I had (have?) a little problem with sharpening stones. It’s not a functional thing for woodworking, though I am probably better at sharpening than I would be without having this little “thing” with stones, and the microscope, and straight razor shaving, and sharpening scissors and axes, and ….anything. Even plastic things with an edge.

But from a lot of exposure, I can identify what’s run of the mill and what’s not. And what’s absurd in price (cough…shapton 30k, anything new from harrelson stanley – my opinion….and so on) for what you’re getting. Not that you can’t make something expensive to make even if the core parts of it are not, but remember you, you can go to 0.1 micron diamonds at low cost and a full pound of linde close graded white alumina at 0.3 microns was $60 the last time I splashed out. it’s so fine that it’s not very dense – it sits in a big tub something like 1/16th of the density of the actual alumina textbook amount itself.

Over time, I’ve kind of lost interest in waterstones because I think they aren’t as practical for most people. They seem practical early on with a guide, but they’re …well, not very convenient for a point and shoot type sharpener with skill. What do they do so well that an oilstone won’t do? Cut fast? They certainly don’t cut faster than a silicon carbide stone with the right oil to flush out particles, and they don’t cut a huge array of steels better than sprinkling loose diamond on a natural stone. Have you seen a waterstone that properly cuts CPM 10V? I haven’t. A slow but wonderful feeling very fine oilstone will cut 10V making it impossible to see under the microscope that it’s even loaded with vanadium carbides that are much too hard for aluminum oxide to cut properly.

Before I go on – there are waterstone I treasure. they all came out of the ground, and in some cases, people have traded something I’m fond of, sold me something maybe they sold because of my excitement, or given in exchange for advice or services. So, on the very slim chance you’re one of a very few people who has done that, I have those stones. They permanently reside here, and I guess when I’m dead, people can figure out what to do with them.

So Why is this about King?

The prince of a King I’m talking about is this stone:

Looks like a ratty old oxidized king waterstone, right? It’s tan.

The writing on the back gives this up as an oilstone. it’s vitrified as far as I can tell – like a Norton stone. It’s also really fine, but I think there’s a skin on it so I can’t tell how fine. It’s in no way, shape or form remotely similar to a Norton fine india and I’m pretty sure I have an old stone that is a norton ultra fine or someone else’s offering of the same. Norton has a stock number for a UF, and that’s the stone we’d all like to have, but I’ve never seen it for sale during the period of time I’ve been a woodworker.

I put some oil on this stone, and once I started using it, the oil went right in.

In fact, all of the Japanese oilstones I’ve gotten other than the ceramic mug type stones that are like a Spyderco white stone have not been oiled or pre-oiled. I’m going to take a shot at that with this one as soon as Vaseline arrives. I usually stand my ground, so I don’t keep Vaseline on hand.

Put differently, these are oilstones, but they seem to be sold allowing for use with water, and they work like shit with water – not the good kind of it, either, more like about as well as a cowpat functions as a frisbee. With oil, they are wonderful. They have a “softness” to the feel that is kind of like soft brick, but other than the white ones in a subsequent picture, they have some feel. I think if folks in japan were not so averse to using oil in stones, these would’ve gotten some footing as an interim stone where there just isn’t much good anything in waterstones -especially natural ones. And yes, I have had huge pure white whetstone size Mikawa nagura. they’re really neat, but they aren’t better than a lot of things that cost $25.

