Not much posting lately. I’ve made a few things, like my first hot formed and hardened chipbreaker as it just seems like a good idea to make an entire plane end to end:

That turned out well, and the first is good enough that the second will be exactly what I want. And it leaves just making screws without machine tools. We’ll see about that.

But turn of the year with some family obligations and kids in their mid to later years of youth before going off to college pinches time.

I don’t need much as far as woodworking goes. I need to buy steel occasionally, and getting rid of unused stuff is more important than getting more, but I did two things in the months before Christmas up through Christmas. I bought a bunch of boots to wear in the shop (did I mention that already?). Some new, some very little used – all US made stuff to try out various pairs. It’s perhaps not normal, but rather than buying a pair or two of shoes a year, I usually buy a glut of shoes every half decade to a decade. If it’s casual work shoes, I’ll track down five pairs and those will go at least ten years if they’re good shoes.

So, the boots are the same. Thorogood moc toes and a pair of redwing heritage boots. I don’t know why I never thought to look closer at them, but it was a chance thing replacing one pair with some heel pain courtesy of daughter getting better at tennis – I can no longer keep up, and putting the boots on to replace one other ratty pair of boots only to find they are more comfortable than any shoes I’ve ever worn. To see how the different boots are made, especially the simplified by really high quality redwing heritage stuff (smaller in profile, with your pants over the laces, they just look like shoes – solves shoes and boots at the same time). Great – it fits something I like to do, which is to make something you have to do something you like to do. You have to shave, or probably do. Shaving with a straight razor is a nice way to do it, one that you eventually look forward to. I need shoes – and dread finding out how crappy the stuff floating around really is as nothing is sacred in shoes.

Anyway, the tools:

I figured I’d like to get a forkstaff plane since I’ve never had one, and I found some from England and bought all three. They seem to be slow movers!! for the uninitiated, hollow sole, bench plane with a double iron. They sell for pennies and would be pretty difficult to make, especially because the cap iron matches the sole profile.

I quacked out one of my good calipers by getting tung oil in it and not noticing it until it was dry, and replaced it for now with two older vintage mitutoyo calipers. I know, no woodworkers need a dial caliper. It’s a nice thing to say. They’re awfully nice to have making tools, though and having older high quality ones that cost the same as new ones that are garbage is a far better idea – you don’t have to fight them or get annoyed with their function. And they’ll do better than new cheap ones even if they’re already used.

