I can show you tools that I’ve made. I’ll show you the second saw handle that I ever made (I’d made a few plane handles before this, so there’s some cross over).

This saw handle isn’t the inspiration. This is the second saw handle that I made, as mentioned, but why it’s important is because the first one that I made was “good” by first standards, but it was not similar to this. I can see now why that was the case. The horns are better on this saw, curves are natural, the transition lines are stark, the pip is sharp, and I managed to find buttery quartersawn apple (never have been able to since) to make the handle. Notice the curves on the inside of the handle at the front, how the handle isn’t just flat, and the dynamics of the curves aren’t just a round over or routered look.

I learned about this stuff right away when I made this handle. This is the first anything I made after George Wilson saw my first handle online and said “give me your phone number”. I really didn’t want the obligation, but have to admit running around in a jelly diaper (figuratively, as a woodworker) seemed lacking and I knew the first handle would be fine for sawing, but direction after that wasn’t clear. “I’ll get better a little at a time” was comforting, but I didn’t know what combination of execution vs. just not knowing what it should look like existed. it turns out that even though I’m by no means great at anything, it was 10% execution and 90% just not knowing what the outcome should look like and why.

George laid that all on me at once. I feared failure. the handle isn’t perfect – the lamb’s tongue is miles better than the first (which was the same thickness for its entire length – no animal that looks like a lamb has a milled steel parallel thickness tongue from end to end). George also didn’t give me quite the step by step that I mentioned above, but he talked about aspects and what would look better, and I took a risk and did it. The risk was posting saw number two and not knowing george well, having him tell me that it wasn’t very good. I was already 10 years into a white collar career and to find out you’re “not worth a shit” at something else is a big threat.

Except it seemed almost like magic at the time when I was done. Looks like the wood has shrunk a little since then and the screws are proud. Oh well. I needed the saw at the time and it performs that function well.

But this isn’t furniture and only furniture counts

That’s often said. I think it’s limiting, as mentioned, if you want to find something where you’ll go broke – try making a business making fine high skill solid wood furniture.

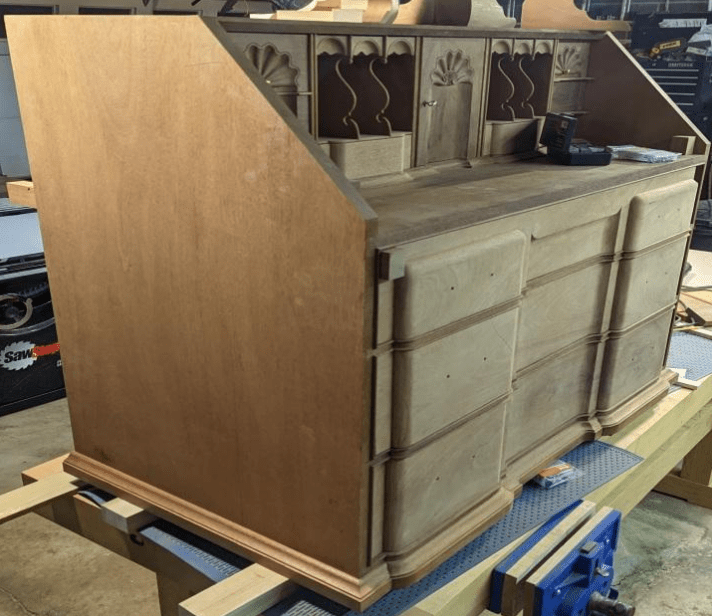

Someone sent me this picture yesterday – this isn’t my work.

I don’t even know the person who did this work, I just know who sent it to me because they were inspired by it. Look at the fronts, look at the base moulding and the beads and the carving. The carving is crisp and clean and has excellent symmetry and depth.

And though it’s a different skill…look at the side. that looks to me like it’s one board. i asked if it is, and it is indeed a single board of mahogany (!!!).

the drawer fronts will be carved and the piece will get hardware and finish and who knows what else.

I requested a grapevine message be sent to be returned about whether or not I could post this here. Why?

The sender told me that the maker of this desk has only been woodworking for several years.

Think about that.

It reminded me of Wyatt McQueen, who came out of Thaddeus Stevens college east of me able to make furniture like this probably at age 20, and maybe since Wyatt was and is a pro, it’s even beyond this.

I saw Wyatt’s furniture on display with Wyatt presenting them, much younger than me at the time, and it was a real lesson. What I am doing, because I want to build nicer things, and why am I not pushing to do it.