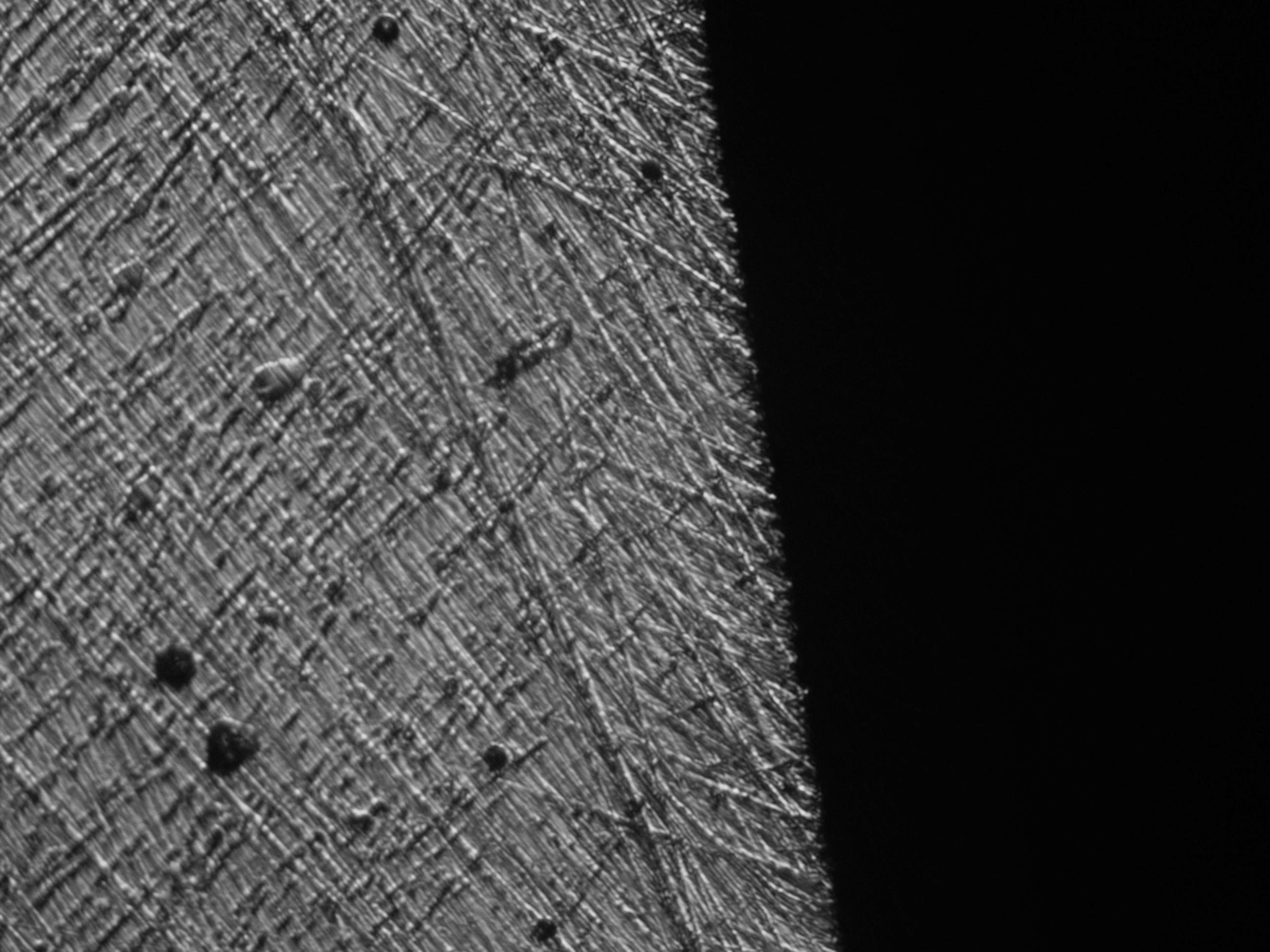

So, what does this do for leaving an edge? After I get some vaseline melted into this thing and then just oil for real, it’ll probably cut a little faster. As it sits, this is what the back of a chisel looks like:

It’s kind of hard to judge that this looks like, but the nature of the stone is it’s touch sensitive. The flat area is bright polish – brighter than 8k. The edge as I see it has no foil without buffing or stropping, just light teasing off of the burr, but it does also not look terribly fine. Just really fine, and it shave shair, but by the polish and the tiny burr, I expected more.

