plane much less in footage before dullness.

Anyway, I expected to see a dense matrix of small carbides in both of these samples based on what I saw from cherry, but the pictures show a little more subtlety.

What to look for

I’m generally comparing what the edges look like, the carbide size, uniformity and prominence, and then feel as the edge dulls. You can’t get the last from reading this. Feel importance to me is how easily an edge planes and how cleanly it planes features. For example, 52100, for some reason, is never as sweet as O-1. If you plane a figured surface with it once it’s even been in the wood 100 feet, it will require more effort to stay in the cut and the actual surface will be more scuffed and scratchy feeling.

Surprisingly, AEB-L with its ultra-fine look also does this. O1 is reasonably “sweet”, 26c3 is very sweet (but less long lasting than O1) and 80Crv2 is very sweet, meaning that even as it dulls, it seems to enter the cut and stay in it better. Simply put, I’ve tested AEB-L in the past and found that it would last a lot longer than O-1, but I would use O-1 because it’s less work to use, anyway. Neither is hard to sharpen, but O-1 does sharpen and grind a little faster, which you’d expect.

You may not feel how drastic this difference is between various steels without sharpening them similarly and then planing alternating in the same piece of wood.

You’ll have to take my word on sweetness because I haven’t found a visual characteristic that’s 100% reliable aside from a ragged edge will not be that sweet, but not every uniform looking edge is that sweet. V11 looks like 52100 on steroids (same type of carbide), but V11 has pretty good sweetness if you can avoid chipping, and 52100 doesn’t. Seems backwards since V11 looks more toothy.

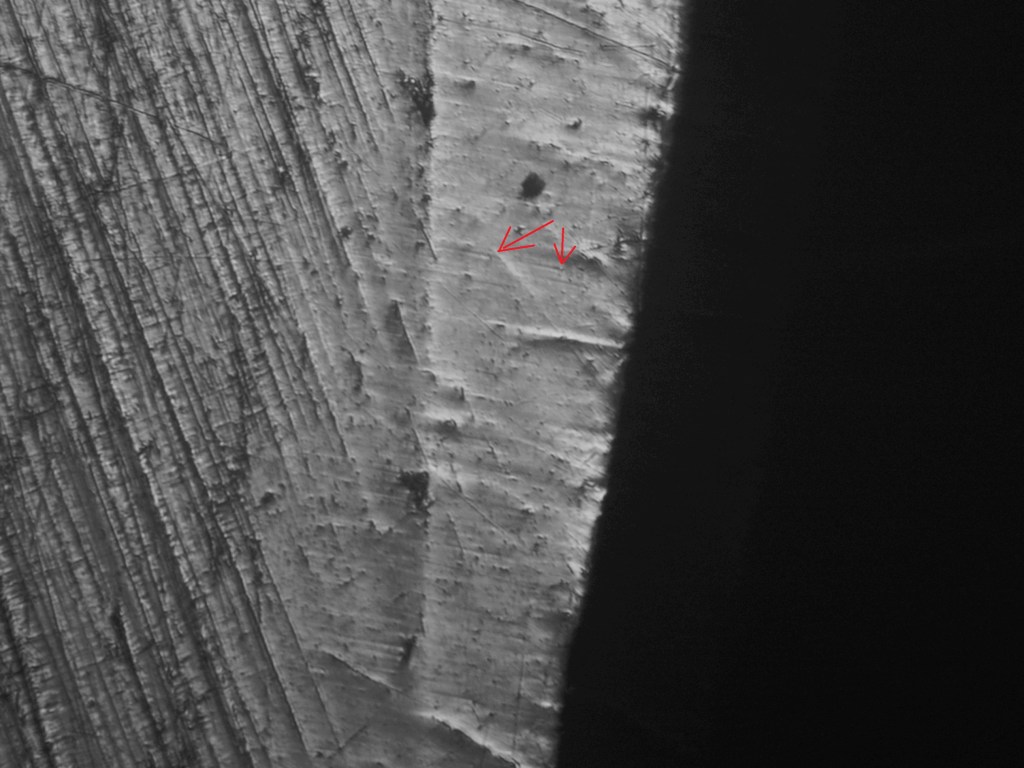

Magnacut Smoother Wear

Magnacut 300x magnification – smooth look, decent edge, but strangely wavy with wear. Reminds a lot of AEB-L even though the composition is much different.

Notice the red arrows. it’s no easy to see the carbides, and it appears the final sample as mentioned before shows the advertised fineness.

Carbides and steel grains aren’t the same thing. The actual steel matrix grains are bigger, but I can’t show them without nitric acid, which I’m not looking to deal with as it would necessitate storage in an external shed based on my physical carelessness with things. So, the grains are an unknown, but the carbides are definitely small and no big odd ones appear.