What’s in this piece isn’t some kind of pondering that Paul Sellers could also do it, or how Rob Cosman would tell someone to do the dovetails or whether or not it’s hand planed. What’s in it is a shot of high voltage calibration that should enter the thoughts for all of us – if this is something someone can do within a few years, are we sure we’re leaning from the right places?

And it does, of course, make me wonder if I’m doing the right thing putting off furniture making until retirement in favor of knife, tool and instrument making in most cases for now.

if I could do work to this level, it would be entirely by hand, and I would end up making tools to do it. How would you get to this point?

At the very start of this, you would need to study why it looks good, why it’s executed well so far and understand that. Because if you can’t understand or visualize that, you haven’t got much chance making it. And if you’re looking at your tenth honing guide that Lee Valley or LN is releasing and always letting yourself off the hook – think about whether or not you really want to be there, or if you’d like to do as much as you can, even if that’s getting a tenth of the way to a piece like this.

I guarantee there are people reading this who aren’t close to making something like this piece, but what’s missing is information, not talent. And it goes all the way down to solving the little problems with the big ones and telling yourself you can. You can.

This picture was a nice shot in the arm for me – always think about doing better, figuring out what doing better is, how to do better more accurately and more efficiently at the same time. I can’t help you with the bits and bobs in this furniture. I just really don’t feel like talking about saw handles, but if someone had style questions, i could assist what’s generally good and what’s generally not, and you’ll find yourself 80% of the way to good right away rather than 10% of the way there.

And if you have questions about things like setting up or honing an incannel patternmaker’s gouge so that it has a fine sharp edge that doesn’t just chip off, of course I can help with that. We can probably all be better at something for our own investment in ourselves.

But maybe this kind of self reflection and problem solving, and believing we can solve the little problems of making progressively is never going to survive a forum discussion or cycle of magazine articles that goes round and round and round forever below the level of this. it’s all too superficial. We have more within us.

OMG, right into the feelings. I’ve been in this for… well, long enough where expectations towards my work should be way higher, yet I probably can’t do anything like that. It’s not the technical aspect, joinery and surface finishing isn’t a problem, but the overall result would look, I don’t know, wrong? Many aspects of this cabinet is just like 18′ tall brick wall to me, I just don’t see a path between raw material and something like that bureau, well, except maybe sides, sides do look like something I could, lol. I’m not satisfied even with the simplest of my projects, just learned to keep my mouth shut so that people just don’t notice. So yeah, where such people come from and what sources do they use, assuming they didn’t go into formal training. A good example is Tim Cullen (killenWOOD) – he doesn’t make a living from woodworking, right? Yet the things he builds are just mindblowing, and he is very casual about it.

LikeLike

Your comment is on point. I know you could do all of this stuff, though. I know most people could. Whether each of us can figure it out on our own is something different. I have a weakness. I can figure out how to do almost anything, but I am dumb as a stump learning from other people. “You can figure it all out” sounds great, but it also means that there is no just learning something and running with it – I have to figure it out. I’d just and up experimenting to make the raised fronts on this desk and maybe reading to find out what’s applied and what’s integral, but I would need some of that information.

And the skill that I didn’t elaborate on with the wood – knowing it exists somewhere, doing what it takes to find it (that wide mahogany) and paying for it. paying for it is a you can or you can’t. Finding it and doing the due diligence is figuring it out and doing it, though.

My point beyond this, though, is there is room for the people who figure it out, the people who just need to have a fruitful discussion to start building this foundation (the saw handle, the knives, the chisels, the guitars – they are all the same to me – they’re from the same foundation, everything is). the good work can be done by all of us if we can get clued in and start growing things both what we know what we can do (or do well enough to know we want to improve either results or speed), and how to learn going forward – how to find information, resources, etc.

I could’ve built 15 saw handles just to get where George got me in one. And the lesson on the saw handle about lines and curves and transitions can apply to thousands of things. George’s making advice over the dozen years I’ve known him has probably amounted to about an hour of what we’ve talked about – he gave me a little bit, I ran with it and I don’t want to do anything else to waste his time other than bounce things off of him.

But you and I and George and everyone could be a group of hundreds or more with this mindset, pushing the frustrated carpenters and failed furniture makers into another room out of the way when they decide that the discussion is above their head, desires or achievements.

it doesn’t really matter where we all end up – we don’t have to be George, or match the desk here, or whatever, but rather have the opportunity to be pointed in that direction of we want to.