I wanted to get a close up look at 150x with the metallurgical scope, but it definitely is designed for reflective metal stuff, and things like stones absorb a lot of light and this picture looks decent, but i’m sure there is detail missing due to the scattering of the light.

There are no large particles in it, but how fine does the picture suggest it actually is? No clue. Surprised not to see more pore structure given the oil will disappear in it in a fraction of a minute. I have coconut and palm oil on hand, and the palm oil at least is probably pretty stable, but I don’t want to risk soaking the stones with that as it’d be stable for a couple of years, but will it go foul in the longer term? I’ll wait for the Vaseline, but I’m going to make a box for this thing. Vitrified alumina at this level of fineness is not common. Especially in a group of stones that was probably about $100 including shipping from japan. There were about 10 in that group.

Some from that group are here, and some are from prior stone groups. When I was in the throes of buying and sorting and redistributing vintage natural waterstones, I’d get some of these types of stones as a side show thing. As in, for the most part, I never really paid for them in a sense – I paid what I thought the other stones were worth, and the overall average for these probably is $5-$10 per.

The four gray and white stones here are much like a spyderco stone but larger. the top one and the one on the right both are the same – just the front does not say “barber oil stone” on it. they are alumina, very fine, but also are very slow. I see these all the time, but they often look little used and I’d guess for someone used to a waterstone, the operation of them would’ve been confusing. They are a tip of the tool stone.

The prince of a king is in the middle and trials of it made the face filthy. That’s just the way it goes. It’ll be dark once it’s soaked, and look less nice.

Top right is a middle india type stone, also 8x3x1 in size, or thereabouts, and it’s marked 300 vs. the white stones #3000. it is much finer than a norton fine india, so the number on it isn’t meaningful in grit terms that we’re used to. It was, perhaps, relelvant to the old grit scale where 1200FF or something like that was a barber hone abrasive.

In the years after those early 1900s barber hones were made, something changed industrially regarding how fine alumina is made. Precipitating may be the right term, and fine alumina could be had loose. Before that, something like a barber hone must have a glazed surface or it will chew up the edge of a razor in a hurry.

Some of the other red stones here are oilstones, or probably designed to be. Some with a dry vitrified feel and some have a hard but muddy type consistency if you can get something with diamonds on them to abrade them with an oil lubricant. They will go out of flat but not remotely close to as quickly as any Shapton stone, let alone king. The only work of significance I see done with any of these is little grooves from someone sharpening gravers, awls or who knows what – something narrow and hard. obviously, waterstones are not much fun for sharpening gravers or carving tools.

How do you Get These?

I’d never pay a lot for these. You don’t know what you’re going to get- it’s more like a box of cheap stuff and then you see if any is good. They are around in japan on Yahoo (equivalent to our ebay), but someone could want $80 for one, and the next person may sell a pile of them in a group of 20 stones for $60. Beyond just not having anything to return if you don’t like things, you can get a real nasty surprise after you win an auction when you find the proxy services seem to have suddenly lost interest in surface shipping really heavy boxes. A $60 lot of stones suddenly will have air shipping charges of $200. No thanks.

I’d personally put them into a category of if you happen to see one cheap on ebay, maybe. Otherwise, it’s just fun to me to see what was made in different eras, geographies or both.

So, what’s so great about this stone?

LikeLike

It’s an uncommonly fine vitrified stone with some cutting power, and can create a small but fine burr quickly and be followed by very little buffing or compound on a hard surface. It’s sort of like using a washita. I’ll know more in a couple of days once I have it mounted in a box. It’s stuffed with vaseline now and will hold oil on the surface. Sometimes stones like this get glazed and clogged pretty easily and they seem finer than they are, and that’s gone once oil will stay on the surface and present a caked layer from forming.