At the edge of the arrow, you can see a carbide with its “comet tail” where steel was protected behind it. The rest of the smooth structure reminds of AEB-L. which is better would be up to you – AEB-L irons could be made available pretty easily, but I’m not sure there’s a market for them and personally, the sweetness of 80Crv2 is worth a lot more to me than the extra edge life of AEB-L. The comparison of the two steels here finds the same with Magnacut. It’s an interesting steel, but I wouldn’t swap it out vs. 80CrV2 or O-1 at an appropriate hardness level (as in, not soft, and not pushing the upper limits of the tempering range).

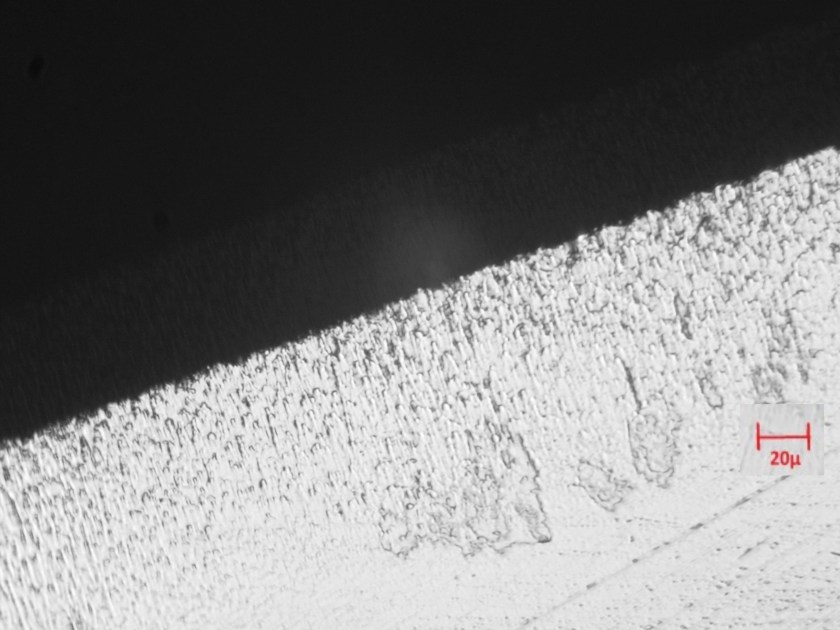

To get an idea of how small these carbides really are and how fine for both of these vs. a steel with larger plentiful carbides, I’ll toss a picture of XHP’s (PM-V11) carbides at the end.