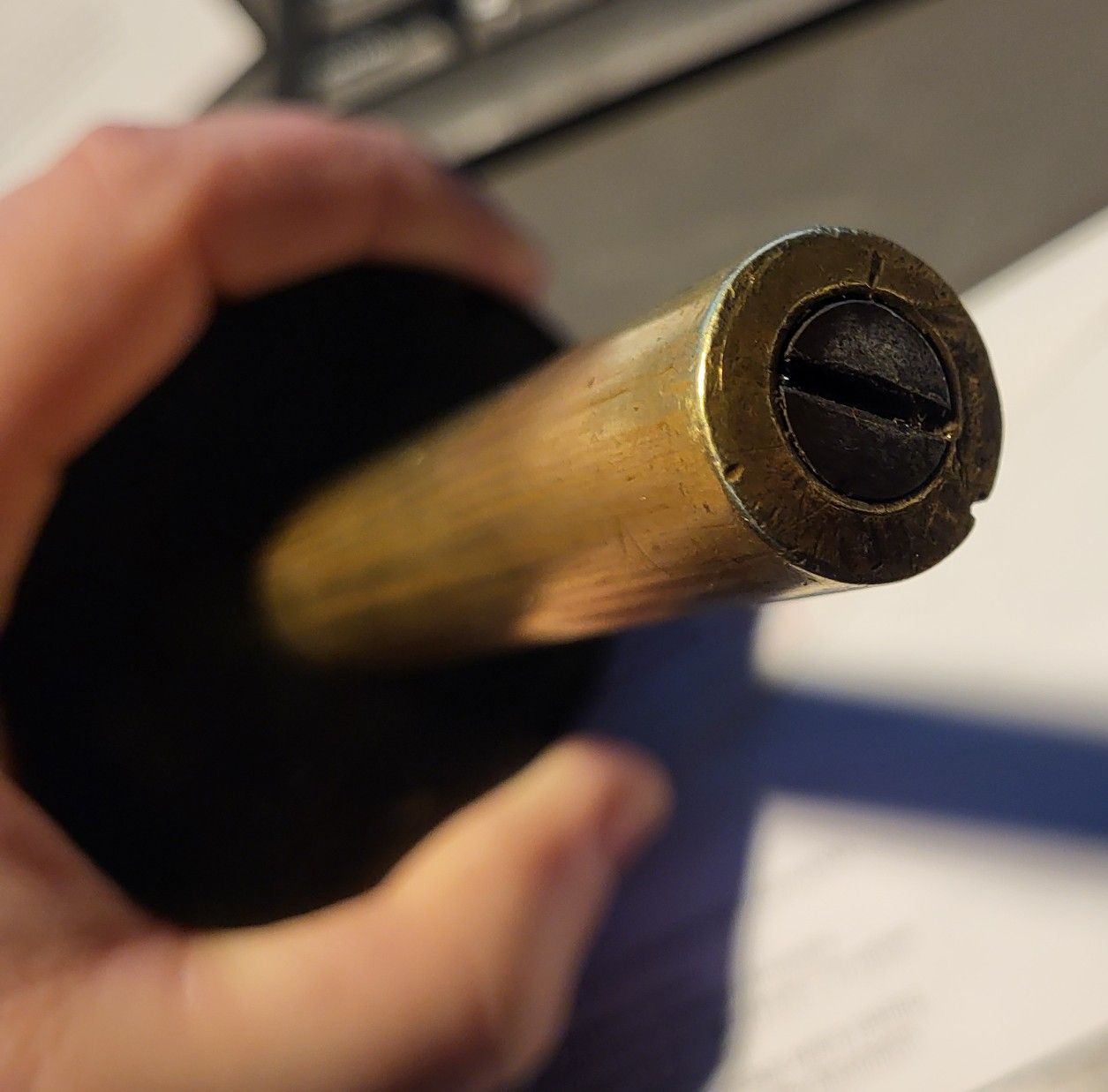

And lastly, I found this style of marking gauge on ebay – I knew there were a couple, but found out later that they’re pretty common:

these were apparently made by marples, but there is no name on them. As far as I can tell, there is a length of threaded rod, but it’s extremely close tolerance with zero slop, and there is some boxwood inside the brass tube.

I can’t vouch for all of them, but this one has the feel of a hydraulic clutch in a car – it is just worlds different than the average mortise marking gage, and it was about $65, I think, to get it shipped here from England. The cost of shipping is really something from England. One seller will ship something like this for $45 and the next $15. The former probably won’t find a buyer in England and because of the shipping, they won’t find one outside of England either.

But this gauge is just dandy, and I really have no interest in making one like it, so it is the rare pickup. Everything on it is just superb, and I can leave it set for 1″ work with my favorite mortise chisel and maybe use the adjustments for sport just to appreciate them.

Jeez

And as I sit here typing this out, I realize I also got a try plane or long plane that’s probably from about 1780-1820 – all depends on whether the iron is original, as well as a pair of ward mortise chisels that I should’ve left in England, but they are the kind of thing that I really thought someone should make, but are really uncommon to find. They’re a sash proportion chisel, but with more height for actual cabinet mortises, and moving toward the oval bolstered type in design – long bevel, tapers, etc, but without the heft.

So, Jeez -I guess I bought more than I could remember at the start of typing this ten minutes ago, but remember now. No wonder there’s a space problem here. I’ll have to check the gig rules for taxes on ebay, because as a never-made-profit type person, the last thing I want to do is unload a bunch of my stuff and then get stuck trying to figure out the value of it to offset the gains. How stupid.

Are dies machine tools? Or you thinking about forging it with a screw die?

This is the story of my life. Wifey be like “have you buying at auctions again?”, and me “I SWEAR I did not… except these 25 obscure tools that I ABSOLUTELY can’t live without”.

Marking gauges are cool, I wanted one at some point. But a few years back I figured a very quick way of making gauges myself. A small drill press or a jig that allows drilling straight at an angle is all it takes. Of course it can be done by hand in a number of ways, just slower. I did 12 gauges in one afternoon and not sure what to do with them now, using only one or two. For some reason I find two beam gauges better for marking mortises. Maybe because I can set it only a hair wider than the chisel itself, which is not very easy to do on gauges where a needle is moved by a screw. Or maybe because I’m marking both walls from a reference edge. I.e. say we do a 1/4″ mortise centered on a 3/4″ piece. Instead of setting it like 1/4″ from the edge + 1/4″ between the pins, I set first beam at 1/4″ and a second at 1/2″, making sure that first pin is just before a tick on a ruler and the second is just barely past a tick.

Oh by the way, the calipers. I think that a woodworker absolutely needs calipers. Everyone knows that a 0.5 pencil line is quite fat, so I’d say fine woodworking tolerance is 0.1mm (how many inches that might be). In order to precisely set to that tolerance (miters and miter-like butts, fitting something into some frame, setting up routers and table saws, etc.) we need a tool that is an order of magnitude better than that. A plastic digital caliper is 6$ or so, they’re really precise. Maybe one steel digital caliper for that one special case once a year. And maybe a cheap vernier double system caliper to use as a scriber. Not dial though, woodworkers aren’t using them often enough to learn reading it quickly, also switching between fractions and decimals in a shop… idk, feels like an extra distraction.