In fact, a lot of them show up with that caked layer from being used with water. I think that in a country where the medium stones were always waterstones and one that didn’t slurry was a curse, a stone like this one was probably confusing. Water won’t prevent it from caking up.

Unlike waterstones, you can sort of go any direction on it with a chisel and at any pressure level.

LikeLike

Idk, I have a case where nothing worked except water stones: hard tempered Japanese tools. I did get a HSS set of chisels and there were a couple of “haisu” planes in a lot. No matter what I did I couldn’t get them repeatably sharp on oil stones, only after a freshly ground hollow and only so much sharp. I guess it’s because the steel is hard and stones are slow, so I can’t maintain a constant angle for 10 mins at at time – ended up eating the soft layer and with sharp-ish hard steel. Loose diamonds were a plan B, but I just went with water stones and had no problems since then.

Also, it seems that in all the sharpening talks people are focused on the finer side: which stone polishes better, which brand has the finest grade, etc. Is it because the majority uses power grinders for shaping? Gotta admit that with a grinder most of my stones are a decoration now, I can totally get away with one combination India and a strop in 99% of the tasks. But a grinder makes me upset every time: in my cramped space grinding dust is an actual problem — contamination and breathing, — do we have good grinding stones? Nothing of what I’ve tried could get even close to 60-80 grit paper on glass. I’ve tried the Sharpening Supplies giant Crystolon, 3×11″ – doesn’t have uniform density and develops multiple deep dishes very quickly. They send me a couple of replacement stones for free, but they were all the same. Norton coarse Crystolon is uniformly soft, so it makes one big dish very quickly. Also it’s not that fast, I mean, once a honing bevel becomes too large re-establishing a grind bevel on this stone would be quite an endeavor, would definitely require a guide. 220 diamond plate is the coarsest diamond I found, but the grit is usually uneven so it leaves quite deep scratches which are a pain to polish out, like, you can’t skip progression or you’ll spend half an hour trying to get rid of those scratches on a fine stone. Grinding wheels are hard, but they don’t work for manual sharpening, the side of a wheel always feel glazed, even right after dressing it with a diamond. I was thinking about loose abrasive on a wheel, but never got to it. It would be nice to have something like that Sun Child green brick water stone, but as an oil stone.

LikeLiked by 2 people

by the way, the green brick is, of course, some kind of silicon carbide. those are probably about $12 in japan, but who knows what here. Unless i’m not thinking of the right thing and you’re talking about a very large stone. Some of those stones will hold up fine with mineral oil in them or with heated vaseline inserted and then mineral oil, but the ones that don’t, I guess you find out the hard way.

Diamond obsoletes the need for any silicon carbide on the fine side. For some reason, even relatively fine things like silicon carbide razor hones still leave a finer but very ratty gritty feeling edge.

that’s not the reason for this second reply – the coolest and easiest grinding thing I’ve come across so far is a ceramic sanding belt with a water drip. You can be the water drip with a small dollar store type squeeze bottle and hold whatever you’re grinding with one hand. As long as there is water on the sander, there will be a spray of stuff behind it, which you can just confine to a box, but some will come off on you, too.

It eliminates grit in the air, though, at least for the most part. There may actually be a mist of water with some metal in it the same way machinists generate a mist when they cut with a cutting fluid (which can be carcinogenic – that’s likely cheap oils in the past, though, that weren’t refined – not water). I cut all of the bevels on freshly made tools full stop in somewhere around 2 or 3 minutes for a stanley iron on a belt grinder and a drip, that or less on a chisel and then more if there are specialty really thick irons – but nothing else comes close and the water sits on the edge of the tool giving you an indicator. If it bubbles, something is amiss, but it’s still bubbling water on the tool edge, so you’re not losing temper. I can go more into this for regular grinding – a really coarse belt isn’t actually what you want because the water on the belt doesn’t touch the tool.