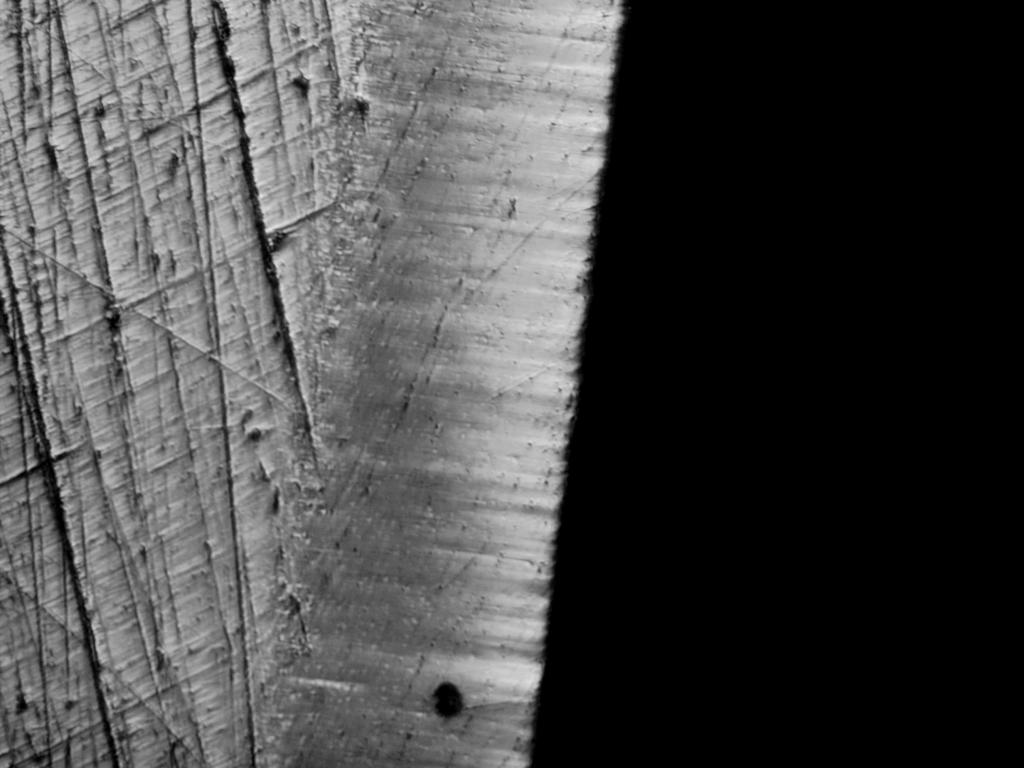

80CrV2 Smoother Wear

I put a picture of 80CrV2 wear in another post already, but this is different wood, so it’s appropriate to take another picture. I got lost a little bit in planing with this so it may have planed a few more feet than the Magnacut iron. Regardless, it’s clear that it wears faster when planing, but it has excellent sweetness remaining keen as it dulls. As good as anything.

80CrV2 at 300x – notice the smooth but considerable wear, and the smoothness of the edge. The tiny dots of carbides are easy to see. The faint diagonal lines across the wear bevel are oil even after wiping off the bevel four or five times. This is an illustration of why even when you think you don’t have oil on your tools, they will benefit greatly from using oilstones to sharpen instead of waterstones.

Visually, 80CrV2 at this very high magnification looks more uniform at the edge. It feels like it as it just cuts more smoothly in wood. Edge life is similar to higher hardness O-1 based on my testing and may be even a bit less. Not much, but a little.

Day to day cost neutral, I’d pick this over Magnacut. There’s not much technically interesting about it compared to newness of Magnacut, but it’s just a little nicer to use. It’s also nice that it’s dirt cheap but for that barrier that you need to make your own irons if you use it. It’s also not stainless, but stainlessness of irons only became a “thing” when the folks imagining woodwork became the majority over those who are actually doing it, and the whole tool care hocum is a product of selling nonsense to beginners who think there’s magic in little 1 ounce bottles of “nano-quark” rust preventive pushed by their favorite ethically-deficient influencer. My suggestion? Use oilstones. If that doesn’t stop rust, then cut back the number of tools you have and use until they’re not rusting.

My eyes are still open for the next steel that’s going to be better, functionally, without making conditions. Like something that wears twice as long as 80crv2, but has the same sweetness and actually makes for less work. I don’t know if that’s practical. Magnacut is a good attempt, but all things considered, it doesn’t get there cost neutral, but it would make a dandy kitchen knife at this same hardness.

Dandy enough that I think Lake Erie Toolworks should think about finding someone who would grind chef and paring knife kits out of Magnacut leaving just a bit of finish sharpening and handle fitting for folks. It’s again something I wouldn’t be interested in, but there’s the inclination in my mind for someone to “adopt a steel” and be willing to buy more than just irons. Especially if they can get them at the same place. They would have to be expensive given the cost of the steel, but none of this is aimed at the teenager who is choosing between their next plane and duct taping shoes for a couple of months.

And, finally….the picture of XHP that I mentioned I’d link here again for comparison – this really puts into perspective how small the carbides are in the two steels above.

CTS-XHP wear after planing – 300x magnification. Notice the density and size of the carbides. This is likely the same steel as PM-V11, and if not, it’s insubstantially different. The large carbides do not, though, correlate with poor keenness while dulling. V11/XHP have nice sweetness while wearing, with some tendency to nick and a long potential edge life that increases the chance you’ll gather nicking.

Slightly off the main topic: I’ve often wondered why I’ve never had the problems with rust that seem to plague others. And I guess the answer is that I’ve always used oil stones.

Also: “ethically deficient influencers.” 😂

LikeLike

Yeah, that last line is a bit redundant.

If an “influencer” could peddle an aliexpress version of this iron and get a big commission, we’d hear all about them, but the quality is too high for those guys. They’d smile as they make the same workbench and jig they made 4 years ago in a new video and pretend they’re progressing, and refer to Paul Sellers as if he’s a “colleague” or as if he was a meaningful fine maker of some sort. Weird alternate universe.

Oil though….highly underrated. Oil combined with actual use and touching tools. Who’d have thought. Occasionally, I’ll have a new iron that doesn’t get much contact rust a little, but my well used tools don’t rust in a shop that sees 30F to 85F and humidity well above 65%.

This iron is an interesting honest effort – but like everything else subject to experienced users, the novelty may wear off. I would love to see something like 80crv2, but wearing twice as long, twice as hard to nick and just as sweet when it dulls. I’m not sure if that’s actually possible.

LikeLike