Re: sash chisel: is it like a lighter mortising chisel or the one with a wide and very thin blade? Never actually seen the latter, but I have a sharpened a drywall scraper to pare wide, but narrow areas, something better tempered would work wonders. Interesting though, I found a Korean guy (a National Treasure, no less) using a skiving knife for that. https://www.youtube.com/watch?v=mON5wgXvW4c&list=PLOPAt6-eQGS8mzdEf6paTkIV0Kbul3NGG — it’s a whole playlist of him making traditional frames, in Korean though.

LikeLiked by 1 person

Sounds like the gauges are a success. you know your workflow better than I do, but it’s nice to have an extra gauge or three even in the busiest of exercises where you’ve set a few to a fixed width so that you can avoid resetting gauges over and over. I like the two arm gauges, too, especially among japanese gauges for mortises. They’re just far less fiddly than anything but perhaps the (can’t remember the brand now, but it was expensive) stainless bar japanese gauge where the who bars could lock together. but that also required precise machining of each of the stems for the knives, which seems insane, as well as another screw.

this particular gauge is different than most of the lower cost screw type gauges. the screw is like machinist precise with no slop and you can just set it to anything you can see. Not going to go out and buy a whole bunch of them, but just fascinated that this was apparently a catalogue item, and since marples has a zillion catalogues, it could probably be found to figure out the relative cost (I feel like I may have seen that already, but it’s slipping my mind now)

I do like the dial calipers, but my first introduction to a caliper was for reloading. I think in decimal inches for the most part, but with wood, I measure little but a few main measurements or critical spots and reference the rest. I’ve never really done much with fractional woodworking beyond a 16th or sometimes a 32nd – it introduces error for me, but obviously, some things still are fractional. For example, in my mind is the general approximation that if I’m making a wooden plane, I’ll know the iron size and the plane will be 3/4″ wider on the outside. I always check fractional measurements by converting them to decimal, though, and tend to only work with them when using a rule. I have seen the preference since I started woodworking for a dial caliper with a digital output and dual mode, though – nearing 50, also starting to see eyeball wise why a lot of folks don’t love little dial calipers.

Sash mortise chisels, by the way, are just a type that’s usually about square in cross section, often 1/4-5/16ths ish and usually no taper on the sides of the chisel. I don’t make sash, but understand the taper wasn’t added because the mortises are rarely deep or deep and in hardwood. They seem to have survived indefinitely in the marples catalogue, though for who? I don’t know. maybe for people who repair sash. they are for cutting the entire mortise vs. paring the sides.

LikeLike

Yeah, Marples used to manufacture very high quality tools, just never used this particular gauge. They sure look stylish. A Japanese bar type gauge, even when bars are machined and ground have a little problem: a screw moves bars, because the channel isn’t perfect and there’s usually a pivot point behind a screw. I think they figured it as well, ‘cos modern ones have a channel upside down. Marked up in price accordingly. Two beams type gauge might look primitive, but they’re less fiddly to set up.

My quick way of making gauges is basically a French wedge locking type, except using a round dowel for a wedge – a huge time saver. Getting that narrow and deep mortise right is easily an afternoon job. Drilling is fast though. So just collect materials for fences and beams, lay out where the holes are, drill out beam holes with a Forstner bit, drill wedge holes at an angle (might need a simple jig for a drill press to quickly position at a required angle). That’s pretty much it. It takes 10-15mins to square a large hole and fit a beam. This way it’s totally possible to do a few dozens in just an afternoon. This type of gauge can be operated by one hand, a wedge clamps very tightly from just fingers pressure.

The general idea failed though. I though it would be nice to have a gauge matching a mortise chisel. I realized I have WAY too many mortising chisels, and that every chisel is individual, i.e. 1/4″ chisel is never actually 1/4″, could be off quite a bit. I literally don’t have space to store this many gauges.

The sash mortise I was talking about afaik was for working slots in jambs when weights are installed. Or at least I couldn’t find this narrow a mortise on any sash I saw. They’re referenced in some obscure texts like “Window maker tools” (used to be on Project Gutenberg) and in some old catalogues. I’m not going to fit sash weights any time soon, but this type of tool is useful for a bunch of things we do with a knife or a chisel. Breaking waste from half-laps in thin bars, trimming a bit in a blind corner, scribing, some light paring. Have never seen them on ebay, not even once, searching “sash chisel” usually brings another type, a scaled down version of a heavy chisel. Sorby seems to continue manufacturing it, I heard wooden sash windows are still very popular in UK.

LikeLike