Not stumpy numbs or rex whatever convincing people to buy their 19th plane off of amazon.

LikeLike

Yeah, I don’t think that it takes tons of talent or that one has to be natural born, after all the pieces we admire at museums were done by simple and somewhat random folks. And in most cases practice makes up for talent, so it’s not like it’s all totally out of reach, there’s just some personal traits and circumstances. I’m kinda your opposite in a sense that mostly I learn from people. It helps to overcome some mental blocks and once somebody walks me through a process – I can continue further on my own. This is probably why it’s hard for me to spend money on good lumber (“what if I spoil it?”, “this is great wood so a piece must be exceptional, but I can’t do exceptional things” and so on – extremely hard to battle) and why I’m envy your ability to just go and do it. I’ve witnessed how you started with chisels from pretty much just an idea to a couple of hundreds finished pieces. This is really admirable. So I guess a community of people that can figure stuff and learn or teach each other would totally recover volumes of lost knowledge and even move further and improve the current state of affairs. It’s just these people live all across the nation, so most probably this will never happen.

By the way I decided to register at forums once you mentioned them in one of your videos, so I was kinda late to the party and now most people that really shared really good info are either inactive or gone. And forums are very, very different from what they used to be, it seems a watershed moment was widespread adoption of Internet and a new wave that amplified every voice – before it would take quite a bit of motivation to even get online, not mentioning running a personal website.

LikeLiked by 1 person

Actually, I think the chisel example you bring up is something I like to do, but doing things that way vs. wanting to learn from others is actually a teachable thing, too. It may still not be a preference even if it can be learned, but this all falls into a greater context than I think a lot of people feel that it would. I described guitars and chisels as kind of being the same thing. Furniture is, too – the framework of all of it is what people need to learn. I get along with George because George would address problem solving the same way, though with more access to experts to start from a better starting point. Still, his explanations are almost completely devoid of method.

I treaded water for about four years trying to figure out what I wanted to do thinking I just needed to decide if I was willing to start taking notes of everything and learning “the right way”. Success with one thing was all it took to try to figure things out after that – the whole hand work thing was just knowing how I wanted to work and knowing most of the hand work instruction (Schwarz, Cosman, etc) wasn’t very legitimate for actually working from rough lumber. it didn’t make sense, but figuring out double iron planes (both making and using, or really the opposite order) was on a hunch that how hand tools are taught (cap iron holds the iron in place, close the mouth, send your saws out for sharpening, use a honing guide and accept whatever happens to the edge) didn’t make any economic sense.

but I can offer what I found and so could people who have found the same thing in various slices – like basic truths to carving and results that you have to be able to get (the instructions to sharpen, even from carving instructors, just leave people able to start as a beginner but are fatally underdeveloped in terms of results and time. All of that could be taught separately to people who wanted to be serious about things within a month or two.

LikeLike

> I described guitars and chisels as kind of being the same thing.

Yeah, I agree: there’s one single underlying principle. People that get it are talented in more than one art. Like, a good machinist usually can become a good woodworker, not because they have means and skills to accomplish things, but because they can kinda tune in. Or a musicians are often also good artists or doctors are often into watchmaking, etc. I think the only obstacle that prevents most people into expanding into multiple directions: time. Very few people can afford more than one hobby time wise. I’m keeping myself from veering into model making because I’ll have to drop woodworking or my day job (the latter is most likely, but then I’ll starve)

Also I think the “right way” really depends on personal motives. Like, to me hand tools methods are about the ways of making, I just got curious about making furniture without machinery. So for me it has to be the way pieces were built traditionally, ‘cos it’s not really the piece I’m after, a piece is a byproduct. But there are people that are very result oriented, you know, in books on reproduction furniture if a particular part used to be made with a special plane an author might suggest a quick one off laminated molding plane and just be done with it. So it’s hard to tell what’s right, to me they’re “cheating”, to them I’m just LARPing. And it’s fine as long as we share what we figure, so I could learn something from them and they could pick something up from me. Yet there’s this weird bunch that denies even a possibility of having a conversation like that, because of “forum rules” or something.

LikeLike

I guess some of the reason I think chisels are the same, or saw sharpening, etc, is that I’m not doing much of any of it mechanized. I’ve avoided cut and assemble chisel designs or having a million irons water jetted and then selling them like a stock item because that’s not really making to me. so the guitar and the chisels are the same as i’m making them. I would feel they were different if there was a need to learn how to operate machine tools.