I think most folks will be put off by the idea of water being slung, though. it beats the hell out of a shop full of dust and burned tool edges. So far, every belt and wheel grinder I’ve used has seen considerable water dripping, and none have any appreciable rust, so so much for that myth.

LikeLike

norton medium crystolon for hand grinding, and in an oil bath. It sheds a lot of particles, makes a lot of swarf and does far better in an oil bath (seek one used if needed). Needs to be newer so that it’s not hard – many of the old ones I come across are too hard to shed their particles. Nothing else is as good for grinding bevels by hand if you have a lot of metal to remove. the coarse is too coarse and finer or harder stones are too slow. Medium crystolon will cut anything that’s steel (probably not carbide). I think vanadium carbides are technically harder but it still abrades the steel well and the details with vanadium carbides are in the final cutting. As in, not cracking them, but rather cutting them.

The issue with HSS on oilstones is carbide hardness – vanadium carbides and to some extent chromium carbides will prevent the abrasive in the natural stones especially from doing much. But vanadium carbides won’t be cut properly by anything in waterstones or oilstones (discard comment about crystolon for fine work – it’s not good for fine work and is messy and contaminating in the finer stones), not india, not shaptons. You may get close, but high speed steel is better death with using diamonds and a great stone for a substrate is one that’s just so slow and fine you haven’t found a good use for it before.

A2 for some reason hates washita, too, and there may be other little nits in different stones that make waterstones easier to deal with at the start. they work. You can use a guide and pull them down the stone, and they’re usually sold in width widths and so on.

Diamonds cut through vanadium carbides easily. Really easily. The only reason you’ll have any trouble with initial sharpness with diamonds would be if you have an HSS tool and it’s not as hard as it should be. if the hardness is in the sweet spot for steels like M2 (64+), fine diamonds will leave nothing or nearly nothing for a burr. A buffer can remove a fine burr if needed and won’t do anything to make a gritty looking finish, but the fine diamonds on wood are also exceptional at that.

If cost is an issue, find the 1-3 or 2-3 -whatever it is – bonding grade diamonds on aliexpress or ebay. 100 grams of them is about $15. You won’t be able to use them in a lifetime. they’re not that fine on a hard substrate or a stone, but on something like softwood, they’ll impart a bright polish and cut through vanadium still, without any issue.

LikeLiked by 1 person

Embarrassing to admin but I still have IM200 new in a box – wanted to reduce the footprint of the sharpening area, but never got to it: realized I ordered an option with 2 crystolons instead of the one with 2 arkansas stones. For whatever reason I though that “coarse India” is an equivalent of “fine Crystolon” – the way they marked their stones is really confusing, one vendor lists a stone as “fine”, but the other lists it as a “medium”. Will remain a mystery for me, I guess. Funny though I had quite a blast with a cheap Smithy tri-hone – I mean, it’s definitely too expensive for what it is, but because their silicon stones are so soft they cut very fast. I went through them in less than 6 months though, only the soft Arkansas is what remains now.

Apparently there are several “green” stones, mine is kinda grayish green – 220 grit by King, “Sun Child” is one of their early brands it seems. It was something around 25$ shipped a few years ago. From what I read online the bright green isn’t for benchwork woodworking, it’s rather for hatchets and sickles where flatness doesn’t really matter, but cutting speed is. Mine not very soft, it dishes, but not much faster than a Norton 1000 stone (people say Nortons are relatively hard, but I have no idea – it’s my first waters tone). Needs a lot of soaking and dries quickly, but it cuts HSS well enough. Not as aggressive as one might assume, even though Japanese grit scale matches ANSI scale in the low numbers, I would say it’s like a coarse India in scratch pattern, only it cuts steels that India doesn’t – so maybe closer to 300 ANSI, and faster because of fresh grit exposure.

The thing about chisels is they don’t really need to go higher than 6k water stone and somewhat ragged edge isn’t a problem. One or two chisels with a great polished edge is enough for situations where a a cut needs to be immaculate – and even then a slicing cut leaves no lines. Planes is a different story though, but the planes with HSS blades aren’t very well made, so most probably they’re roughmedium coarse tools kinda like a better jack plane. I’m yet to make a complete transition, so perhaps with some actual use I’ll have a better idea, but at this point I’m going to sharpen them on diamond plates. They also have their backs ground in the “modern” way, so that it’s almost completely flat with almost no “ura” concavity, pretty sure they will be a bear on the stones anyway.

Re: grinding – my workaround is to get some tools to grind and grind them before leaving the shop for a day. Long term plan is to add an exhaust port to a shroud in some way. I wish I knew about belt grinders earlier. HF has a 1″ belt grinder that I keep for modifying cheap tools like I want them, it’s enough for bevel grinding. But I’m entertaining an idea of making my own low rpm… thing, kinda like carvers use. It’s basically a shaft with a bunch of different wheels on it, I’m pretty sure it can be assembled from McMaster catalogue parts. Besides felt wheels I could use MDF wheels with diamond paste or maybe loose SiCa, get profiled wheels for a bunch of carving gouges and I could glue a ceramic belt on a wheel. Low speed doesn’t spit the grit around and temperature control is easier. For the time being I have a belt stretched on a piece of MDF – flattening backs, sometimes profiling, etc.

LikeLiked by 1 person

I’m thinking more like IM313. Grinding is sort of an exercise of displacement, and the IM313 stones suit it a whole lot better. There is sway in my medium crystolon, but it is bevel side sway and it’s never used anywhere else. The stones are inexpensive enough that you’ll use one perhaps every several years of serious hand tool work and be out about $40.

It’s just a lot easier to knock the bevel back at a slightly shallower angle with a crystolon stone and then work up from there than it is to work with finer stones and work a flat bevel, especially if keen is what you want and a lot of control over where the bevel ends up at the tip.

As far as belts go, you want fast and low pressure. There’s no good belt that will hold up to high pressure work – the ones that do are a tough dull abrasive really meant for grabby or softer materials, and the belts that really excel at hard steel are silicon carbide and ceramic alumina, which depend on speed and low pressure to do their work. At low speed, I think they’ll all disappoint – low speed is the territory of a hard stone that can be refreshed but has a vitrified bond or is white alumina.

Not sure if you’re using japanese blades that are HSS, or the brazed type. The brazed type are crude, and the steel isn’t bohler clean in my experience, but they are fine edge taking blades if the hardness isn’t short, and they are really very good. I would imagine the japanese fare is also. the chisels and such that i’ve gotten from japan that are older are the crude sort of seen everywhere sukemaru type chisels – they’re not inspiring, but they’re pretty decent for what they were when introduced – a $10 or $15 chisel that could be ground. I’d hate to pay someone to put a very clean finish grind on them having faffed with surface finishing high hardness wear resistant steel. It could maybe be done in a more jigged/automated setup now, but even if it was a $10 per chisel tooling and time cost, nobody will do it on even a $100 tool.

I’ve had at least two sets of that type but no longer have any of them, either, and I can’t guess on hardness by feel as well with HSS as I can carbon steel – unless something is really really soft, and then i can guess reliably that it’s not as hard as it should be.

LikeLike

I fell in to the buyee hole, and started surfing around on vintage (and not so vintage) japanese oil stones. The finer ones are fascinating. Also I just love the packaging of the older stones. Also found a bunch of older Norton medium indias in very cute boxes with a bear on. Just lovely.

Will you add this to the omnibus? These finer and midfine (ie betweeen something like a 800-1000 water or worn in fine india and a polishing/finish stone) I find more interesting than the really fine stuff.