Woodworking makes working steel by hand much more intuitive – the filing, the grinding, the layout, accounting for movement in heat treat.

As for the speculation on how everything was made, it’s nice to be able to make tools, and I think at some level, it’s eventually required if things get fancy, but for the writers arguing about how something is done, I recall someone saying to Warren “how would a hand woodworker make this?” with some kind of curved moulding as if it would be difficult. The expectation was that it would take some kind of scratching tool (agonizing!!) and warren gave about four different ways it could be made by hand and said ” a skilled worker would probably carve it because it’s faster than all of the others ” (and no less neat). I think that ended the discussion because the idea that you could just carve something unusual is far too scary for folks who haven’t done much removal of anything without a jig or guide.

that points back to wanting the results (and i’m in your boat, the making is important – I have a hidden motive for why I want to do it both faster and neater at the same time – I think the more skillfully something is done, the less fiddly it looks, so you can get faster and better looking at the same time with making). I can think of 50 things that could be sold based on peoples’ wants that would sell in quantity – not without risk in every single one, but I would rather spend 2 or 3 hours per making chisels by hand. The making is still the most important part – really desiring something to be nice so that you’ll make things and incrementally improve is also important. It’s really difficult to make something nice if you don’t really want it or want to give it to someone in the end.

LikeLike

Getting good advice is incredibly important. The problem is usually finding it.

LikeLiked by 1 person

Exactly, thus my frustration – the online communities could’ve gone the way of bringing in beginners but curating organized good information for those who want to level up, but they became an outhouse where justification and lack of confidence among many (and lack of economic value to the site owners to allow differentiation and not coddling the ad targets) drove the discussion in one direction and they may have failed to progress just due to change in tastes for hobbies (we don’t have too many 100 person plectrum banjo bands, but at one point, that was wildly popular).

Imagine if you wanted to make pine/dammar varnish and could just see a curated topic area with comments below it about success or add on tips. The curated part of the topic would be able to incorporate additional information.

Eventually, information, for example, about chisels – isn’t going to be received well. When I do a chisel test and it shows that an iles chisel (not a sponsor of the forum) fares better than LV’s chisels (main sponsor) and then I make comments that V11 in general isn’t a great choice for chisels – that would probably end up in a core curated topic area – what makes a good chisel.

Advertisers could follow what’s perceived as good as a cue to make that, but they often would rather just steer the message instead.

And so would beginners who, like when the George issue happened with clenching, really just want to bend the message to what they want rather than bend themselves to wanting to be better or just leave the situation alone if they don’t have progress of the group in mind.

Paul, Chris and Rob Cosman – and whoever else, create these weird groups of weak minded men and women who treat their guru and methods like a religion, and their first reaction is to assault some “old guy who worked at Williamsburg” if their feelings are hurt about their hero.

LikeLike

Yeah, the whole “guru xyz said this” is weird.

When I went through architecture school the most appreciated teachers and critics where always the ones that looked at your projects, and then pointed out what did not work and what could be improved in a constructive and encouraging manner. Most importantly they discussed from the basis of what the student stated they wanted to achieve with the project while still coming with their own perspective. The ones that just came with praise were not as appreciated. There where also the critics who only projected their own agenda on everything and did not really look at what a student was going for, which is useless for someone trying to learn. There were also the ones that could leave students in tears after a review. There are few more or less famous architects who were reviled.

It seems to me that your story about the saw handle is just about that. Constructive advice from the view point of what you were trying to achieve. Which encouraged you to continue. Showing something you made to others is for some people making yourself vulnerable.

Anyways, even if the piece above isn’t what I want to make, a deep dive into the design and construction behind it would still be fascinating. The discussion is not about modernist or classicist furniture, it is what makes a piece look good with in it’s context.

I think one of the problems is just the one you touch on your comment about carving above. A lot of the gadget market is based on scaring people away from trying techniques out.

LikeLiked by 1 person

The saw handle was sort of a step further. I didn’t want the obligation of such good advice, but george had good intentions and pushed me a little. The important thing comparing it to the notions embedded in what you mention is that george didn’t have an agenda other than giving good advice.

But whether it’s a little too much or a little too little – the intention is important and what’s missing is making that the “main line” information on woodworking. Instead, we get references to Sellers or Rex Kruger or something about how to use planes or what to buy, and the opportunity to learn is lost.