Regarding the discussion about grinding. I love my dirt cheap 150 mm 350w grinder, bur it sees very little use since I more or less have to use it on the driveway. My garage is to full of stuff right now and the filth and sparks that it generates is just too much. It only sees use when I have to reshape something, like making a bit for split nuts from a spade bit. I really like Tormeks because they are clean enough to use it in the kitchen if you feel like it. There is a lot of complaints about them being slow online. But I find that if they are used free hand there is no big difference in time for maintenance grinding. Of course they cost a lot of money, but they are well made machines, and Tormek is a company that give great support to their machines.

I would still love to be able to put up a dedicated space for a grinder in the garage.

SiC-belts and 80 grit sandpaper on glass or MDF is probably one of the most useful stuff to have ready in the shop.

LikeLiked by 1 person

I’ll make a note to get more on the omnibus – good idea less than half done. There’s a lot less medium stone stuff on there, though, because it’s not easy to differentiate the fineness of an edge from pictures. For example, diamond hone edges that are really crap to use can look pretty decent. It’s the visual polish level that gets easier to differentiate. But it’s probably the case that everything before the finish stone speed and completion was is more important.

Tormek – I had a supergrind and was also kind of stingy at the time. I didn’t like that the only way to keep the wheel really cutting fresh was to use the truing tool fairly often and just suck up the idea of getting another stone. But it did work just fine if you kept the wheel fresh. I hear it works nicer with a diamond or CBN wheel – generic cbn plus supergrind here puts the whole system with tax on a T8 above $1100, but it does prevent metal particles from getting into the air, and I understand in some shops where insurers don’t want to see a spark, it’s the only real option.

Yes on the dry grinders – my first one was a ryobi grinder from home depot here – $39. 2.2 amps in the US or about 260-270 watts here depending on the voltage in the mains. it had more than enough power to sharpen anything – balance, not so much, but you can clamp or bolt down a cheap grinder. It also had two piece rests, though they were aluminum. A coarse fresh wheel and you can waste a tool away with one without issue. I bought a baldor to replace it just because of some notion of “replacing with quality” and the baldor is a better grinder, for sure – but does it really make a difference? Not really. The latter is about 400 watts and both are severely underpowered if you get into grinding to make tools – but few people are going to do much bulk grinding. Jet had made a bargain priced taiwanese (very good) grinder good for that – a little over 1300 watts – for $260, but the magic of covid and probably greedy bean counters suddenly made the same grinder $470 about three years later. Too bad. That’s a full speed 8″ grinder, also excellent for upkeep grinding but a scary amount of power for someone who is not familiar with how a catch on a grinder could occur. The speed/power and motor momentum would make for an ugly situation. Those grinders have cast hoods and a dust port that does a really good job, but it’s not 100% if that’s a concern. There’s always some metal in the air if the doors are closed, even with port capture or dust capture via a small hood just outside of the grinder.

LikeLiked by 1 person

I hear you about it being easier to diffrentiate finer stones from pictures.

It’s not only the pictures in the omnibus though(though the Dursol/Autosol picture is a must see for anyone interested in practical sharpening!), the comments about the stones are valuable as well. The index of stones it creates is also interesting. If I could be a bit self serving and make a request it would be really interesting to see pictures of all stages in a practical sharpening process. An example could be something like fine india-washita-autosol on wood. Just because it would make it easier for me when I try to teach friends and family how to do basic sharpening!

Re big grinder. I remember the big industrial three phase grinder/polisher we had in elementary school. The shop teacher would let you use it if he thought youcould handle it safely and after telling a few gory and scary stories of what it could do to you if you didn’t use it properly. This was in the 90’s, I don’t know if schools still are brave enough to let a bunch of 13-15 year old kids use stuff like that! There were some kids the teacher didn’t let close to the machine back then, and I can guess why. Teenagers in puberty are kind of stupid, at least I was. At least I was allowed to use the machine.

And I still have some respect since then that carries over in my puny grinder.

LikeLiked by 1 person

I just read on Shaptons site that their kuromaku stones can be used as oil stones. I wonder how that would work.

LikeLiked by 1 person