Sometimes, for a light user, the burden to use planes properly is too great, and it’s probably the case for such folks that a plane isn’t the right tool. I guess this is the flaw of having a forum split in two – and not splitting is to the benefit of the owners. People who are just getting started often have too high of an opinion of themselves and want to dictate the social aspect and collective sameness. George ran into that.

I remember being a beginner and being kind of sensitive to that, too -finding out that charlesworth was more of a teacher than maker, but then appreciating him for what he was, even though I’ve moved on – mostly in speed and need for different methods. He put bricks in my foundation, and that’s good enough. Even if it takes a beginner 50 minutes to flatten an iron and get a truly sharp edge early on – it’s a huge advantage over not ever knowing what a uniform smooth edge feels like, and something you can always go back and compare what you’re doing against.

If I gather what you’re saying correctly, I also don’t care much for certain design items, but you can still look at them and get an idea of what’s done finely and what you’d do differently as a matter of style. I don’t care that much for danish modern or other “organic” stuff, but you can look at versions of it and separate the good stuff from the bad and use it to grow in terms of what you can see and not see.

More interesting is once you task yourself with this and start thinking “OK, I looked at these two things, and this one looks better, now I have to figure out why”, you can go back to things you’ve seen in life that you thought maybe looked funny and then actually figure out why they do.

An example is a hamer guitar, which was well thought of probably mostly due to early CNC or precise machining techniques in the 70s and 80s when that really hadn’t been typical for guitars. But those guitars and peavey guitars show design lent toward that, which can end up violating rules – especially having an element that unnaturally includes curves to straight lines to create junction points that are geometrically easy to get tight with a machine. And interestingly, those kinds of guitars that are really missing the design sauce are notable and nostalgic for some folks, but they never grow in value like the iconic designs do.

…..and you can get a sense that the nostalgic designs had professional design work done during their evolution. And in fact, in the case of the les paul and fender’s guitars, that’s true.

Short story long, even though I don’t care too much for some designs, I’ll still look over them and see what I can find.

LikeLike

In my opinion, forums and online gurus help you take your first steps in this hobby. I say hobby because if you want to make it a business, forums and gurus are the last places to learn.

I certainly got decent advise when wondering how to sharpen, how to do a particular kind of joint, and a number of other topics. One should not linger in that threshold for long and fall prey to the pseudo-philosophical utterings of some of the gurus or forum personalities.

Once you can saw a piece of wood, the next step is figuring out what do make. I don’t mean saw tills or some dumb Dutch tool chest, I mean a piece of furniture in a style that appeals to you or the person you’re making the piece for.

If I make something for the house, it will be in a style that appeals to me (and my wife, of course.) It’s not so much what joints it will use or what tools will be needed. It’s the final product and how it matches my aesthetic desires that take longer to settle on.

What to make is a difficult question if this is a hobby and not a business. Designing something that is beautiful to my eyes is what I find difficult.

—

I still scan the forums from time to time. There’s really not much there to help you take the next steps forward. It’s novice land (should I buy LN or LV?) and inane questions (what do you use your no. 3 plane for?).

LikeLiked by 1 person

If someone wanted to game the forum system, they could encourage a short term boost in posts by asking people what their favorite tools are.

People will talk at length and show Codger Pants like pictures of a clean shop and tools that are basically unused with no marks on the cutting stuff showing ever touching a grinder.

If you asked a question about things people designed that they are proud of more than once, you wouldn’t get many responses, and same about how to move past posts about dovetails, which hand tool site to join, etc.

I’ve had not so much trouble finding a design and lifting bits from it, but as you say, coming up with a truly original design that you’ll take the trouble to sketch and ponder and then actually make it and have it look wonderful is a very tall order.

I guess it’ll never change. The golden days were 90% filler, but 10% of what was out there was coming from legitimate makers or vendors who were vendors after being enthusiasts, and not people just getting tools off of aliexpress or distributing LN tools in another country. And I guess that’s OK.

I don’t think what does or doesn’t happen on forums has too much with how much actual making people do.

it’s too bad there isn’t a little bit more objective discussion for people who aren’t going to design an original piece – on how to go about choosing next steps and building a skill set that’s durable and adaptable.

LikeLike

(the forums in the old days were loaded with comments about planes being better with more and more weight and thicker irons, though, too, so it’s not like the information was all relevant for people who wanted to do more than plane thin shavings for entertainment. )

LikeLike